Small Ultrasonic High Speed Drilling CNC Machine Tool

A CNC machine tool, ultrasonic technology, applied to the parts of boring machine/drilling machine, boring/drilling, large fixed members, etc., can solve the problems of limiting high-performance engines, nano-satellite micro-unmanned platforms, etc., to improve processing consistency , high dimensional accuracy, and the effect of shortening processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further elaborated below in conjunction with the accompanying drawings.

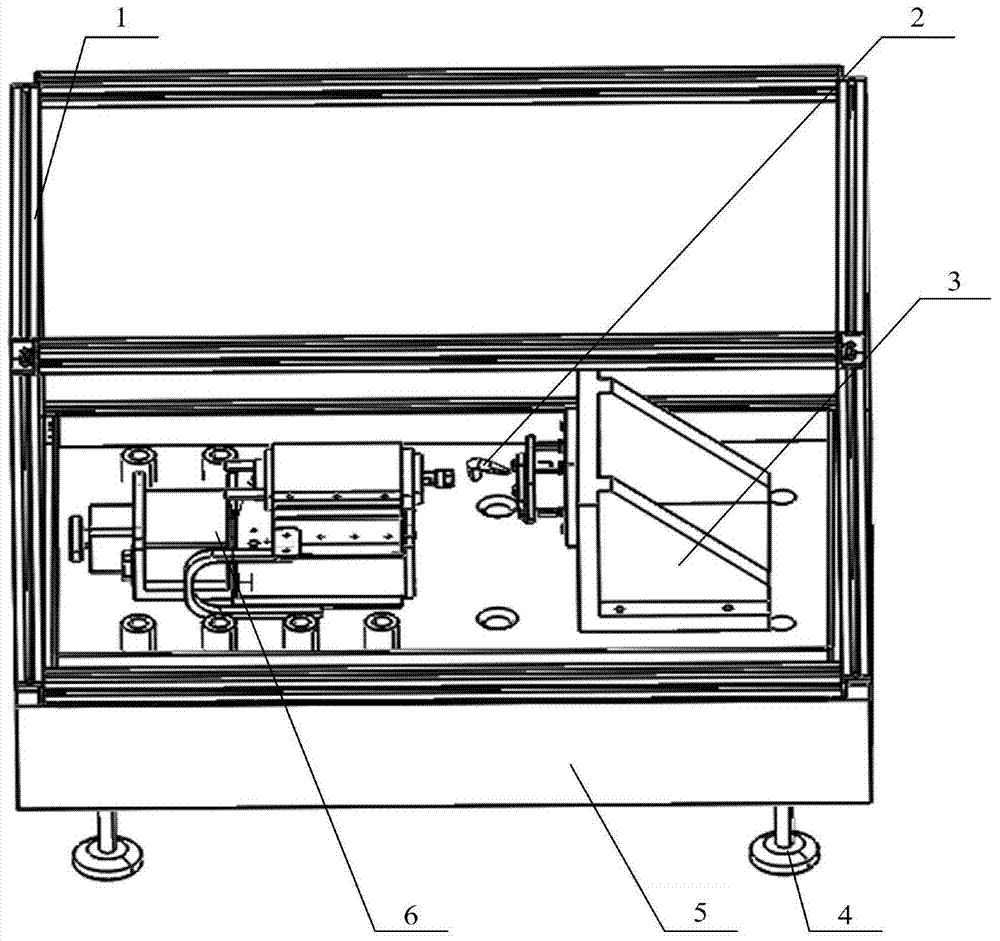

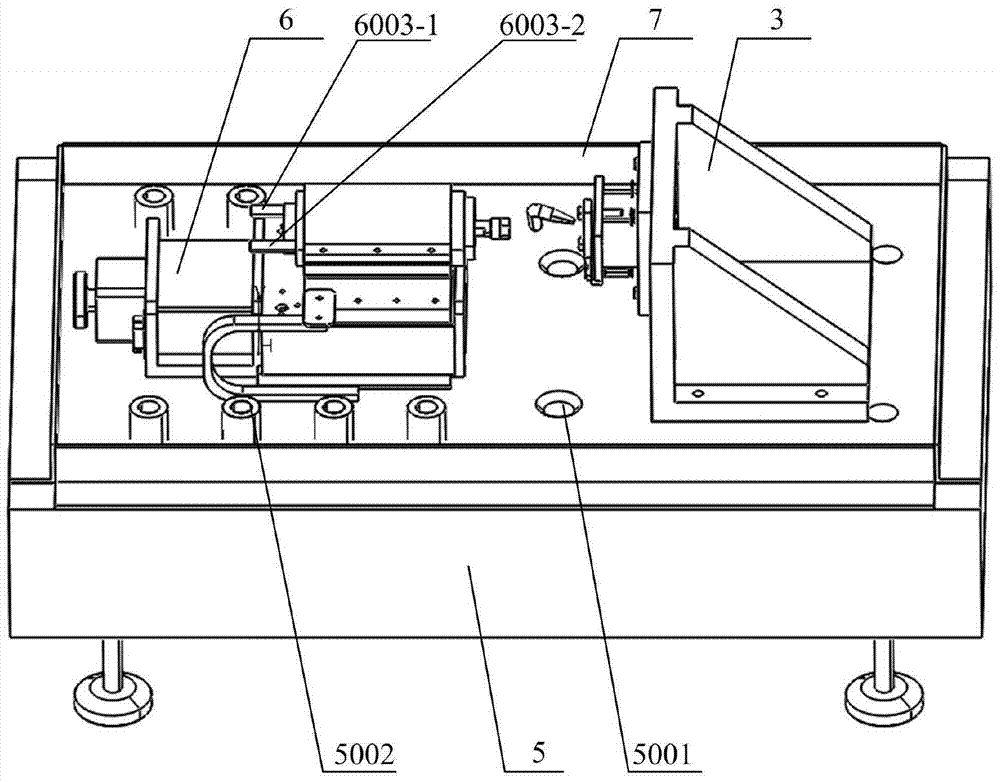

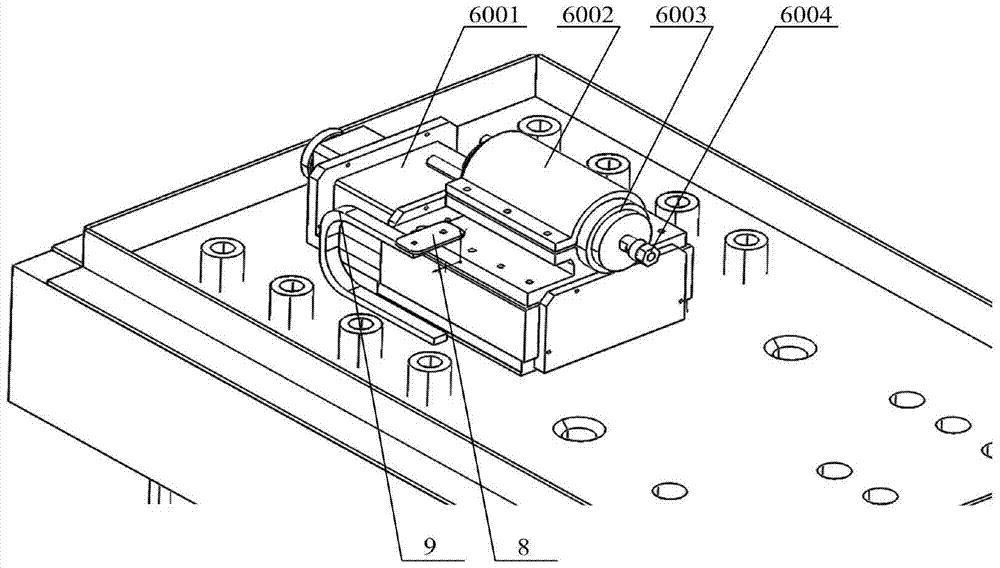

[0030] See attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 And attached Figure 12 , the small ultrasonic high-speed drilling CNC machine tool of the present invention includes a vibration clamping system 3, a drilling system 6, a cooling system 2, a protective cover 1, a marble platform 5, an adjustment foot 4 and a triangular aluminum 7;

[0031] Four pieces of triangular aluminum 7 are respectively glued on the four edges of the marble platform 5, the edge of each piece of triangular aluminum 7 is aligned with the edge of the marble platform 5, and the intersection of every two pieces of triangular aluminum 7 is glued together; four adjustment feet 4 respectively symmetrically fixedly connected to the four corners at the bottom of the marble platform 5;

[0032] The vibration clamping system 3 is fixedly connected to one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com