Shear buckling prevention steel plate shear wall free of bearing gravity

A steel plate shear wall and steel plate wall technology, which is applied to walls, buildings, building components, etc., can solve the problems that the dead load and live load of the steel plate shear wall cannot be completely exempted, and the construction period is postponed, so as to achieve reasonable force, Easy processing and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

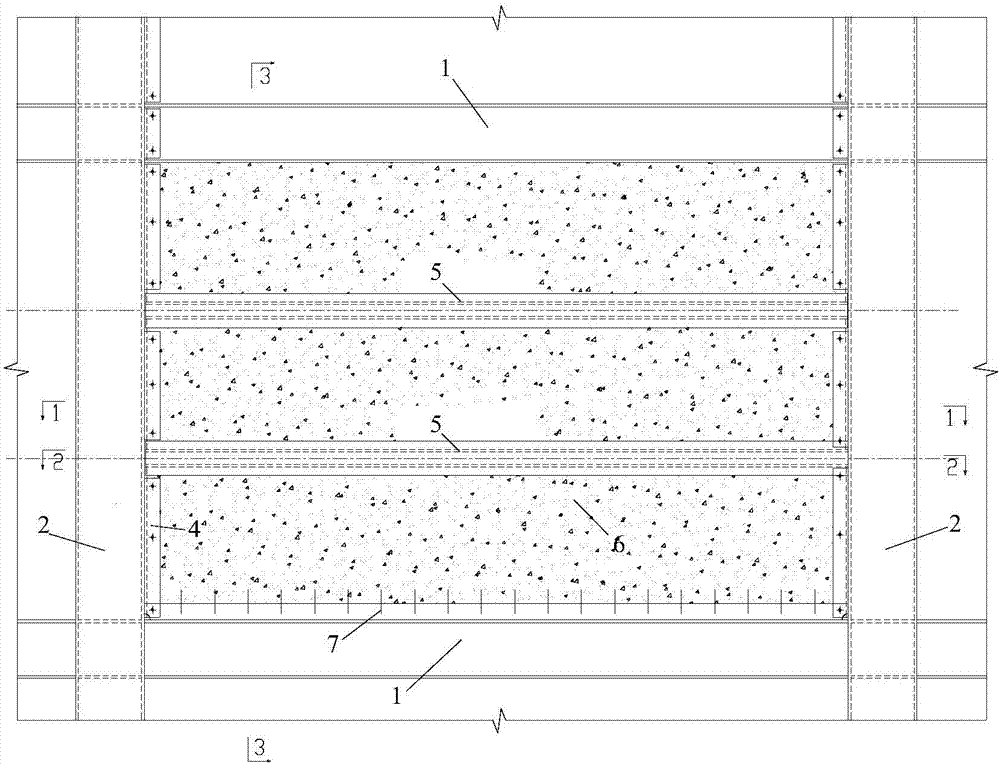

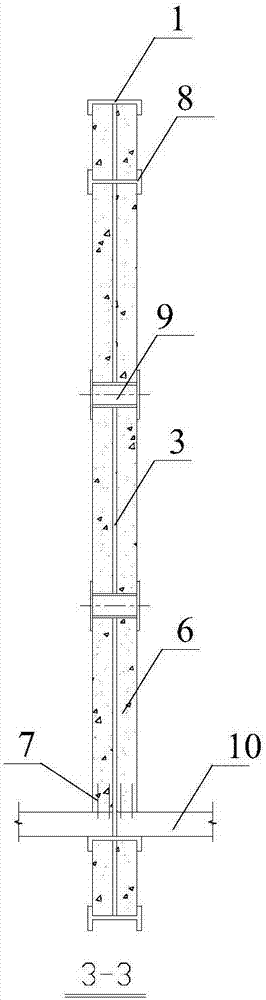

[0043] Such as figure 1 As shown, the embodiment includes a steel plate wall 3, a steel column 2, a steel beam 1, a horizontal stiffener 5 and a prefabricated concrete slab 6, the steel beam adopts an H-shaped steel beam, and the steel plate wall 3 is placed to form within the framework. The upper and lower sides of the steel plate wall 3 are welded to the steel beam 1, and the left and right sides of the steel plate wall 3 are fixedly connected to the steel column 2 through fishplates 4.

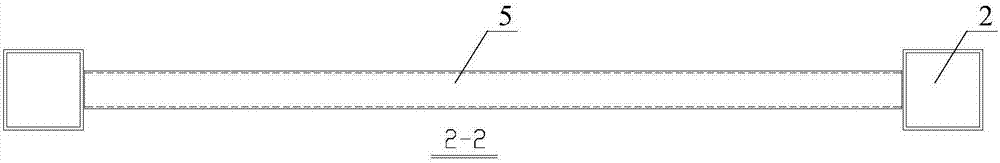

[0044] In the steel plate wall 3, horizontal stiffeners 5 are arranged along the horizontal direction of the steel plate wall. The upper and lower surfaces of the horizontal stiffeners 5 are welded to the steel plate wall 3, and the two ends of the horizontal stiffeners are not connected to the steel columns, such as image 3 shown.

[0045] The specific implementation includes three horizontal stiffeners 5, such as figure 2 As shown, the three horizontal stiffeners 5 are respectively a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com