Fine crystal non-quenched and tempered steel for connecting rod

A non-quenched and tempered steel, fine-grained technology, applied in the field of fine-grained non-quenched and tempered steel and micro-alloyed non-quenched and tempered steel, can solve the problems of weakening the economy, affecting the fatigue performance of parts, and ductile fracture in the ferrite region.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

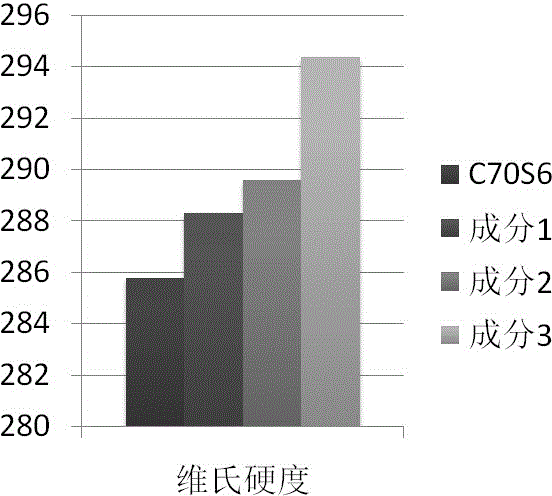

[0023] According to the chemical composition range of the above design: three furnaces of the steel of the present invention and one furnace of comparative steel were melted on the high vacuum non-consumable arc melting equipment. The chemical composition of Invention Steel 1 is: (Ti+Nb) 0.1%, C 0.3%, Si 0.60%, Mn 0.75%, P 0.08%, S 0.05%, Cr 0.10%, V 0.05%, B 0.0005%, Fe quantity. The chemical composition of Invention Steel 2 is: (Ti+Nb) 0.15%, C 0.40%, Si 0.65%, Mn 0.80%, P 0.09%, S 0.06%, Cr 0.15%, V 0.15%, B 0.0007%, Fe quantity. The chemical composition of Invention Steel 3 is: (Ti+Nb) 0.20%, C 0.45%, Si 0.70%, Mn 0.9%, P 0.10%, S 0.07%, Cr 0.20%, V 0.25%, B 0.001%, Fe quantity. The chemical composition of the comparison steel is: C 0.72%, Si 0.32%, Mn 0.57%, P 0.02%, S 0.06%, Cr 0.17%, V 0.03%, Fe balance.

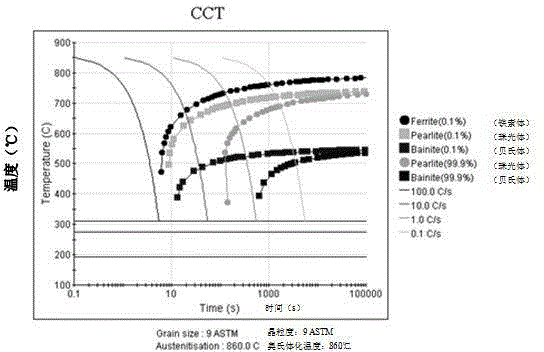

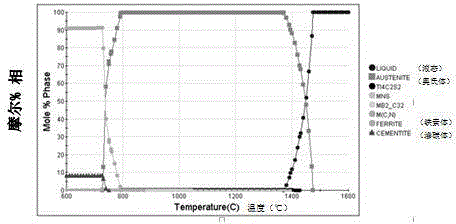

[0024] With the help of J-MatPro thermodynamic software, the phase diagram and CCT curve (continuous cooling transformation curve of supercooled austenite) of ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com