A kind of asymmetric polystar polymer and its preparation method and application

A star-shaped polymer and polymer technology, applied in lubricating compositions, additives, petroleum industry, etc., can solve problems such as limited scope of application, poor high-temperature thickening ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

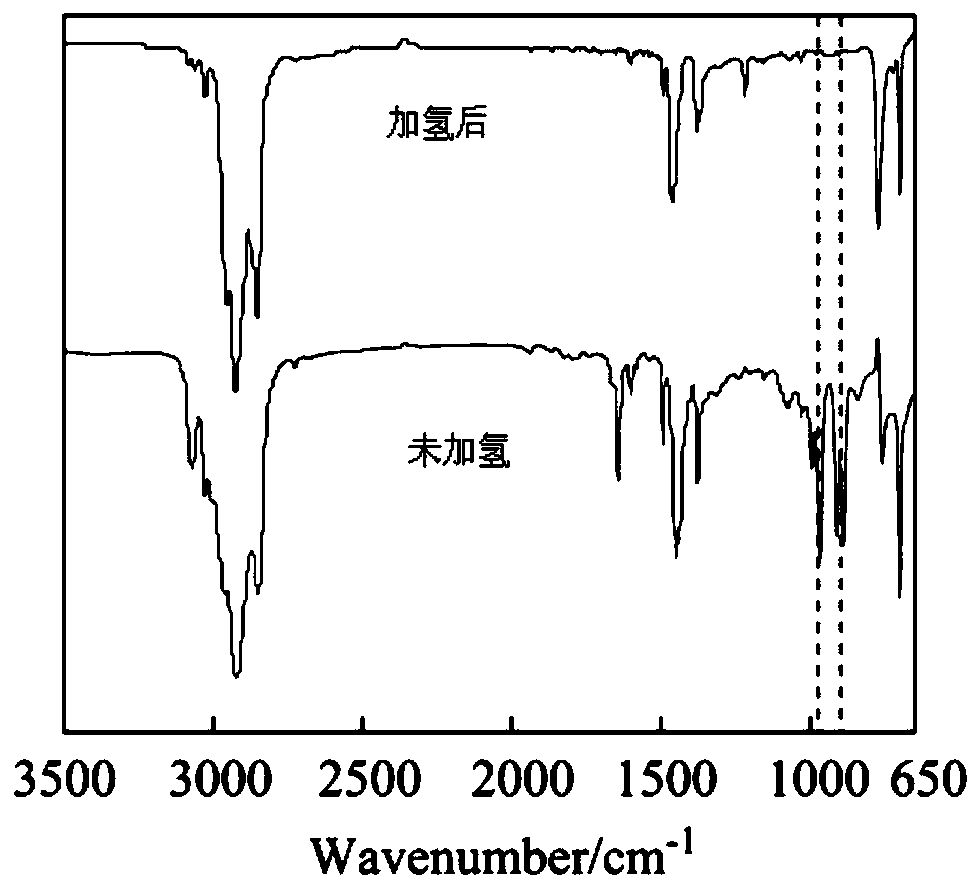

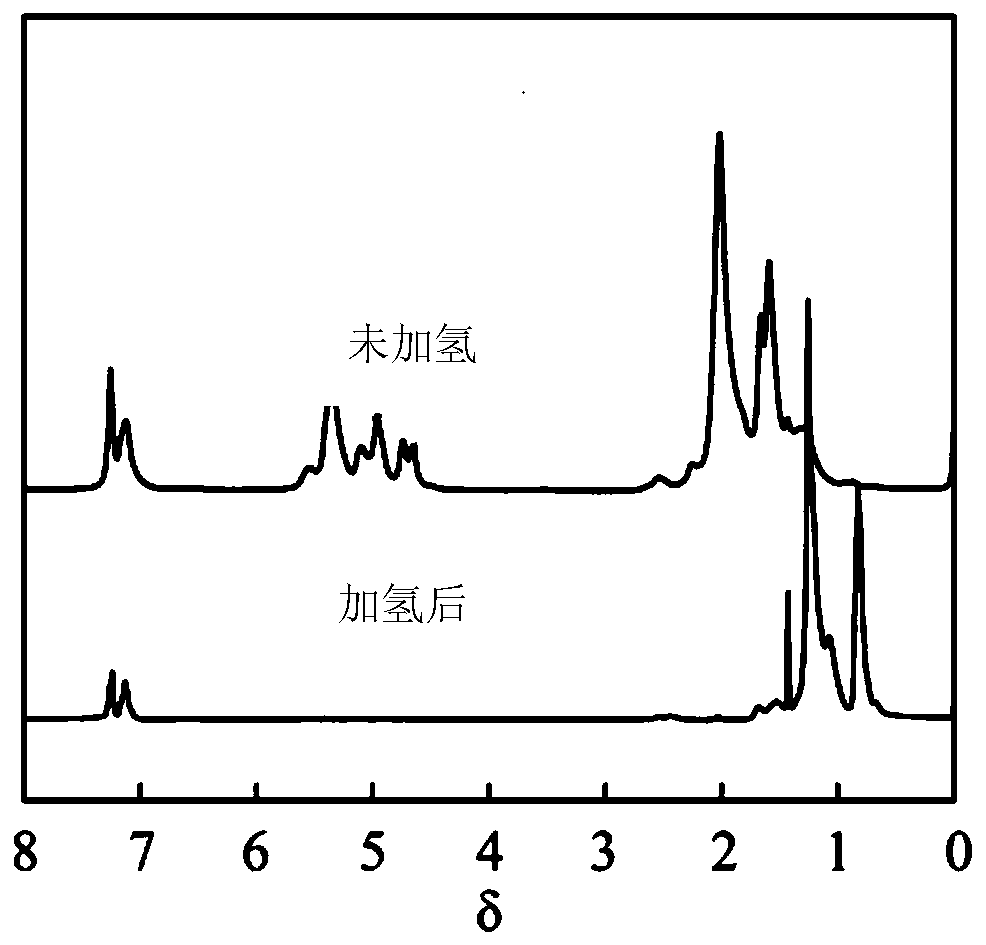

[0025] The present invention also provides a method for preparing an asymmetric multi-star polymer, the method comprising:

[0026] Step 1: In an organic solvent, butyllithium is used as an initiator to initiate the polymerization of isoprene, and then divinylbenzene is added to obtain the active star polymer S1;

[0027] Step 2: In an organic solvent, butyllithium is used as an initiator to initiate the polymerization of butadiene or isoprene, and then add divinylbenzene to obtain the active star polymer S2;

[0028] Step 3: Mix the active star-shaped polymer S1 obtained in step 1 and the active star-shaped polymer S2 obtained in step 2, and then add a coupling agent for reaction to obtain an asymmetric multi-star polymer.

[0029] According to the present invention, in an organic solvent, butyllithium is used as an initiator to initiate the polymerization of isoprene, and then divinylbenzene is added as a coupling agent to continue the reaction. The reaction temperature is p...

Embodiment 1

[0036] In a 100mL flask, under the heating condition of a gas lamp, evacuate and replace with nitrogen for three times to remove impurities such as water and oxygen in the system, and finally cool to room temperature under nitrogen, add 50mL of toluene refined by sodium reflux and distilled refined Isoprene 5mL, refined tetrahydrofuran 0.5mL, n-butyl lithium 0.2ml (1.6mol / L), reaction temperature 50°C, react for 4 hours, then add divinylbenzene 0.2mL, continue to react for 3 hours to obtain active star type polymer S1;

[0037]Another 100mL flask was heated by a gas lamp, vacuumed and replaced with nitrogen for three times to remove impurities such as water and oxygen in the system, and finally cooled to room temperature under nitrogen, and added 50mL of toluene refined by sodium reflux and refined by distillation. 3mL of isoprene, 0.5mL of refined tetrahydrofuran, 0.5ml of n-butyl lithium (1.6mol / L), reaction temperature 50°C, react for 4 hours, then add 0.2mL of divinylbenze...

Embodiment 2

[0042] In a 100mL flask, under the heating condition of a gas lamp, evacuate and replace with nitrogen for three times to remove impurities such as water and oxygen in the system, and finally cool to room temperature under nitrogen, add 50mL of toluene refined by sodium reflux and distilled refined 5mL of isoprene, 0.5mL of refined tetrahydrofuran, 0.25mL of n-butyl lithium (1.6mol / L), reaction temperature 50°C, react for 4 hours, then add 0.2mL of divinylbenzene, continue to react for 3 hours to obtain active star type polymer S1;

[0043] Another 100mL flask was heated by a gas lamp, vacuumed and replaced with nitrogen for three times to remove impurities such as water and oxygen in the system, and finally cooled to room temperature under nitrogen, and added 50mL of toluene refined by sodium reflux and refined by distillation. Butadiene 3mL, refined tetrahydrofuran 0.5mL, n-butyllithium 0.6mL (0.2mol / L), reaction temperature 50°C, react for 4 hours, then add divinylbenzene 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com