Process for flash welding medium control limit Mn content R350 HT steel rail with joint structure

A technology for R350HT and welded joints, which is applied in the field of flash welded joints of R350HT rails with limited Mn content, can solve the problems of increasing the content of martensite in the joints, and achieve the effect of simple control process and good promotion and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

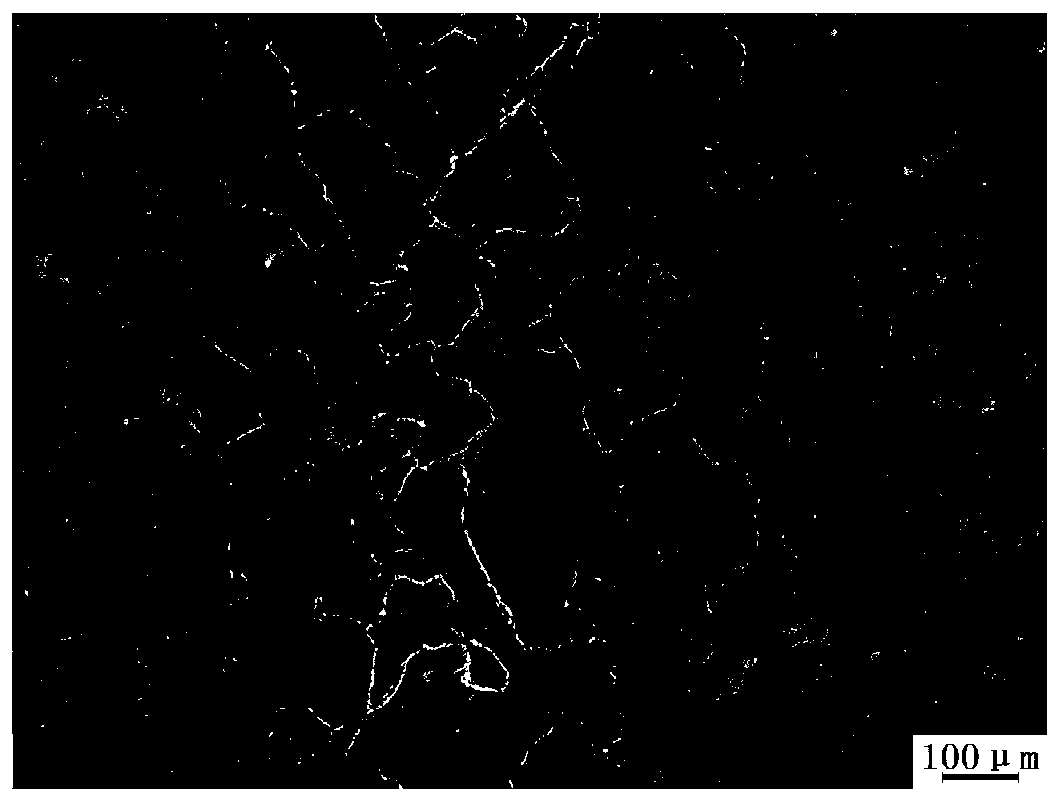

Image

Examples

Embodiment 1

[0033] Using the flash welding process with heat input of 6.5MJ and upsetting amount of 14.0mm, the European standard R350HT heat-treated steel rail with a mass fraction of Mn of 0.90% (C content is in the middle and lower limits, Si≤0.30wt%, Rm≥1175MPa, A ≥9%, tread hardness ≥350HB) for flash welding. After the flash welding is completed, first use an infrared thermometer to measure the temperature at the center of the weld seam on the road surface of the naturally cooled rail joint, and when the temperature drops to 515°C, immediately use an aluminosilicate fiber cotton insulation device with a thickness of ≥30mm Insulate the 200mm area on both sides of the joint fusion line; continue to monitor the joint temperature during this process, and remove the device when the temperature at the center of the welding seam on the driving surface is lower than 250°C, and finally place the joint in the air to cool naturally to room temperature .

[0034] According to EN 14587.2, the jo...

Embodiment 2

[0036] Using the flash welding process with heat input of 6.8MJ and upsetting amount of 14.7mm, the European standard R350HT heat-treated steel rail with a mass fraction of Mn of 0.98% (C content is in the middle and lower limits, Si≤0.30wt%, Rm≥1175MPa, A ≥9%, tread hardness ≥350HB) for flash welding. After the flash welding is completed, first use an infrared thermometer to measure the temperature at the center of the weld seam on the road surface of the naturally cooled rail joint. When the temperature drops to 545°C, immediately use an aluminosilicate fiber cotton insulation device with a thickness ≥ 30mm Insulate the 200mm area on both sides of the joint fusion line; continue to monitor the joint temperature during this process, and remove the device when the temperature at the center of the welding seam on the driving surface is lower than 250°C, and finally place the joint in the air to cool naturally to room temperature .

[0037] According to EN 14587.2, the joints o...

Embodiment 3

[0039] Using the flash welding process with heat input of 8.0MJ and upsetting amount of 15.0mm, the European standard R350HT heat-treated steel rail with a mass fraction of Mn of 1.10% (C content is in the middle and lower limits, Si≤0.30wt%, Rm≥1175MPa, A ≥9%, tread hardness ≥350HB) for flash welding. After the flash welding is completed, first use an infrared thermometer to measure the temperature at the center of the weld seam on the road surface of the naturally cooled rail joint. When the temperature drops to 530°C, immediately use an aluminosilicate fiber cotton heat insulation device with a thickness ≥ 30mm Insulate the 200mm area on both sides of the joint fusion line; continue to monitor the joint temperature during this process, and remove the device when the temperature at the center of the welding seam on the driving surface is lower than 250°C, and finally place the joint in the air to cool naturally to room temperature .

[0040] According to EN 14587.2, the joi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com