Steel pipe connecting structure for compensating differential settlement and construction method

A technology for connecting structures and pipelines, applied in the direction of pipes/pipe joints/fittings, pipeline protection, pipeline damage/wear prevention, etc., can solve problems such as blocked pipelines, prevent pipeline deformation, ensure fatigue performance, reduce probability and investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

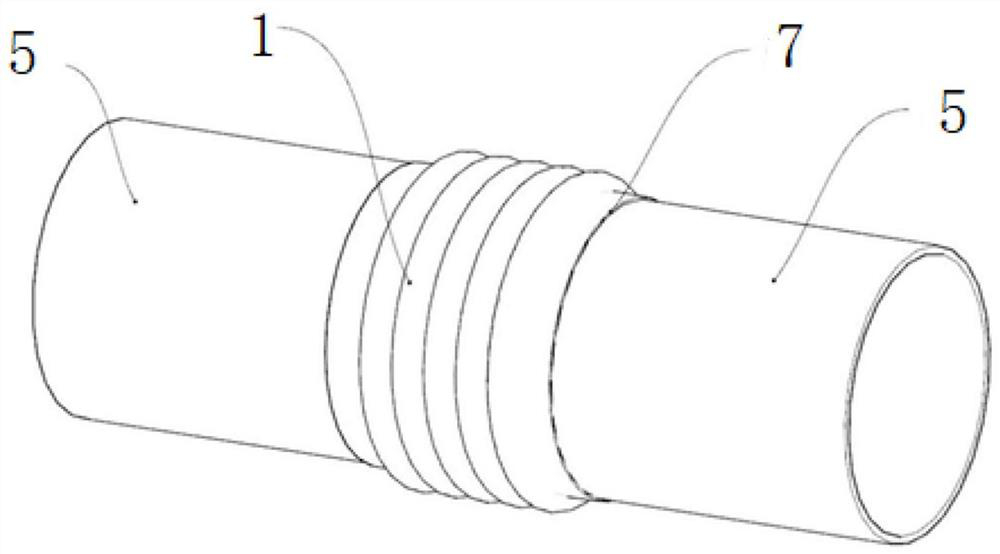

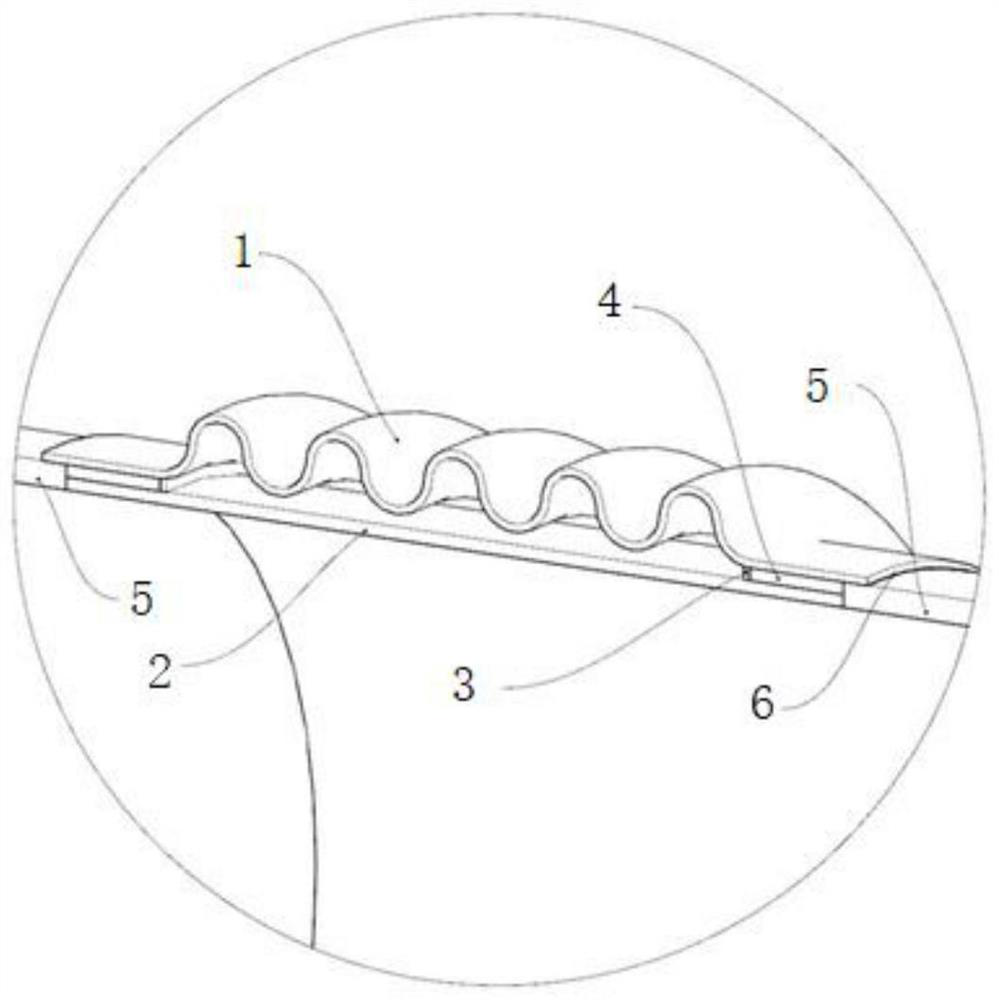

[0028] The embodiment of the present application provides a steel pipe connection structure that compensates for uneven settlement, such as figure 1 with 2 As shown, it includes steel pipes 5 at both ends and a steel corrugated pipe connected between the steel pipes 5 at both ends. The steel corrugated pipe is provided with a liner, and the liner is a flexible lining 2. The end of the lining pipe is bonded to the steel bellows through high-strength metal glue 4 . In the above-mentioned embodiment, the steel bellows and the inner liner are composed of a combined sleeve, wherein the steel bellows adopts C-shaped steel bellows 1, and the material is high-quality carbon steel with high elasticity and high strength. The selected steel bellows The pipe 1 compensator has the functions of compression resistance, bending resistance and corrosion resistance. It adopts the sleeve form of the flexible lining 2 and the bellows compensator to avoid the resistance and blockage of the inner ...

Embodiment 2

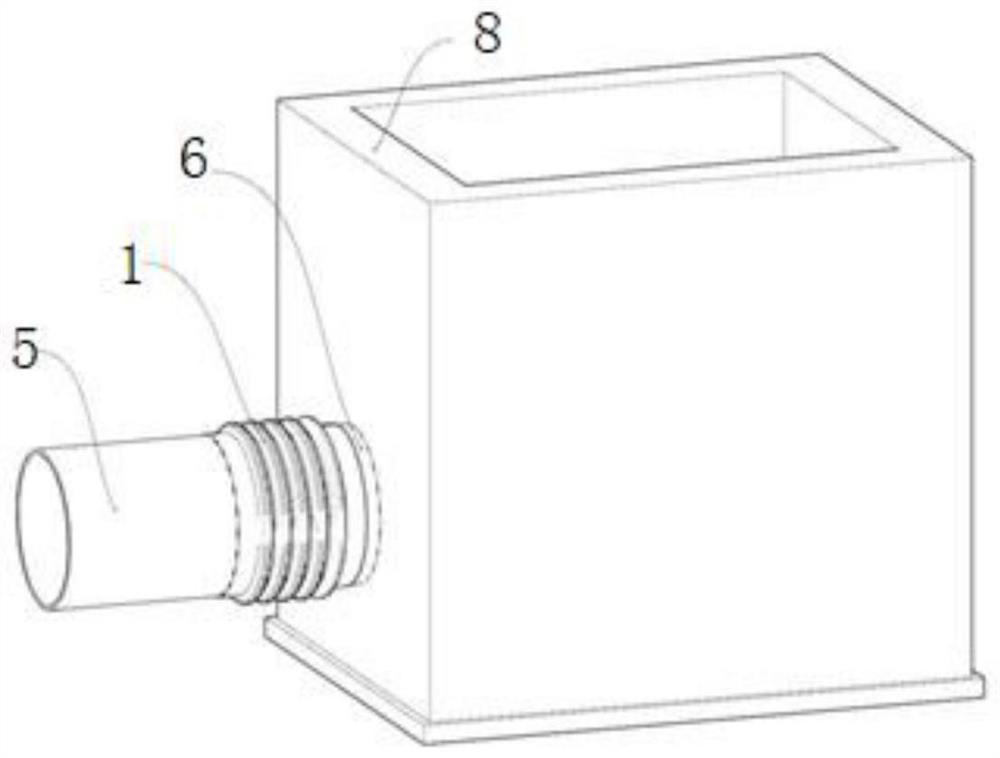

[0036] This embodiment provides a connection structure for steel pipes connected to well-shaped structures to resist uneven settlement, such as Figure 3-4 As shown, the difference from the above embodiment is that one end of the steel corrugated pipe is connected to the steel pipe, and the other end is connected to the well-shaped structure 8, wherein the embedded water-stop casing 6 is connected to the well-shaped structure 8 .

[0037] Its specific construction method is as follows:

[0038] Step 1: Prefabrication of the steel bellows combination device: combine the flexible lining 2 with the steel bellows in advance, apply high-strength metal glue 4 evenly on the contact surface and install the sealing ring 3 on the inner side to prevent liquid from leaking from the contact surface gap ;

[0039] Step 2: Pre-embed the water-stop casing 6 when making the well-shaped structure, and reserve a corrugated pipe placement point at the bottom of the foundation pit before the pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com