Spring damping synergistic vibration/shock isolating and reducing device

A technology of spring damping and insulation reduction, which is applied in the direction of shockproof, protective buildings/shelters, building components, etc. It can solve the problems of poor sealing performance of viscous damping, affecting structural performance, unstable performance, etc., and achieves good sealing performance. Excellent vibration isolation and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

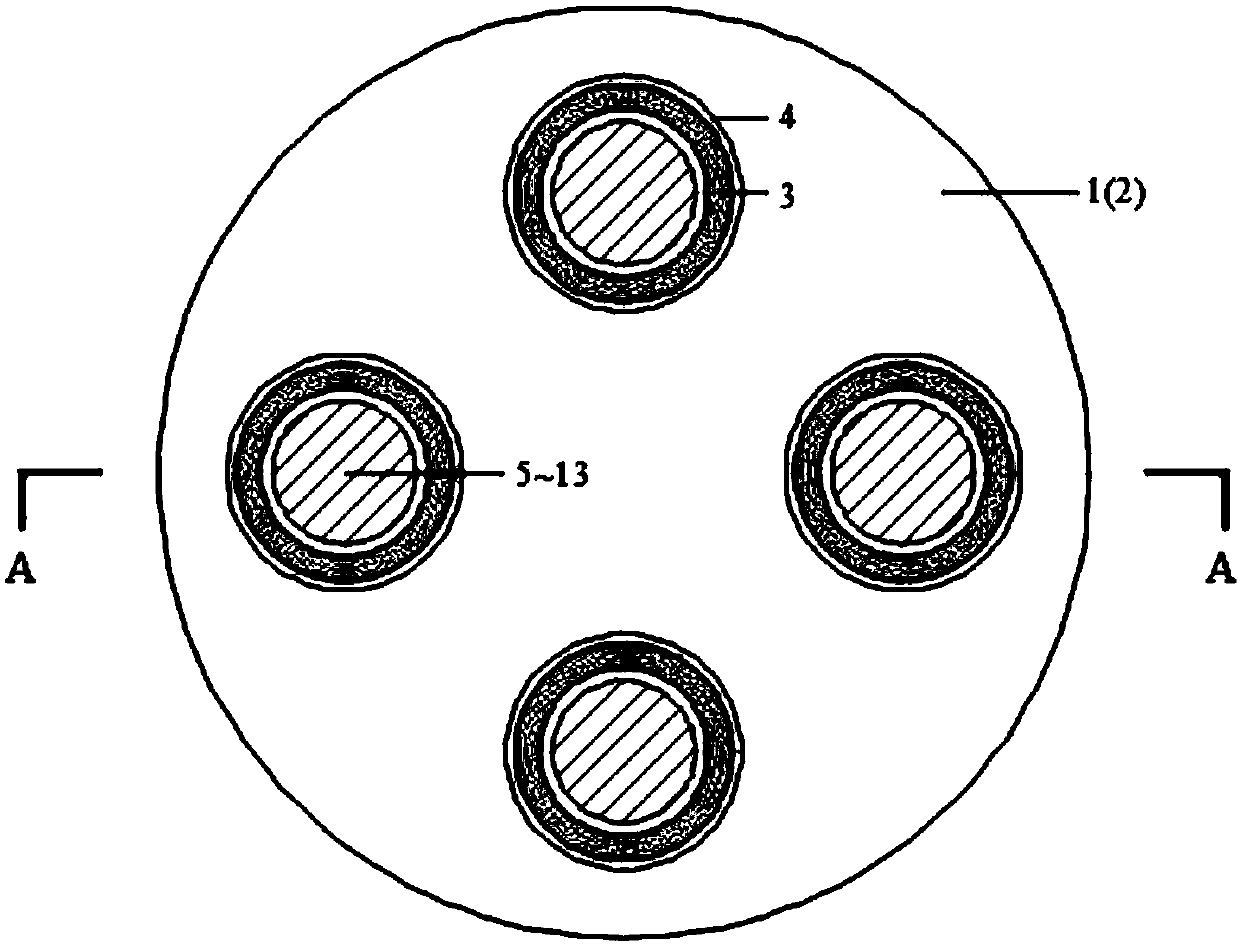

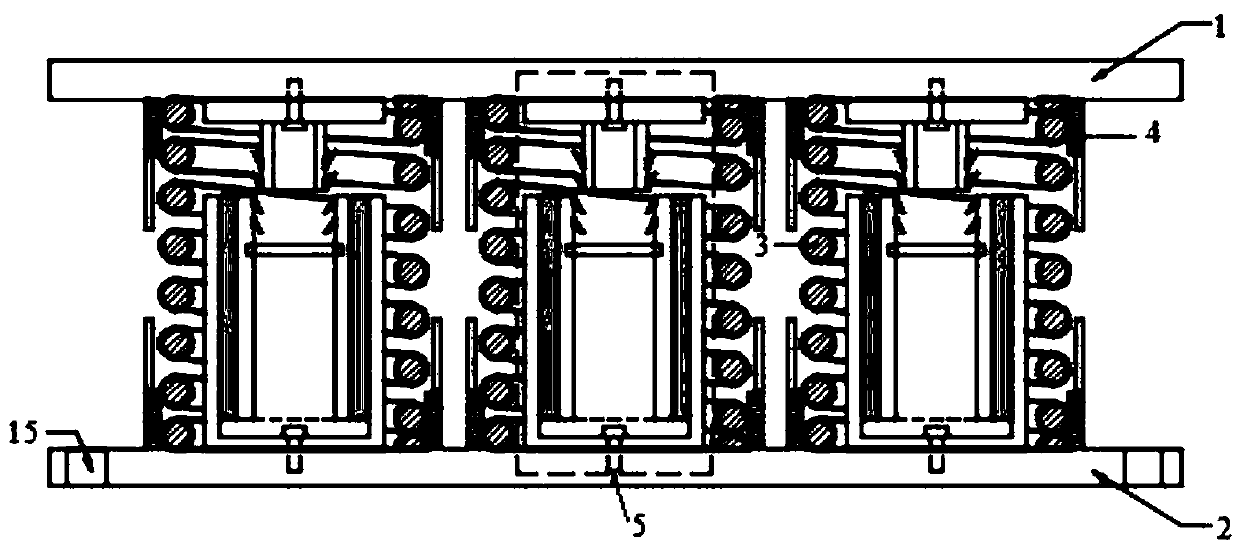

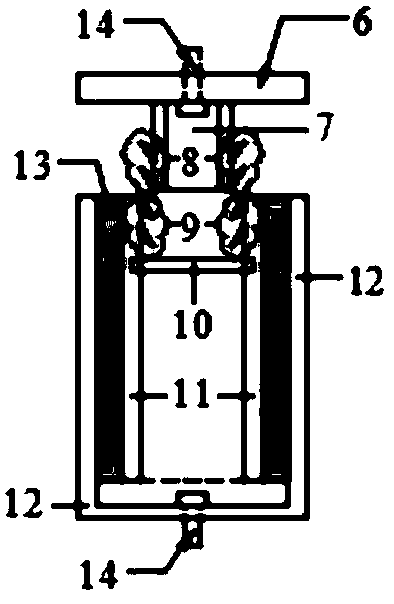

[0027] Embodiment: a kind of spring damping synergy isolating and damping / vibration device, such as figure 1 , 2 As shown, it includes upper and lower steel plates 1 and lower steel plates 2 corresponding to each other and arranged horizontally, and several groups of coil springs 3 and barbed viscoelastic cylinder dampers 5 evenly distributed between the upper and lower steel plates 1 and 2 .

[0028] The bottom surface of the upper steel plate 1 is evenly distributed with several upper threaded sleeves 4, and the top surface of the lower steel plate 2 is also evenly distributed with several lower threaded sleeves 4 corresponding to the positions of the upper threaded sleeves 4. The upper and lower threaded sleeves 4 Threads are provided on the inner peripheries near the ends of the upper and lower steel plates 1 and 2 respectively, and the inner diameter of the other end of the sleeve 4 is larger than the inner diameter of the threads, and there are no threads, which can inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com