High-vanadium round wire tendon rope clamp as well as manufacturing process and design method thereof

A processing technology and technology of round steel wire, which is applied in the direction of construction and building structure, can solve the problems of poor anticorrosion performance of structures, affecting the appearance of cable clamp nodes, and increasing the number of high-strength bolts, etc., so as to shorten the production period and achieve reasonable force. Avoid complex effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

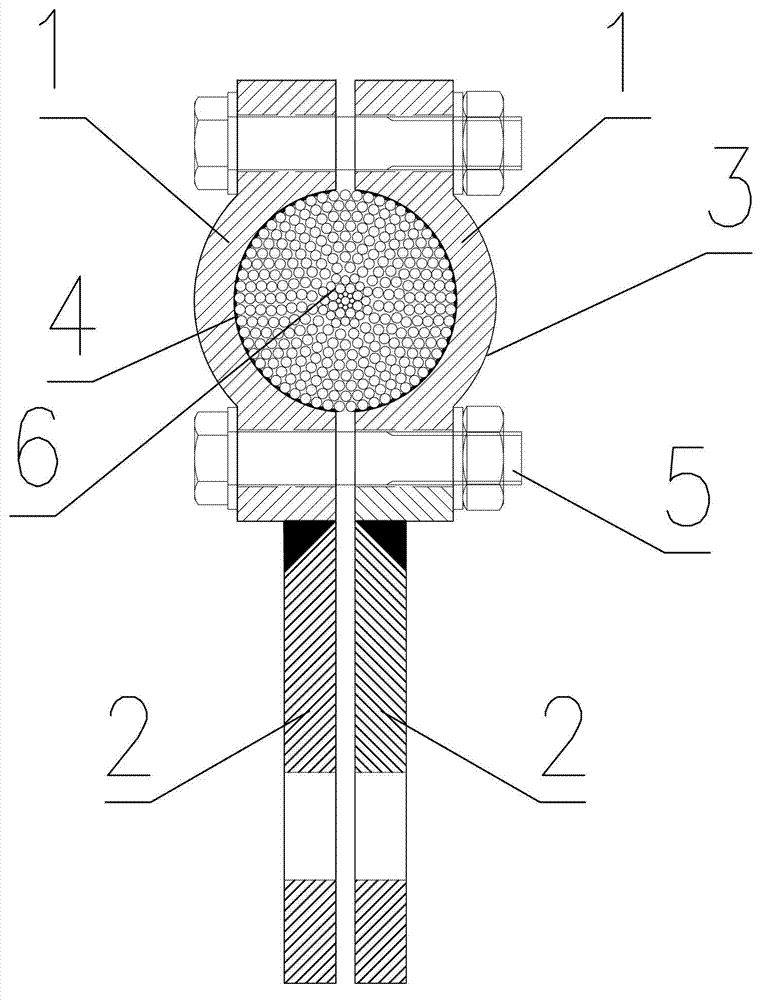

[0054] combined with Figure 1-6 , the preferred embodiment 1 of the present invention will be described in further detail.

[0055] The diameter of the high-vanadium round steel wire rope body 6 used in this embodiment is 100mm, which is the first large-diameter high-vanadium cable used in China. The high-vanadium round steel wire cable clamp includes a cable clamp body 1, a connecting lug plate 2, an anti-corrosion zinc layer 3, an anti-skid metal layer 4 and high-strength bolts 5.

[0056] The cable clip body 1 is mainly divided into a curved section 9 and a straight section 8, and a cable groove 11 is opened in the inside of the curved section 9, and the arc radius of the cable groove 11 is the same as the outer diameter of the cable body 6. Offer high-strength bolt holes 10 in the straight section 8 of the cable clamp body 1 . The inner surfaces of two symmetrically shaped cable clip bodies 1 are placed opposite each other, and the cable grooves 11 are fastened together...

Embodiment 2

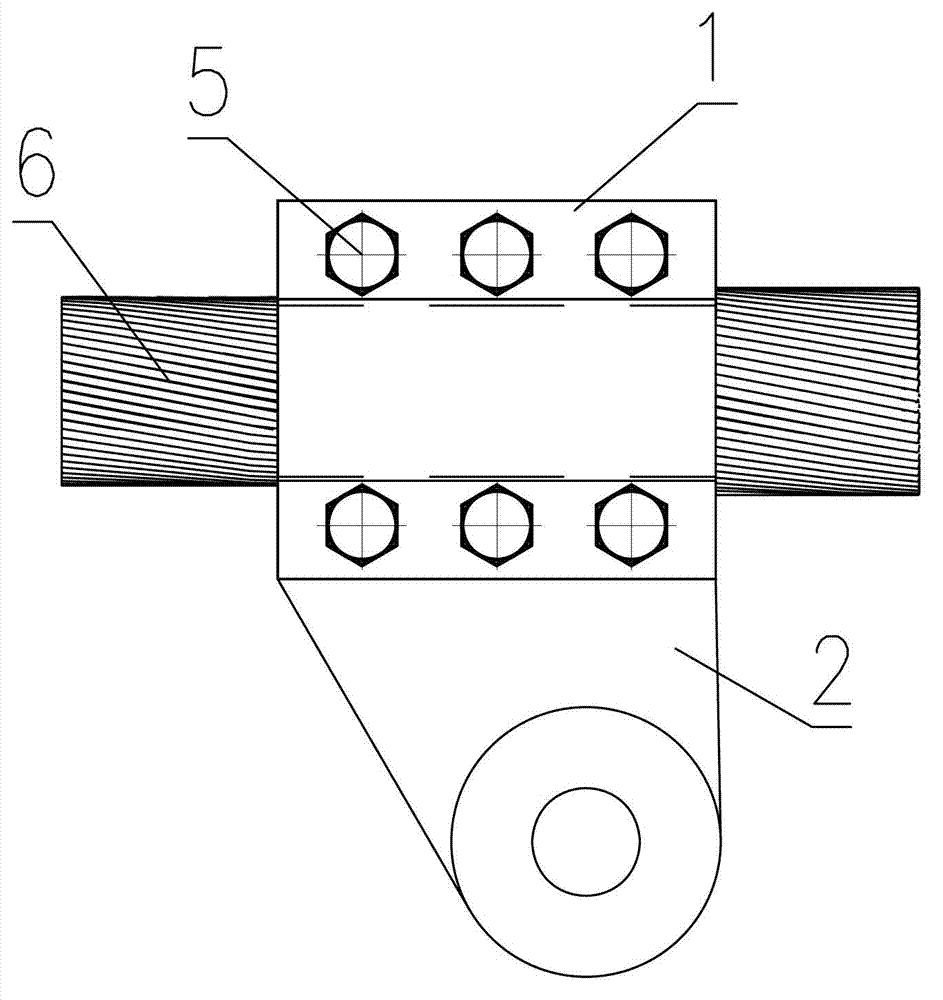

[0080] As a transformation of Embodiment 1 of the present invention, see Figure 7 , the welding position of the connecting ear plate 2 on the cable clamp body 1 has been changed, so that it can be connected with tension (compression) rods of different structures. The rest of the working principles are the same.

Embodiment 3

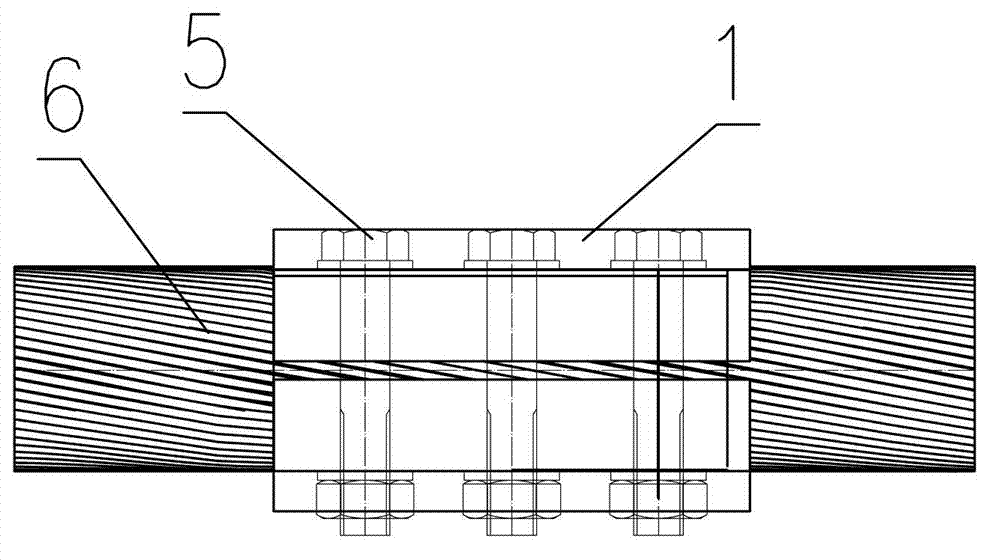

[0082] As another transformation of Embodiment 1 of the present invention, such as Figure 8 , the shape of the curved section 9 of the cable clip body 1 is machined into a straight section 13, the machining difficulty of the cable clip body 1 is reduced, and the production cost is reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com