Lithium iron phosphate material, preparation method thereof and lithium ion battery

A lithium-ion battery, lithium iron phosphate technology, applied in the direction of battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problem of performance stability of mixed materials, no obvious advantages in cost and cycle performance, fast attenuation, and poor cycle performance etc. to solve the incompatibility between high volume density and low-temperature rate performance, improve low-temperature performance, and ensure high-pressure compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

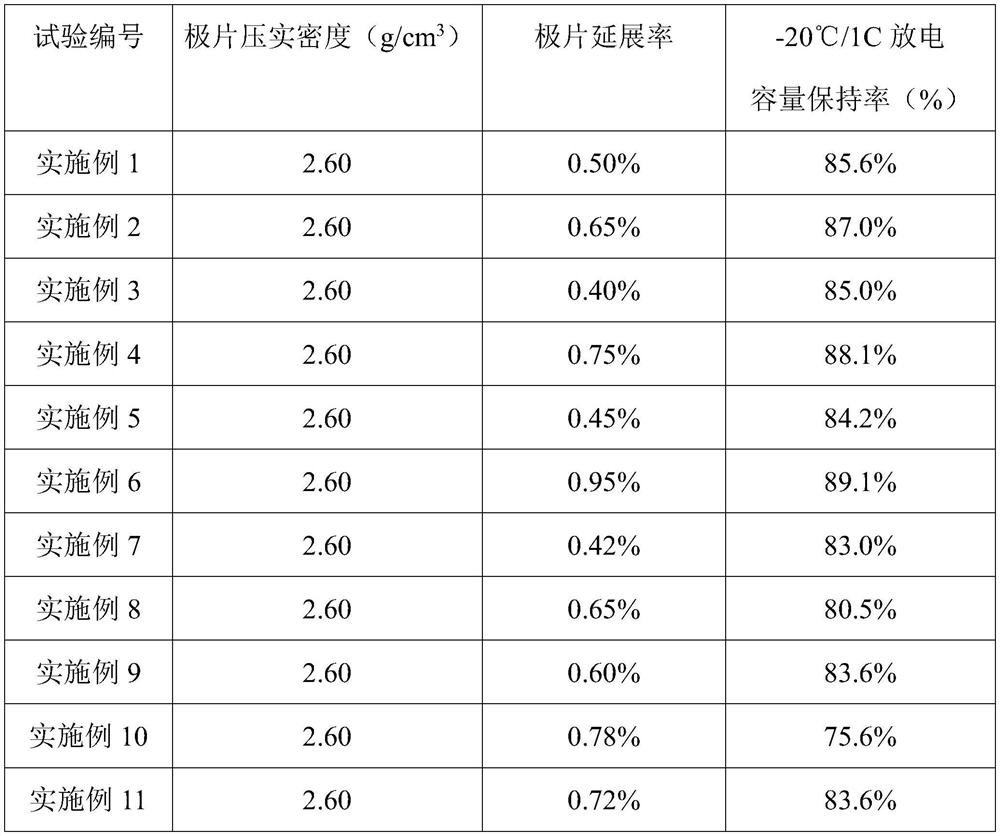

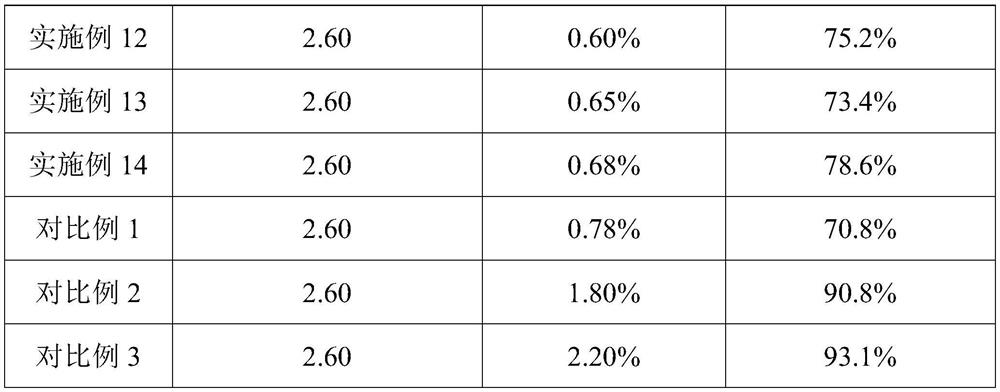

Embodiment 1

[0064] The present embodiment provides a preparation method of a lithium iron phosphate material, and the preparation method includes the following steps:

[0065] (1) Mix pure-phase ferrous phosphide and the first mixed powder, and perform sand grinding to obtain a doped precursor, D 50 is 70nm, and the mass of the pure-phase ferrous phosphide is 2.5wt% of the first mixed powder;

[0066] The preparation method of the first mixed powder comprises: mixing ferrous oxalate, lithium carbonate and phosphoric acid in a stoichiometric ratio of 100:52:1, adding water and grinding to obtain the first mixed powder, D 50 is 0.25μm;

[0067] (2) Mixing glucose and the second mixed powder, performing secondary granulation and calcining at a temperature of 350 ° C for 8 hours to obtain a coating precursor, D 10 1μm, D 50 5μm, D 90 11μm, D 100 is 19.5 μm, and the mass of glucose is 5wt% of the second mixed powder;

[0068] The preparation method of the second mixed powder comprises: m...

Embodiment 2

[0074] The present embodiment provides a preparation method of a lithium iron phosphate material, and the preparation method includes the following steps:

[0075] (1) Mix pure-phase iron phosphide and the first mixed powder, and perform sand grinding to obtain a doped precursor, D 50 is 50nm, and the mass of pure-phase iron phosphide is 0.1wt% of the mass of the first mixed powder;

[0076] The preparation method of the first mixed powder comprises: mixing ferrous oxalate, lithium carbonate and phosphoric acid in a stoichiometric ratio of 90:50:1, adding water and grinding to obtain the first mixed powder, D 50 is 0.2μm;

[0077] (2) Mixing glucose and the second mixed powder, performing secondary granulation and calcining at a temperature of 300 ° C for 12 h to obtain a coating precursor, D 10 is 0.3 μm, D 50 2μm, D 90 is 5.1 μm, D 100 is 10 μm, and the quality of the glucose is 1wt% of the second mixed powder;

[0078] The preparation method of the second mixed powder...

Embodiment 3

[0084] The present embodiment provides a preparation method of a lithium iron phosphate material, and the preparation method includes the following steps:

[0085] (1) Mix the glucose and the second mixed powder, carry out secondary granulation, and bake at a temperature of 400 ° C for 6 hours to obtain a coating precursor, D 10 2μm, D 50 10μm, D90 11μm, D 100 is 15 μm, and the quality of the glucose is 10wt% of the second mixed powder;

[0086] The preparation method of the second mixed powder comprises: mixing ferrous oxalate, lithium carbonate and phosphoric acid in a stoichiometric ratio of 110:55:1, adding water and grinding to obtain the second mixed powder, D 50 is 0.3μm;

[0087] (2) Mixing pure-phase ferrous phosphide and the first mixed powder, and sanding to obtain a doped precursor, D 50 is 0.1 μm, and the mass of the pure-phase ferrous phosphide is 5wt% of the first mixed powder;

[0088] The preparation method of the first mixed powder comprises: mixing ferr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com