Method for hydrogenation of medium-low temperature coal tar to produce large-specific weight aviation kerosene

A technology for low-temperature coal tar and aviation kerosene, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment. Increased oil properties, guaranteed low-temperature performance, and excellent carbon deposition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

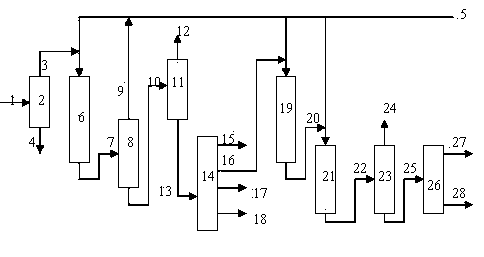

Image

Examples

Embodiment 1

[0038] Datang low-temperature coal tar is used as raw material, and the cut point is 500°C. The specific properties are shown in Table 1. The hydrogenation protection catalyst FZC-103 and the hydrofinishing catalyst 3936 are filled in the hydrotreatment reaction zone, and the filling volume ratio of the hydrogenation protection catalyst FZC-103 and the hydrofinishing catalyst 3936 is 1:4. The hydrogenation upgrading reaction zone is filled with FTX catalyst and FC-28 catalyst, and the loading volume ratio is 1:1. The hydrogenation supplementary refining reaction zone is filled with hydrofining catalyst FV-10. The process conditions and product properties of the hydrogenation process are shown in Table 2 .

Embodiment 2

[0040] Ito medium-temperature coal tar is used as raw material, and the cut point is 500°C. The specific properties are shown in Table 1. The hydrogenation protection catalyst FZC-103 and the hydrofinishing catalyst 3936 are filled in the hydrotreatment reaction zone, and the filling volume ratio of the hydrogenation protection catalyst FZC-103 and the hydrofinishing catalyst 3936 is 1:4. The hydrogenation upgrading reaction zone is filled with FTX catalyst and FC-28 catalyst, and the loading volume ratio is 1:1. The hydrogenation supplementary refining reaction zone is filled with hydrofining catalyst FV-10. The process conditions and product properties of the hydrogenation process are shown in Table 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com