Integrated DC brushless limited angle torque motor rotor magnetic steel enclosing structure and method

A DC brushless, limited angle of rotation technology, applied in the direction of magnetic circuit shape/style/structure, manufacturing motor generators, manufacturing stator/rotor body, etc., can solve problems such as unavoidable bumps, affecting motor applications, and increasing motor weight , to achieve high rotor end face size and shape accuracy, easy processing and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

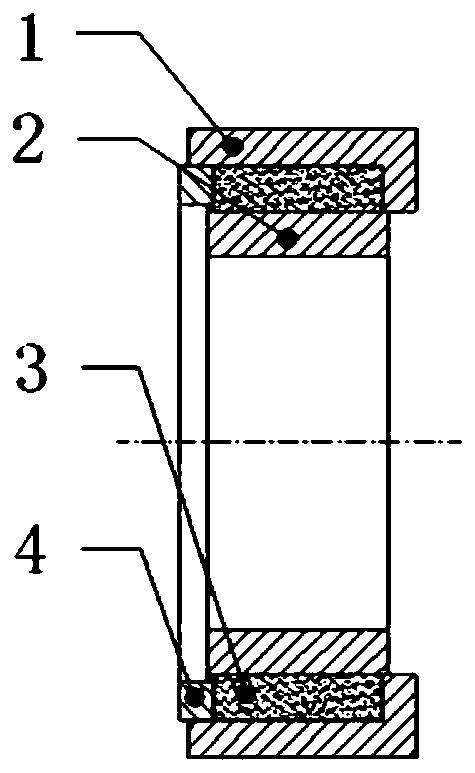

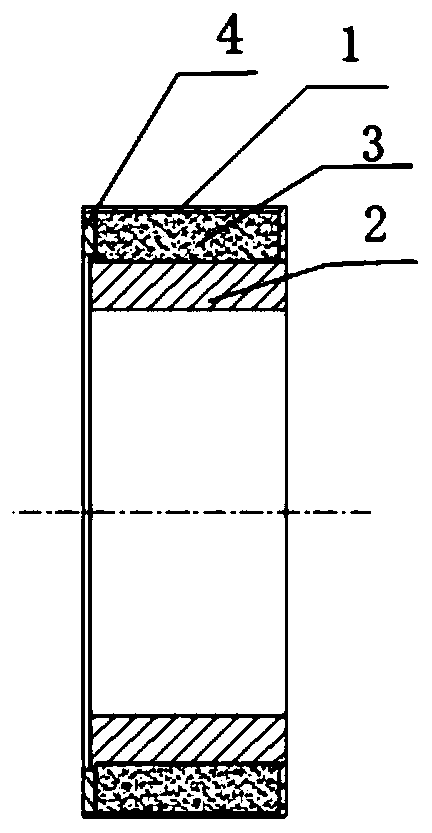

[0023] A self-contained DC brushless limited-angle torque motor rotor magnetic steel closed structure, please refer to Figure 1-2 , including rotor magnetic steel 3 and rotor iron core 2, and its invention points are:

[0024] It also includes a protective cover 1 and an end face gland 4. The protective cover is made of light non-magnetic material, preferably aluminum alloy or titanium alloy, but not limited to these two materials. The protective cover is a gyratory structure whose busbar is "L" shaped. The end gland is made of light non-magnetic material, preferably but not limited to aluminum alloy. The end gland is a ring structure with a rectangular cross section. The inner peripheral surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com