Novel metal bipolar plate surface modification method

A metal bipolar plate and surface modification technology, which is applied to the surface coating liquid device, special surface, pretreatment surface, etc., can solve the problem of reducing the service life of the metal bipolar plate, reducing the battery output power, and increasing the internal energy of the battery. To improve the corrosion resistance and interfacial bonding, increase the internal resistance of the battery, and reduce the internal resistance of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

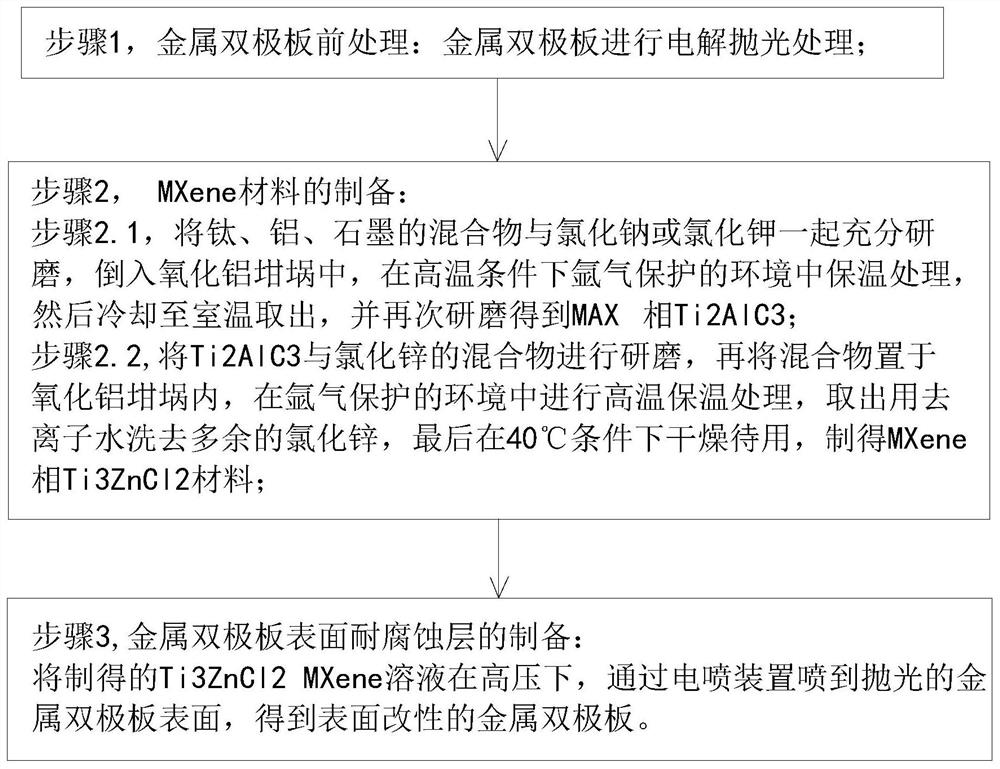

Method used

Image

Examples

Embodiment 1

[0049] The stainless steel bipolar plate was first cleaned with isopropanol, then washed again with deionized water and dried for use. Using methanesulfonic acid (70%) and methyl ethylene glycol (30%) as a mixed electrolyte, at room temperature, the workpiece is 100mA / cm 2 The polishing treatment was carried out for 10 min (minutes) in the current density. The polished parts were washed with deionized water again to remove the residual electrolyte on the stainless steel sheet and dried in the air. Corrosion current I in simulated PEMFC corrosion environment corr ≤1μA / cm 2 , the cathode I after electropolishing corr down by more than 50%. The corrosion potential E of the polished sample relative to the untreated sample at the cathode corr There is a 0.05A ~ 0.08A increase. on the cathode I cor drop and E corr The increase of shows that electropolishing treatment can effectively improve the corrosion resistance of stainless steel.

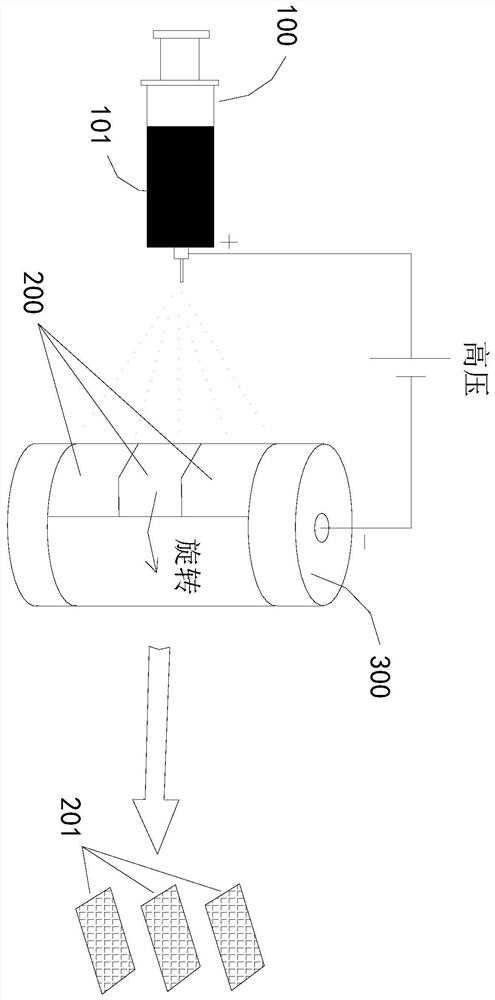

[0050] Such as figure 2 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com