Method for hydrogenation of medium-low temperature coal tar to produce refrigerator oil base oil

A technology of low-temperature coal tar and refrigerating machine oil, applied in the field of refrigerating machine oil base oil, which can solve the problems of reduced output, poor quality, and inability to stabilize resources of refrigerated machine oil, and achieve the effect of increasing the characteristics of distillate oil and promoting rational utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

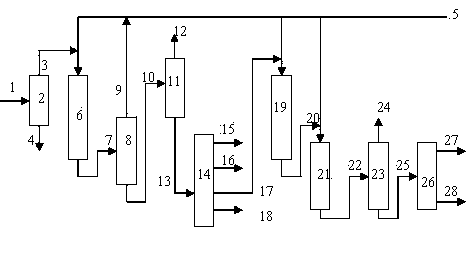

Image

Examples

Embodiment 1

[0037] Datang low-temperature coal tar is used as raw material, and the cut point is 500°C. The specific properties are shown in Table 1. The hydrogenation protection catalyst FZC-103 and the hydrofinishing catalyst 3936 are filled in the hydrotreatment reaction zone, and the filling volume ratio of the hydrogenation protection catalyst FZC-103 and the hydrofinishing catalyst 3936 is 1:4. The hydrogenation upgrading reaction zone is filled with FTX catalyst and FC-28 catalyst, and the loading volume ratio is 1:1. The hydrogenation supplementary refining reaction zone is filled with hydrofining catalyst FV-10. The process conditions and product properties of the hydrogenation process are shown in Table 2 .

Embodiment 2

[0039] Ito medium-temperature coal tar is used as raw material, and the cut point is 500°C. The specific properties are shown in Table 1. The hydrogenation protection catalyst FZC-103 and the hydrofinishing catalyst 3936 are filled in the hydrotreatment reaction zone, and the filling volume ratio of the hydrogenation protection catalyst FZC-103 and the hydrofinishing catalyst 3936 is 1:4. The hydrogenation upgrading reaction zone is filled with FTX catalyst and FC-28 catalyst, and the loading volume ratio is 1:1. The hydrogenation supplementary refining reaction zone is filled with hydrofining catalyst FV-10. The process conditions and product properties of the hydrogenation process are shown in Table 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com