Preparation of rubber asphalt mixture

A rubber asphalt and mixture technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as insufficient adhesion performance, poor high temperature performance, and reduced high temperature performance, and achieve improved adhesion and high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Prepare rubber asphalt mixture as follows:

[0024] 1. Add 15% tire rubber powder to 85% road petroleum asphalt (No. 70 road petroleum asphalt) based on the mass percentage of rubber asphalt, and stir and react for 45 minutes at 180°C to make rubber asphalt ;

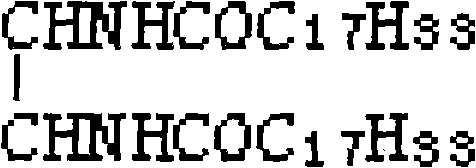

[0025] 2. Heat the stone in 100 parts by weight of mineral aggregates to 160 ° C, add 0.1 parts by weight of N, N'-ethylene bisoleic acid amide, and stir evenly;

[0026] 3. Add 6 parts by weight of the rubber asphalt obtained in step 1 to the mixture obtained in step 2, and stir evenly to obtain a finished composite modified rubber asphalt mixture.

[0027] The stone in the above step 2 meets the following gradation requirements:

[0028] mesh size

Embodiment 2

[0037] Prepare rubber asphalt mixture as follows:

[0038] 1. Add 23% of tire rubber powder to 77% of road petroleum asphalt based on the mass percentage of rubber asphalt, and stir and react for 45 minutes at 200°C to make rubber asphalt;

[0039] 2. Heat the stone in 100 parts by weight of mineral aggregates to 200 ° C, add 0.2 parts by weight of N, N'-ethylene bisoleic acid amide, and stir evenly;

[0040] 3. Add 10 parts by weight of the asphalt rubber obtained in step 1 to the mixture obtained in step 2, and stir evenly to obtain a finished compound modified asphalt rubber mixture.

[0041] The stone meets the following gradation requirements:

[0042] mesh size

[0043] intermittent grading

Embodiment 3

[0051] Prepare rubber asphalt mixture as follows:

[0052] 1. Add 20% of tire rubber powder to 80% of road petroleum asphalt based on the mass percentage of rubber asphalt, and stir and react for 100 minutes at 180°C to make rubber asphalt;

[0053] 2. Heat the stone in 100 parts by weight of mineral aggregates to 180 ° C, add 0.3 parts by weight of N, N'-ethylene bisoleic acid amide, and stir evenly;

[0054] 3. Add 9 parts by weight of the asphalt rubber obtained in step 1 to the mixture obtained in step 2, and stir evenly to obtain a finished compound modified asphalt rubber mixture.

[0055] The stone meets the following gradation requirements:

[0056] mesh size

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com