Method and device for producing base oil of naphthene base refrigerating machine oil

A technology for refrigerating machine oil and naphthenic production, which is applied in the petroleum industry, processing hydrocarbon oil, and hydrocarbon oil treatment products, etc., can solve the problems of harsh processing conditions, affecting the economy of upgrading and utilization, and difficult naphthenic oil production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

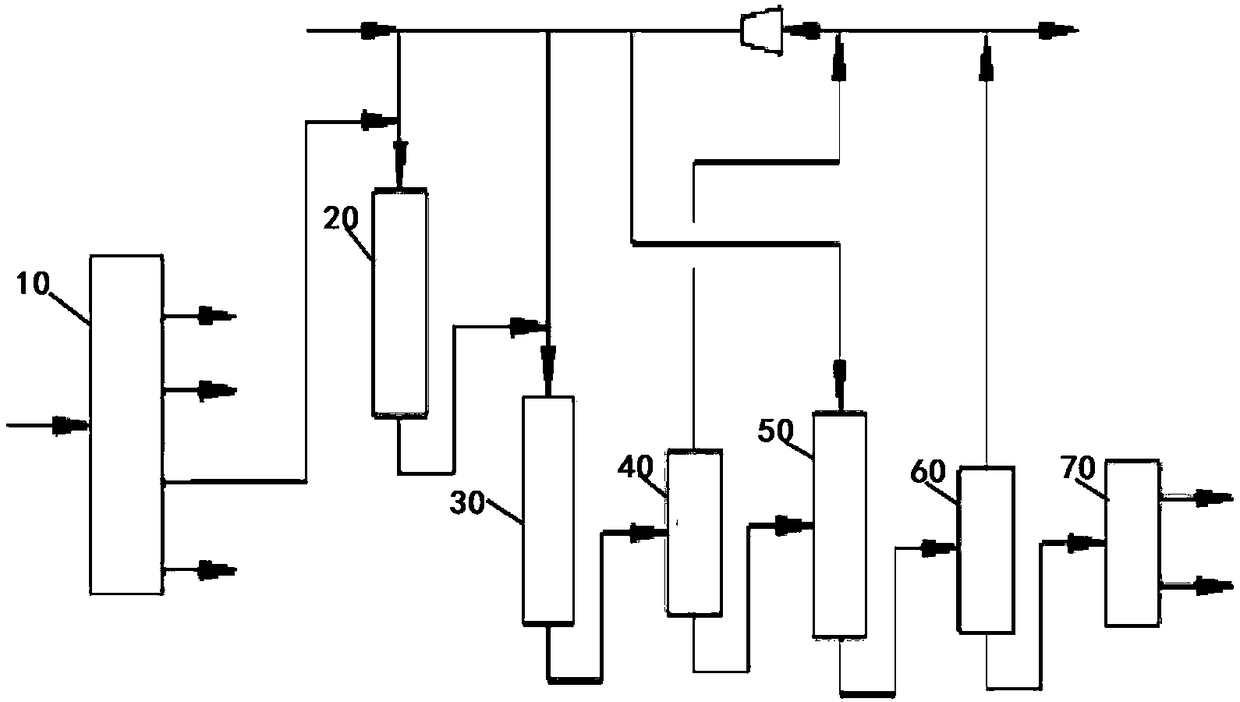

Method used

Image

Examples

Embodiment 1

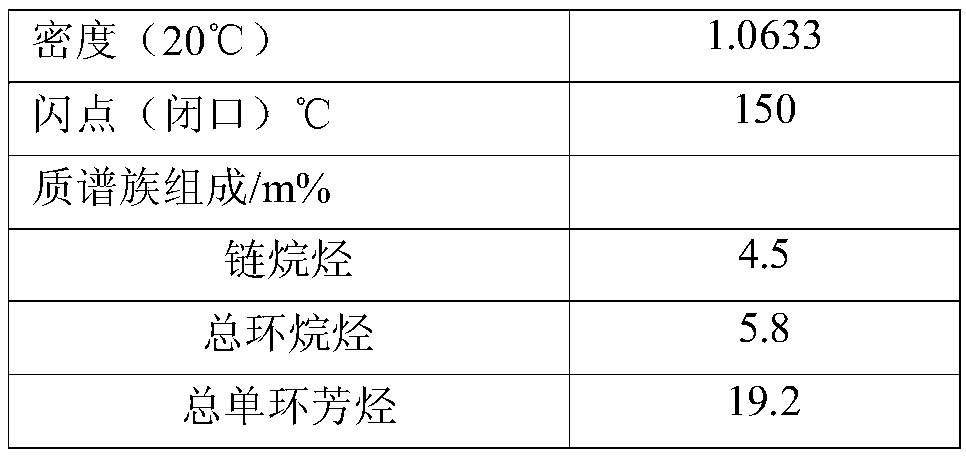

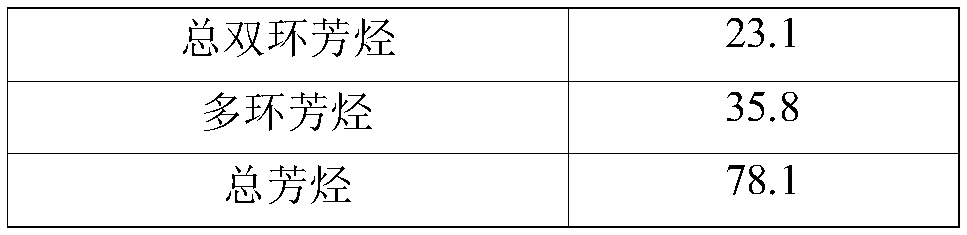

[0062] Shenhua coal direct liquefied oil is used as raw material, and the coal direct liquefied oil is prepared by mixing medium-temperature oil and high-temperature oil at a ratio of 1:6. The specific properties of medium-temperature oil and high-temperature oil are shown in Table 2. The hydrogenation protection catalyst RGC-1 and the hydrofinishing catalyst RNC-2 are filled in the hydrofinishing reaction zone, and the filling volume ratio of the hydrogenation protection catalyst RGC-1 and the hydrofinishing catalyst RNC-2 is 1:4. The hydrogenation upgrading reaction zone is filled with hydrogenation upgrading catalyst RCC-1. The hydrogenation supplementary refining reaction zone is filled with hydrogenation supplementary refining catalyst RLF-2. The process conditions and product properties of the hydrogenation process are shown in Table 3 and Table 4.

Embodiment 2

[0064] Using the same raw material as in Example 1, the difference is that the direct coal liquefied oil raw material only undergoes hydrofining and hydroupgrading processes, and does not undergo supplementary hydrofinishing treatment. The process conditions and product properties of the hydrogenation process are shown in Table 3. ,Table 4.

Embodiment 3-4

[0066] Using the same raw materials and process as in Example 1, but the hydrofining process conditions are different from those in Example 1. The process conditions and product properties of the hydrogenation process are shown in Table 3 and Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com