Method for regulating and controlling microscopic structure of steel rail welding joint

A technology of welded joints and microstructures, which is applied in heat treatment process control, furnaces, heat treatment equipment, etc., can solve the problems of few invention patents, and achieve the effect of convenient operation, simple process flow and remarkable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

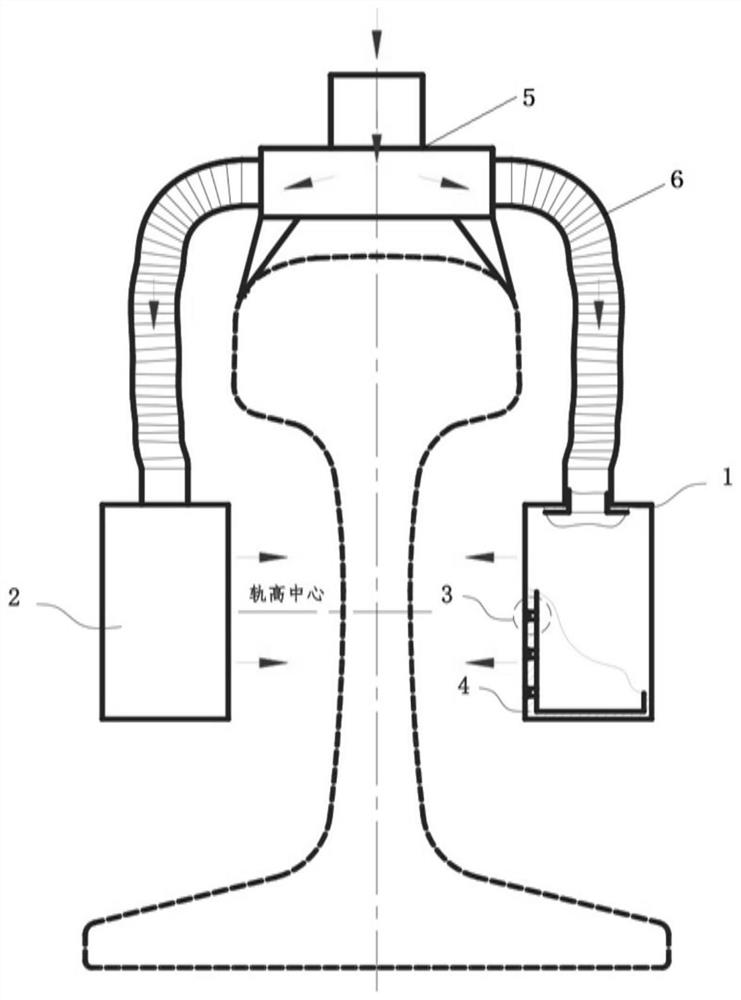

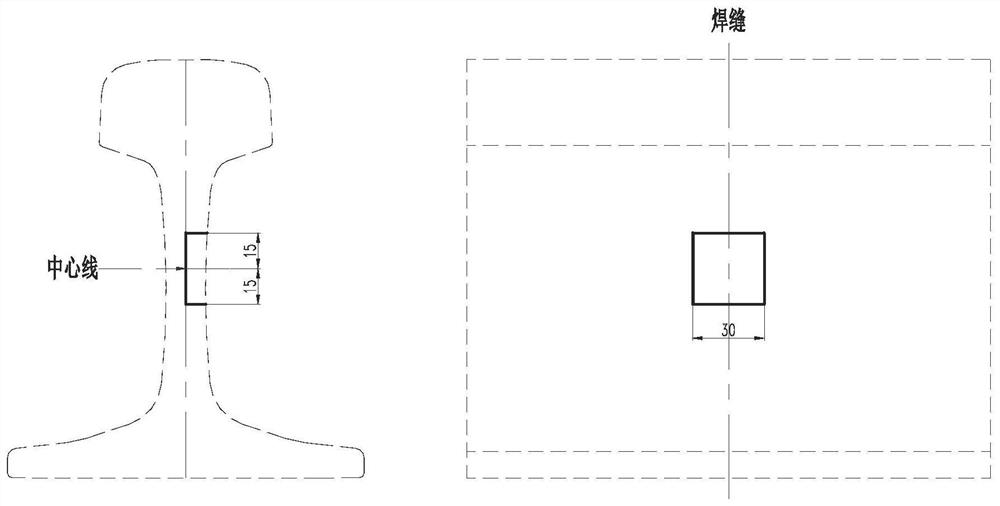

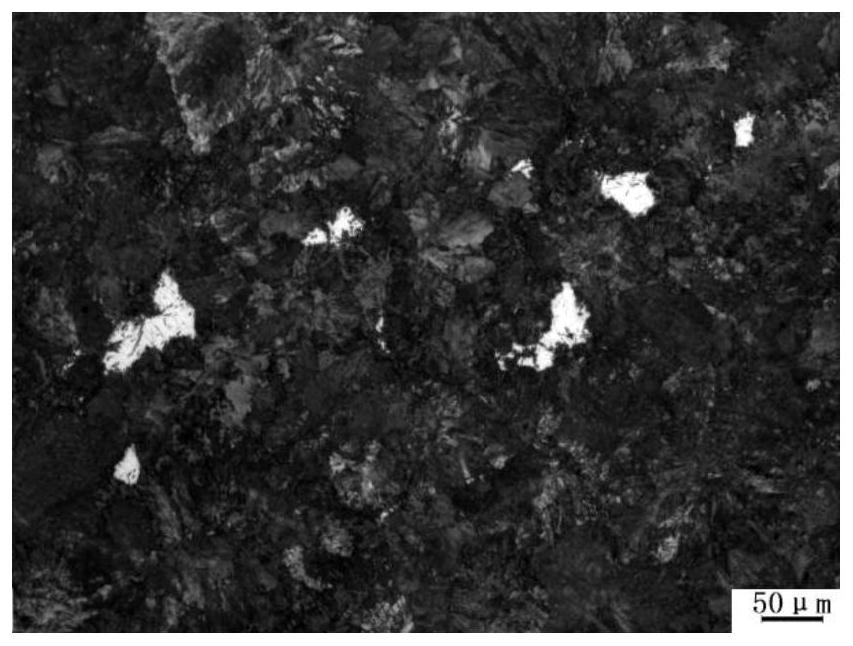

[0065] The experimental material of this embodiment is the 68kg rail profile and rail head hardened (heat-treated) pearlitic rail specified in the AS 1085.1: Railway track materials, Part 1: Steelrails standard, and the measured carbon content of the physical chemical composition of the rail is 0.8% by weight. Carry out 5 parallel experiments, the specific experimental process includes the following steps: use GAAS80 / 580 rail fixed flash welding welding machine to carry out welding experiments, use accelerated cooling device 2 (cooling surface 4 is 13mm away from the rail waist surface, and the spray angle is 45 °), using Water mist (pressure 2.5bar) is used as the cooling medium, and the first-stage accelerated cooling is performed on the rail waist of the welded joint to be cooled obtained by flash welding (the cooling rate at the center of the rail waist weld is 19-35°C / s), While cooling, use an infrared thermometer to measure the temperature at the center of the rail waist ...

Embodiment 2

[0067] The experimental material of this embodiment is the 68kg rail profile and rail head hardened (heat-treated) pearlitic rail specified in the AS 1085.1: Railway track materials, Part 1: Steelrails standard, and the measured carbon content of the physical chemical composition of the rail is 0.8% by weight. Carry out 5 parallel experiments, and the specific experimental process includes the following steps: adopt the rail mobile flash welding machine to carry out the welding experiment, use the accelerated cooling device 2 (cooling surface 4 is 13 mm away from the rail waist surface, and the spray angle is 45 °), and use water mist ( The pressure is 2.5bar) as the cooling medium, and the first stage of accelerated cooling is performed on the rail waist of the welded joint to be cooled obtained by flash welding (the cooling rate at the center of the rail waist weld is 19-35°C / s). At the same time, use an infrared thermometer to measure the temperature of the center of the rai...

Embodiment 3

[0075] The experimental materials in this example are the 60E1 rail profile specified in the BS EN 13674-1: Railway applications–Track–Rail, Part 1: Vignole railway rails 46kg / m and above standard, the R260 hot-rolled pearlitic rail, and the rail solid chemistry Composition The measured carbon content was 0.6% by weight. Carry out 5 parallel experiments, the specific experimental process includes the following steps: adopt the rail mobile flash welding machine to carry out the welding experiment, use the accelerated cooling device 2 (cooling surface 4 is 15mm away from the rail waist surface, and the spray angle is 40°), use water mist ( The pressure is 3.5bar) as the cooling medium, and the first stage of accelerated cooling is performed on the rail waist of the welded joint to be cooled obtained by flash welding (the cooling rate at the center of the rail waist weld is 19-35°C / s). At the same time, an infrared thermometer is used to measure the temperature of the center of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com