Five-axis numerical control machine tool

A technology for CNC machine tools and machine beds, which is applied to metal processing mechanical parts, large fixed members, driving devices, etc., can solve the problems of poor machine tool spindle rigidity and low machining accuracy, and achieves lower machine tool costs, high machining efficiency, and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

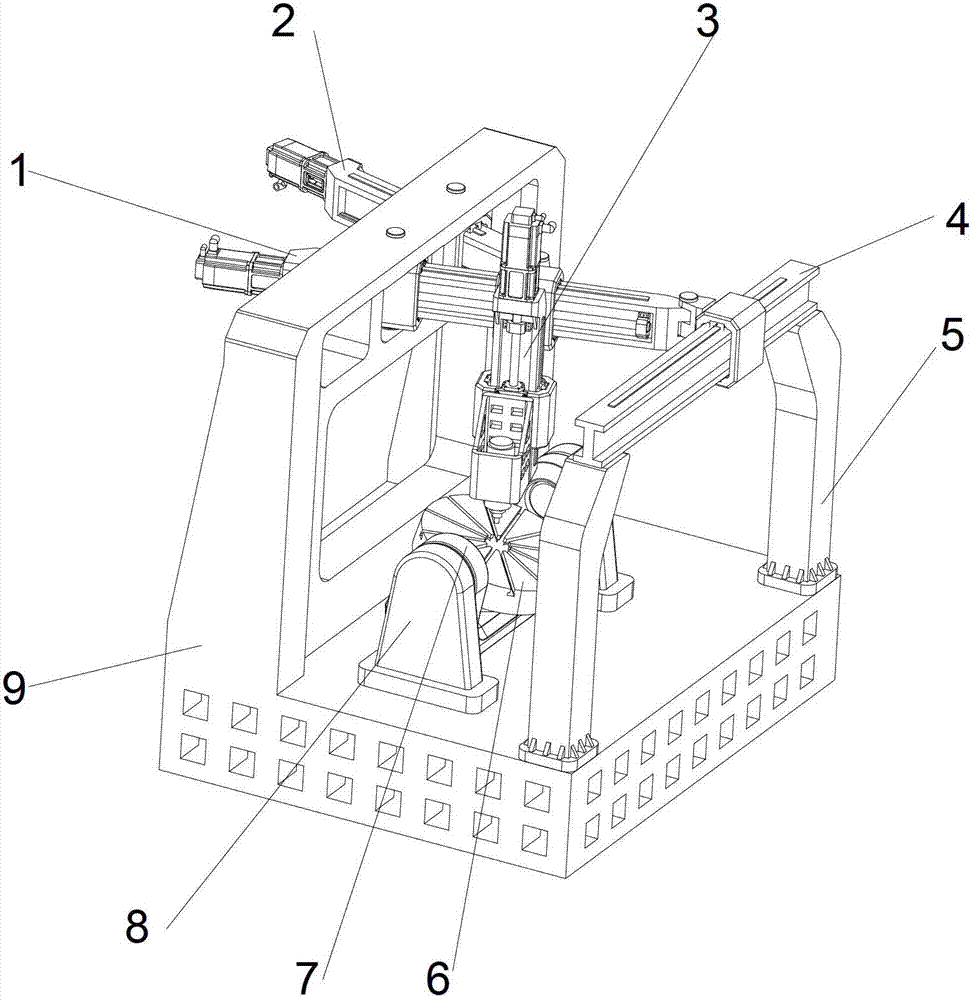

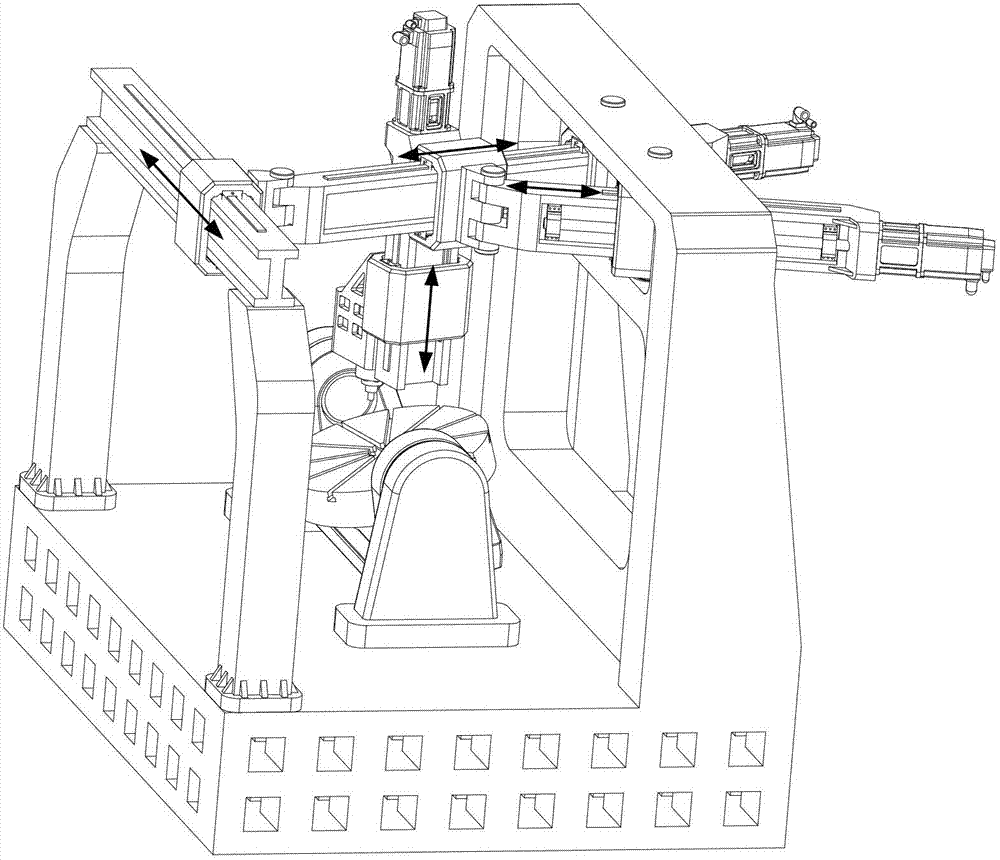

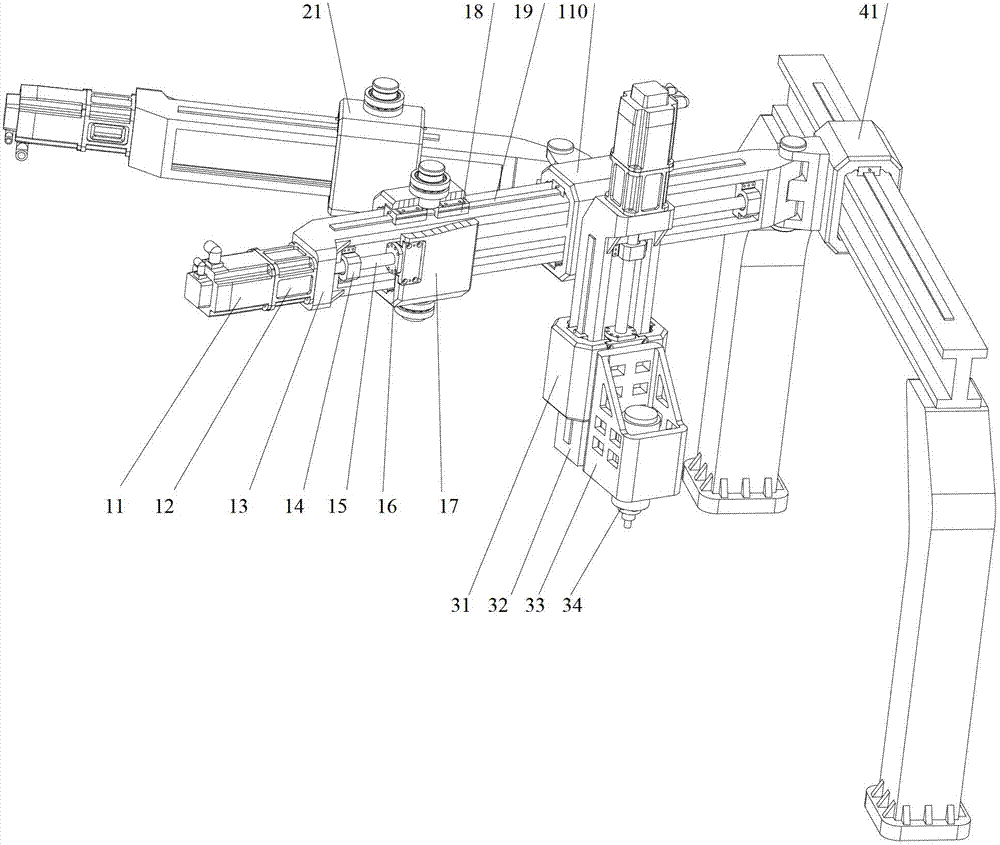

[0017] Please refer to Figure 1(a) and Figure 1(b), a five-axis CNC machine tool, including a bed 9, a cradle-type workbench, a first branch chain 1, a second branch chain 2, a third branch chain 3, and a column 5. Crossbeam 4, spindle frame 33 and electric spindle 34; the column 5 is fixed on the bed 9, and the two columns 5 are supported with the beam 4; The support seat 8 on the bed 9, the U-shaped cradle 7 and the rotary table 6, the center of the U-shaped cradle 7 is provided with the rotary table 6 connected to it through a rotating pair, and the U-shaped The cradle 7 is connected to the support base 8 through a rotating pair, and both the rotary table 6 and the U-shaped cradle 7 are provided with driving devices. The cradle-type workb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com