Prefabricated assembly type toughness combined bridge deck slab with cast-in-place wet joints and manufacturing method

A prefabricated assembly and wet joint technology, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problem of increasing repair and maintenance costs of bridge structures, affecting the corrosion resistance and durability of bridge decks, and making construction quality and precision difficult Guarantee and other issues, to achieve the effect of ensuring the shear connection effect, avoiding welding work, and convenient and efficient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

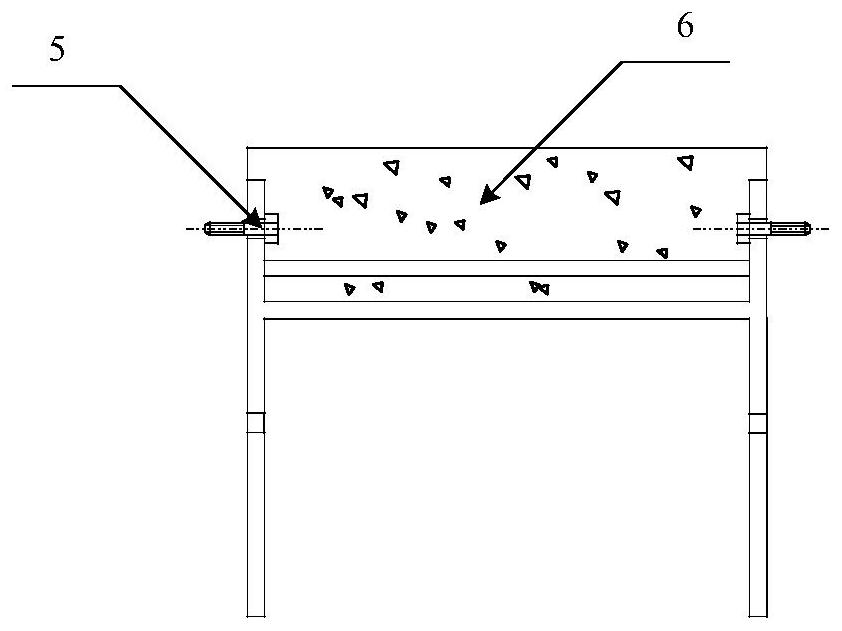

[0039] Such as Figure 3-4 As shown, a prefabricated assembled ductile composite bridge deck with cast-in-place wet joints includes the following components: steel composite prefabricated parts, prefabricated connectors, high-strength bolts 5, and cast-in-place ultra-high toughness concrete 7.

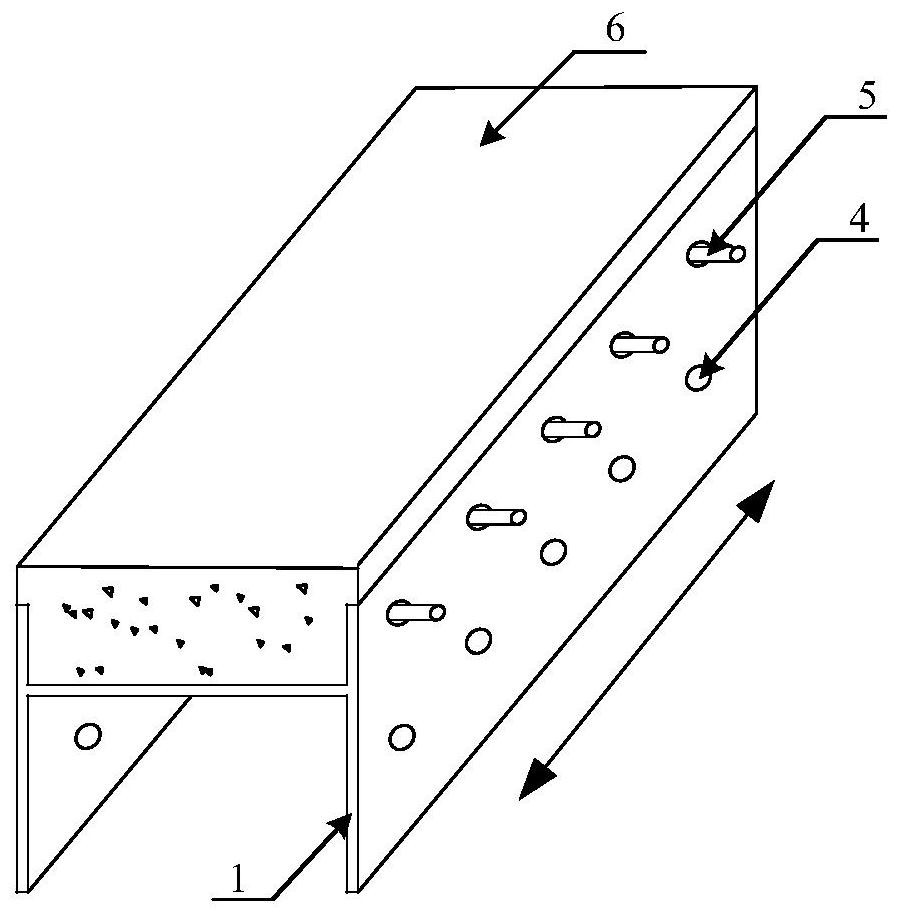

[0040] Such as figure 1 As shown, the combined prefabricated steel section includes wide hot-rolled H-shaped steel 1, round steel bar 3, high-strength bolts 5, and ultra-high toughness concrete 6; bolt holes 4 are opened on the flange of wide hot-rolled H-shaped steel 1, and the upper flank The transverse round steel bar 3 is welded on the edge plate, and after the high-strength bolt 5 screw is pre-embedded in the upper bolt hole 4, the ultra-high toughness concrete 6 is poured to form a prefabricated section steel combination.

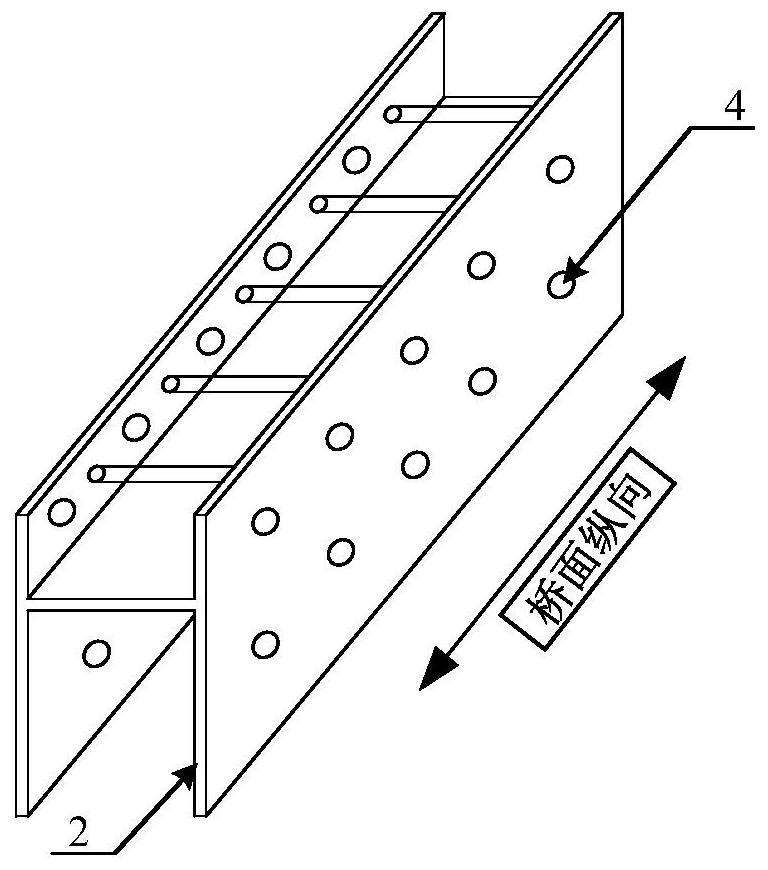

[0041] Such as figure 2 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com