Relay and its manufacturing method

A relay and drive technology, applied in electrical components, electronic switches, pulse technology, etc., can solve the problems of unreasonable structure and high yield of MEMS relays, and achieve the effects of high reliability, stable electrical performance, and increased torsional strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

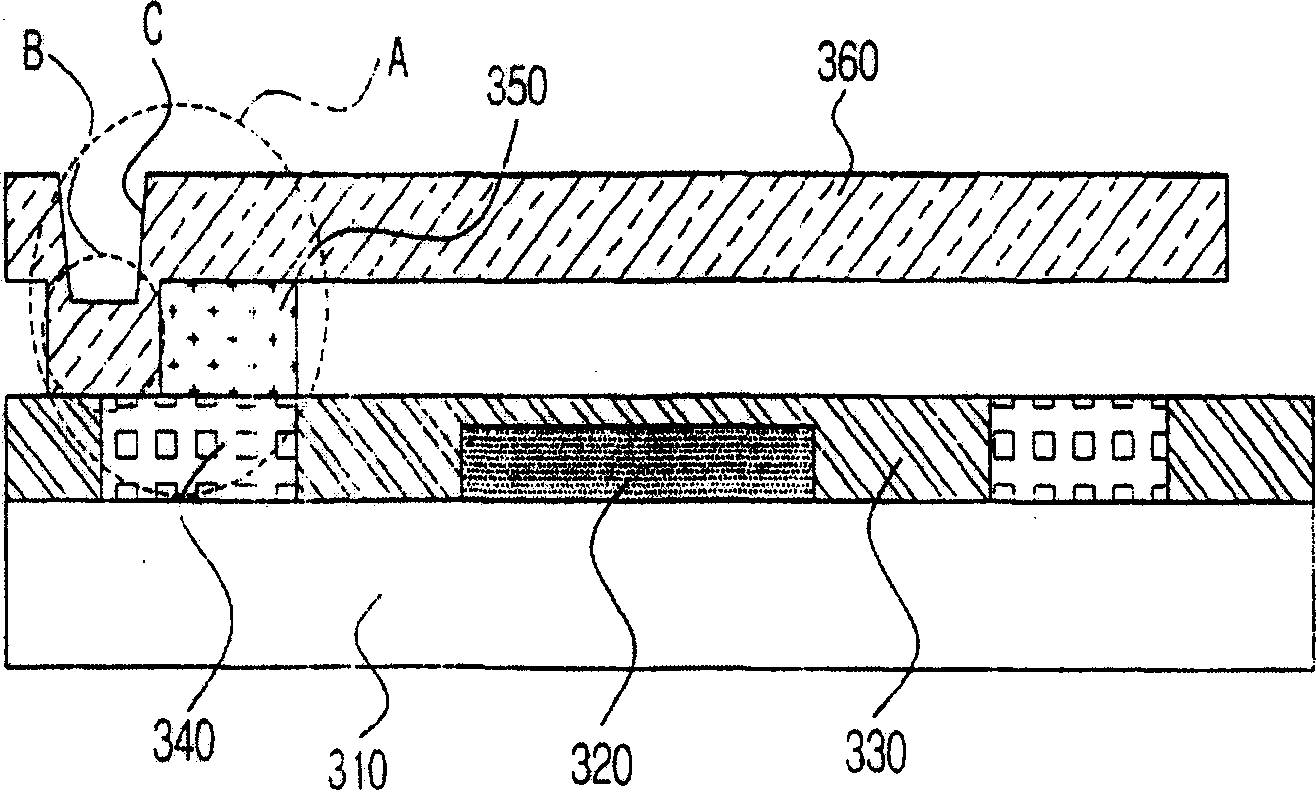

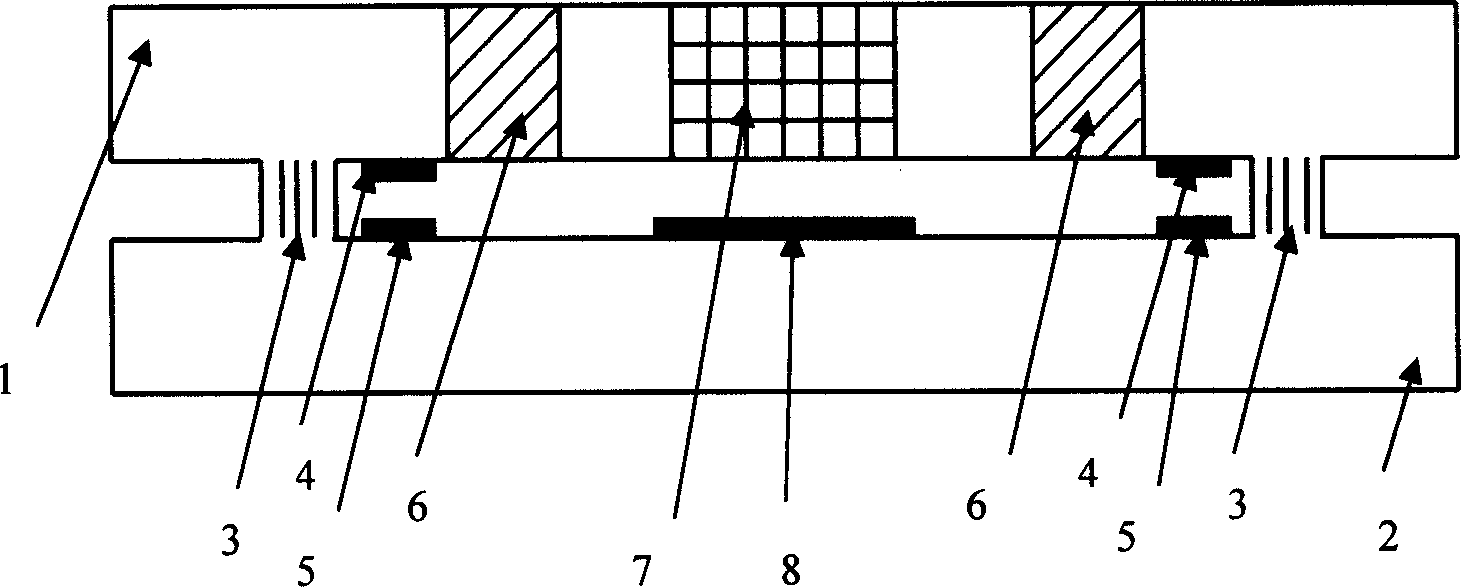

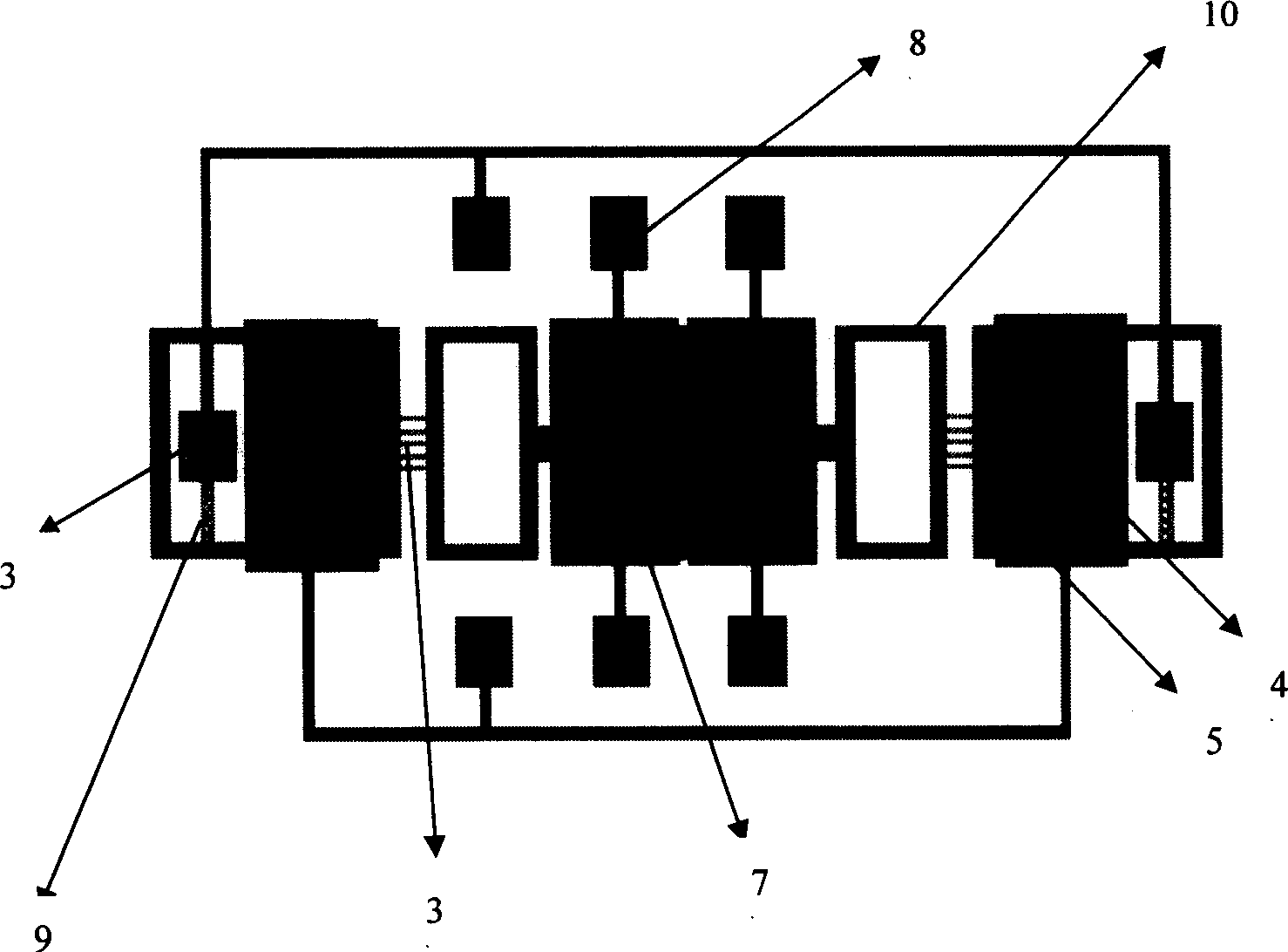

[0064] refer to figure 2 , image 3 , the relay structure of the present invention is generally divided into an upper silicon structure part and a lower glass structure part, and the upper silicon structure part includes: a single crystal silicon structure plate 1 with an anchor point (Anchor) 3 and a beam structure 9, a single crystal silicon structure plate 1 is provided with an upper-level plate driving metal plate 4 and a switch upper-level plate 7, and the beam structure 9 of the monocrystalline silicon structural plate is T-shaped, π-shaped beam or other forms, and adopts a T-shaped, π-shaped beam or groove-shaped beam structure, which can be The vertical stiffness of the beam is directly reduced, and the torsional stiffness of the beam is increased, so that the pull-in voltage of the relay is reduced, and the switching performance of the relay is improved. At the same time, in order to ensure that the devices are structurally connected and electrically isolated, a pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com