Vibration damping fastener system for multi-layer pad

A technology of vibration-damping fasteners and backing plates, which is applied in the field of rail transit, can solve problems such as reduced stiffness, low acceptance, and restrictions, and achieve the effects of ensuring safety in use, improving line safety, and high vibration-damping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is described in conjunction with accompanying drawing and specific embodiment:

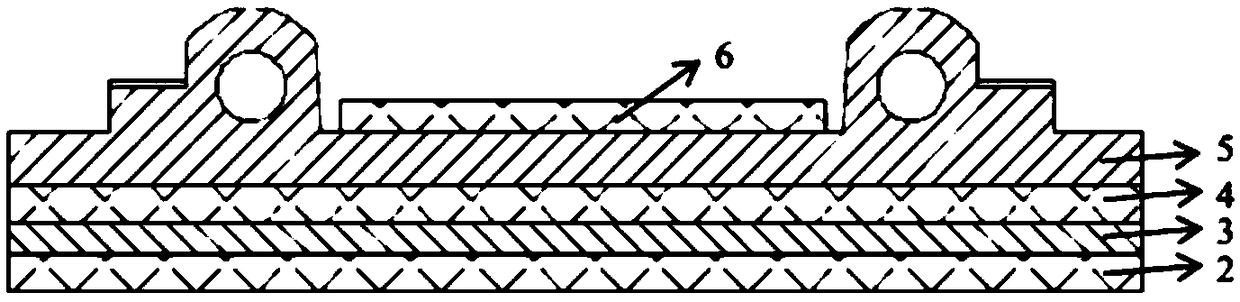

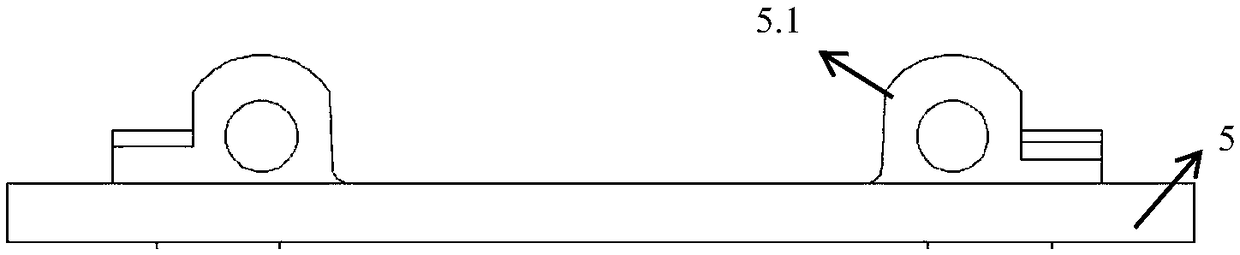

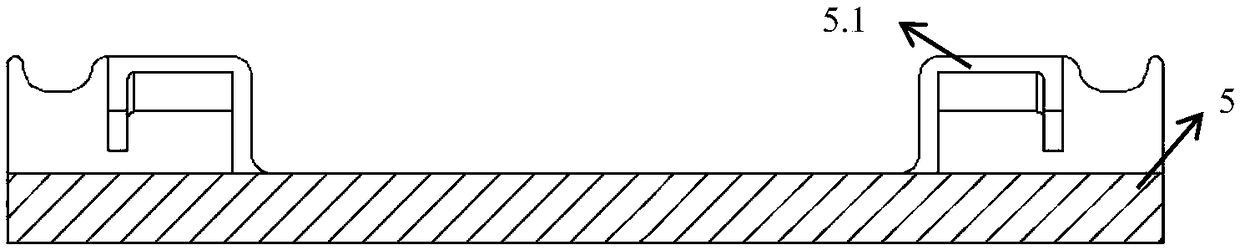

[0046] like figure 1 Shown, a kind of damping fastening system of multi-layer backing plate, the vibration-damping fastening system of described multi-layer backing plate comprises elastic layer and backing plate, and described elastic layer comprises elastic pad 6 under the rail, first elastic layer 4 and the second elastic layer 2; the backing plate includes a first backing plate 5 and a second backing plate 3. The elastic layer is made of rubber and polyurethane elastic materials; the backing plate can be produced by metal and non-metallic materials; the hardness and density of the material used for the backing plate are greater than the corresponding properties of the material used for the elastic layer. The under-rail elastic pad 6, the first backing plate 5, the first elastic layer 4, the second backing plate 3, and the second elastic layer 2 are adjacently arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com