Transformer oil base oil and preparation method thereof

A technology for transformer oil and base oil, which is applied in the petroleum industry, processing hydrocarbon oil, hydrocarbon oil processing products, etc., can solve the problems of limited naphthenic distillate oil resources, low yield of target products, and long process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

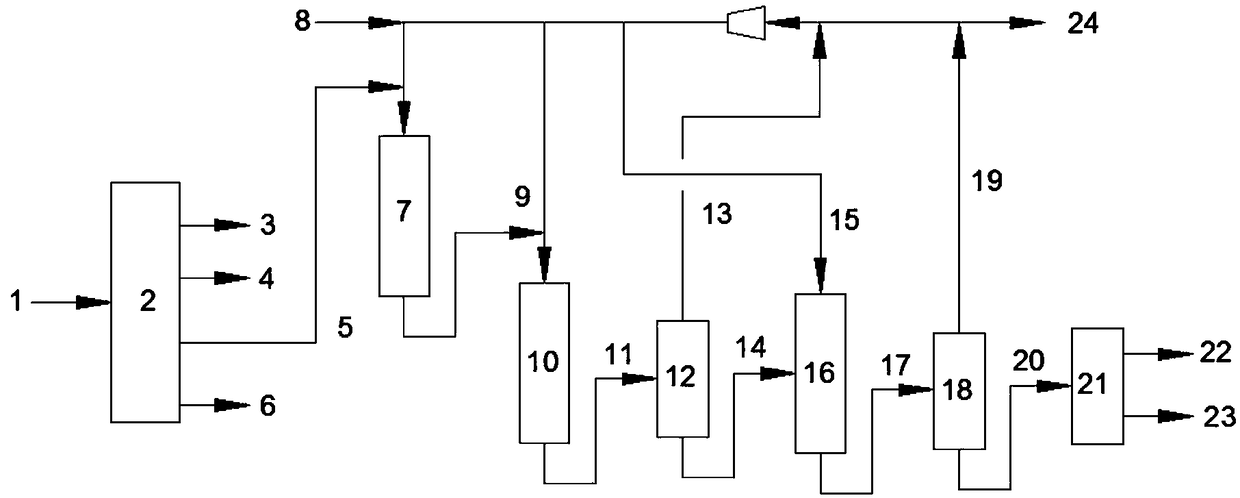

[0080] As described in the background technology section, the existing methods for the preparation of transformer oil base oils cannot solve the problems of long process, high cost, low yield of target product, poor continuity, small processing capacity, limited resources of naphthenic distillates and production The problem of a large amount of environmental pollution (such as acid residue, nitrogen residue, white earth residue). In order to solve the above problems, the present invention provides a method for preparing a transformer oil base oil, the preparation method comprising: 1) fractionating coal direct liquefied oil to obtain a diesel fraction, and the distillation range of the diesel fraction is 290-330°C; 2) subjecting the diesel fraction to hydrogenation refining reaction to obtain a hydrogenation product; 3) subjecting the hydrogenation product to a hydrogenation upgrading reaction to obtain a first transformer oil base oil; 4) subjecting the first transformer oil b...

Embodiment 1

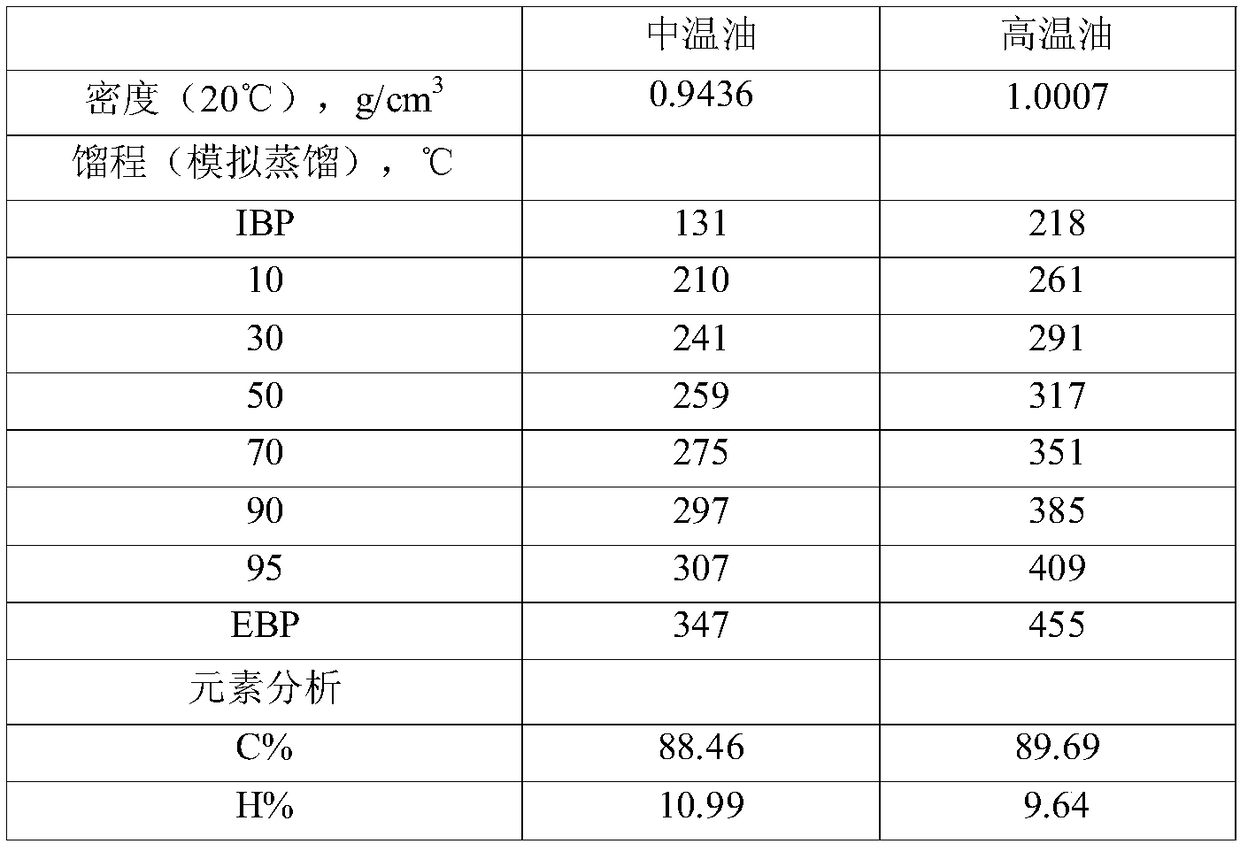

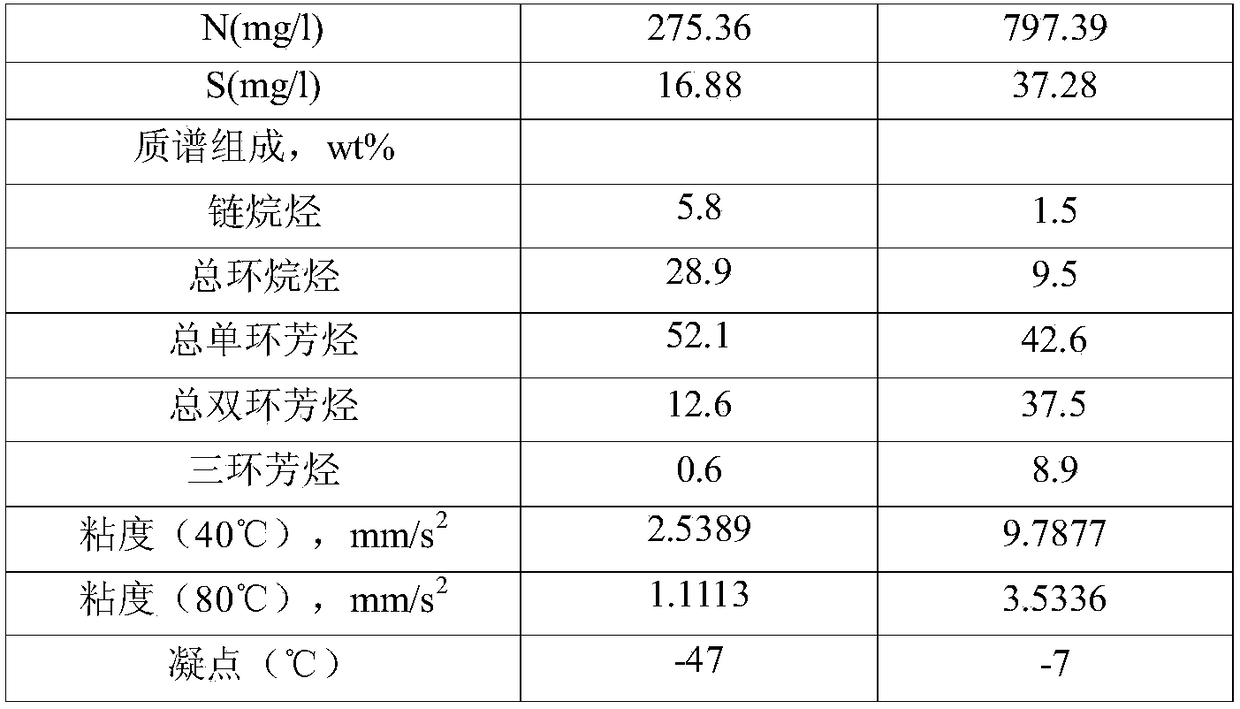

[0103] Shenhua coal direct liquefied oil is used as raw material (coal direct liquefied oil is prepared by mixing medium-temperature oil and high-temperature oil at a ratio of 1:6), and the specific properties of medium-temperature oil and high-temperature oil are shown in Table 1. The hydrogenation protection catalyst RGC-1 and the hydrofinishing catalyst RNC-2 are filled in the hydrofinishing reaction zone, and the filling volume ratio of the hydrogenation protection catalyst RGC-1 and the hydrofinishing catalyst RNC-2 is 1:4. The hydrogenation upgrading reaction zone is filled with hydrogenation upgrading catalyst RCC-1. The hydrogenation supplementary refining reaction zone is filled with hydrogenation supplementary refining catalyst RLF-20. The process conditions and product properties of the hydrogenation process are shown in Table 2 and Table 3.

Embodiment 2

[0105] Shenhua coal direct liquefied oil is used as raw material (coal direct liquefied oil is prepared by mixing medium-temperature oil and high-temperature oil at a ratio of 1:1), and the rest is the same as in Example 1. The process conditions and product properties of the hydrogenation process are shown in Table 2 and Table 2. 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com