Vertical vibration isolation spherical steel support with lever assemblies

A spherical steel and lever technology, applied to bridge parts, bridges, buildings, etc., can solve the problems of vertical bearing capacity, quality stability, vibration isolation performance and life defects, etc., achieve small friction coefficient, reduce vertical stiffness, The effect of ensuring fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

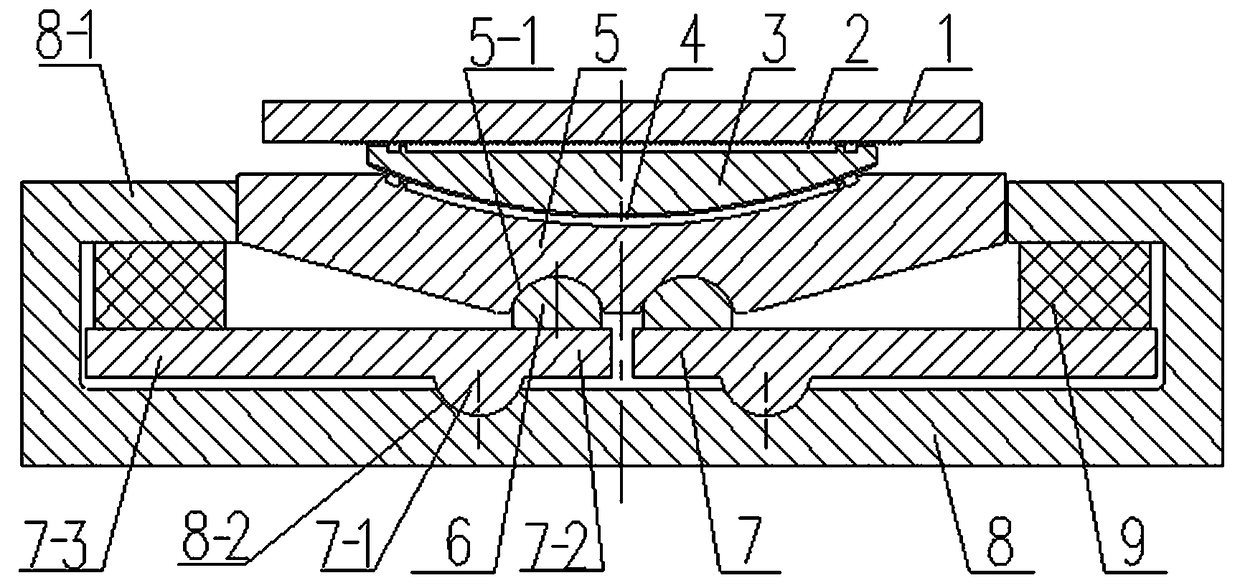

[0014] Spherical steel bearings can be functionally divided into ordinary spherical bearings and hyperboloid spherical vibration isolation bearings (or friction pendulum ball vibration isolation bearings). The support is divided into three types: one-way movable type, multi-directional movable type and fixed type. Pot-type rubber bearings, spherical bearings, hyperboloid spherical vibration isolation bearings (or friction pendulum ball vibration isolation bearings) and other types of bearings can all add the lever assembly of the present invention to change the lower seat The structure of the plate and the base plate realizes the vertical vibration isolation function.

[0015] A vertical vibration-isolating spherical steel bearing with a lever assembly, the lower seat plate 5 and the base plate 8 of the spherical steel bearing are arranged up and down, and the two sides of the base plate 8 are respectively provided with stoppers 8-1, two stoppers. The sides of the block 8-1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com