Scaffold unloading steel wire rope setting method

A wire rope and scaffolding technology, which is applied in the setting field of scaffolding unloading wire ropes, can solve problems such as potential safety hazards, and achieve the effects of high safety, clear force, and simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

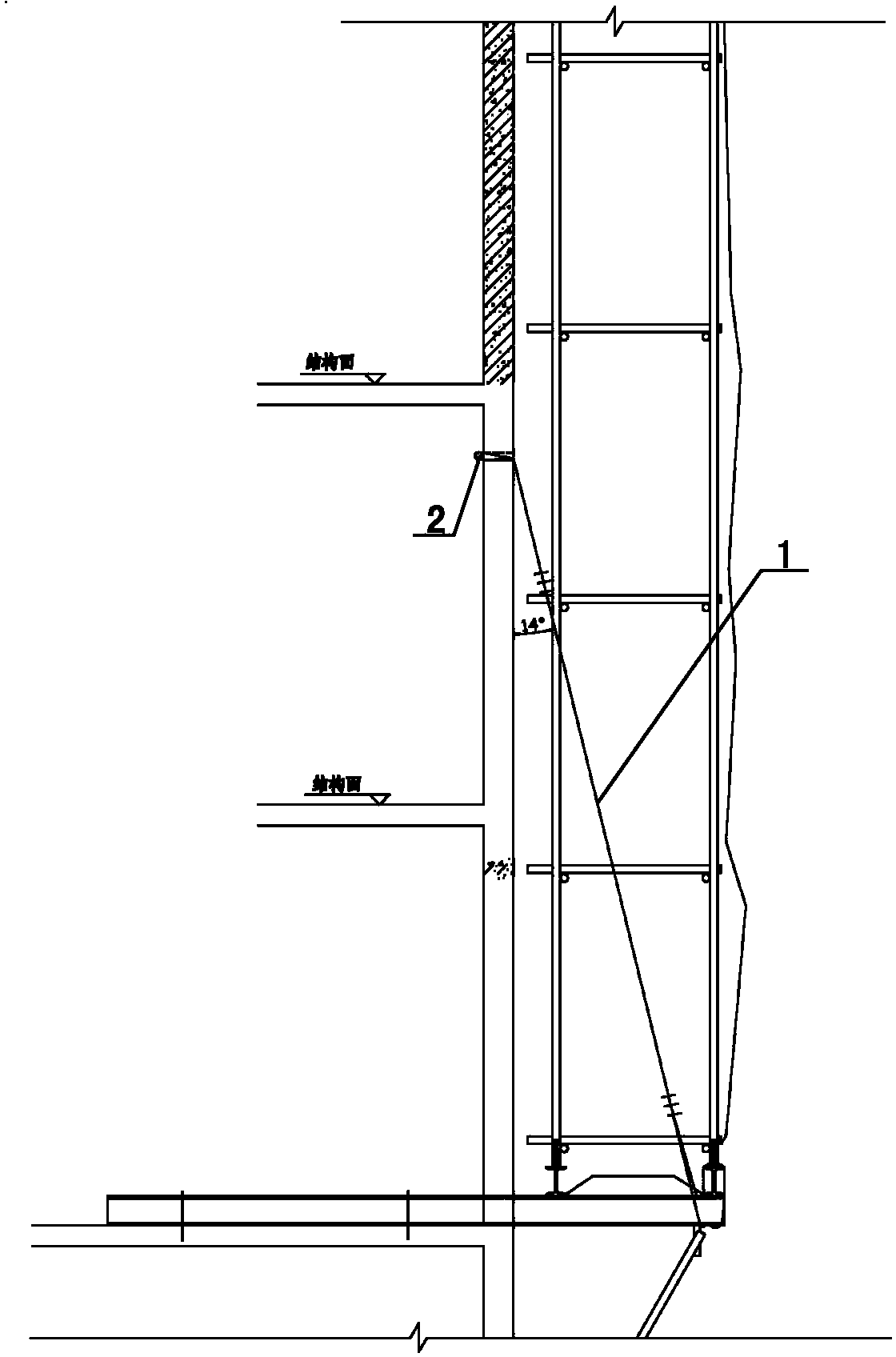

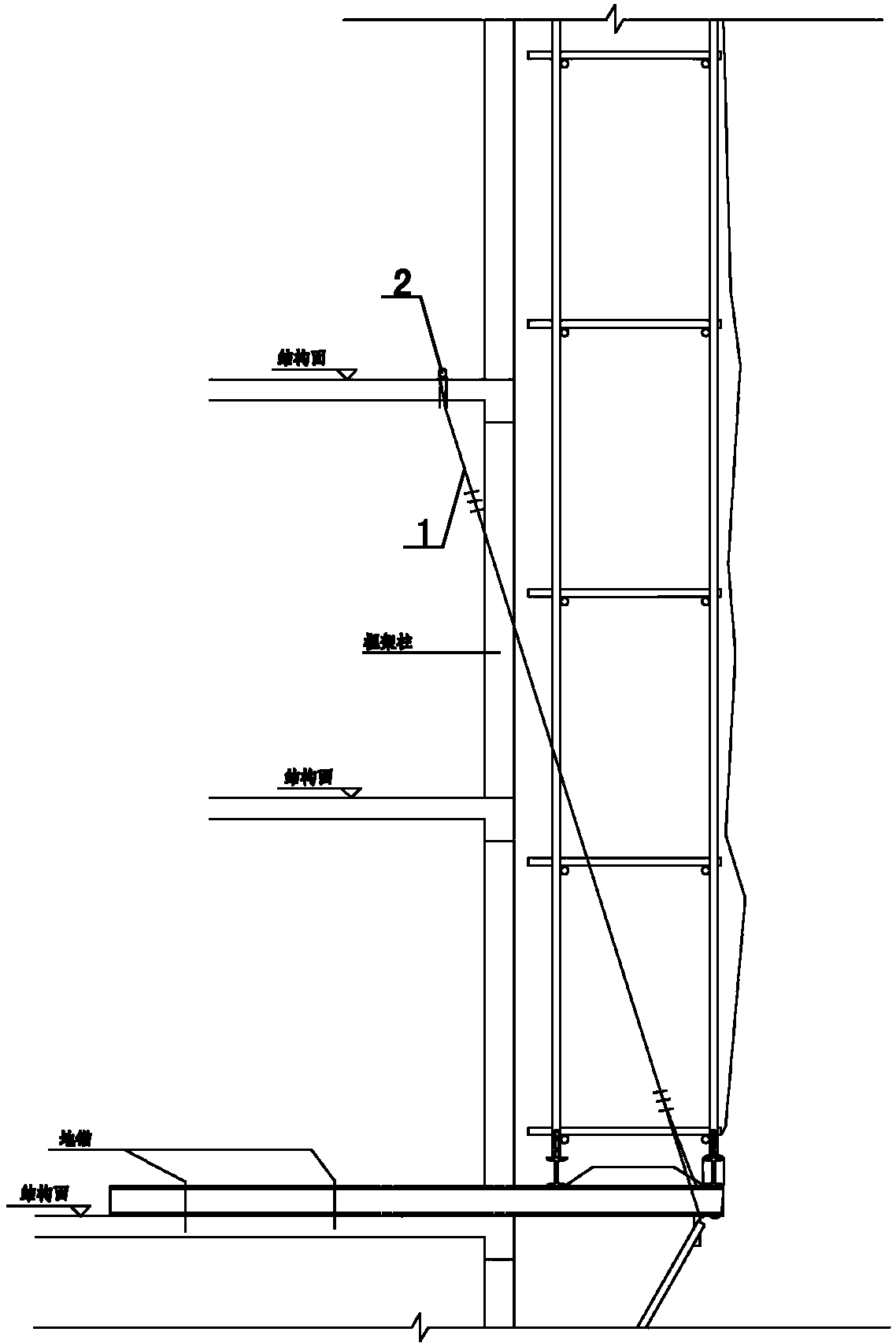

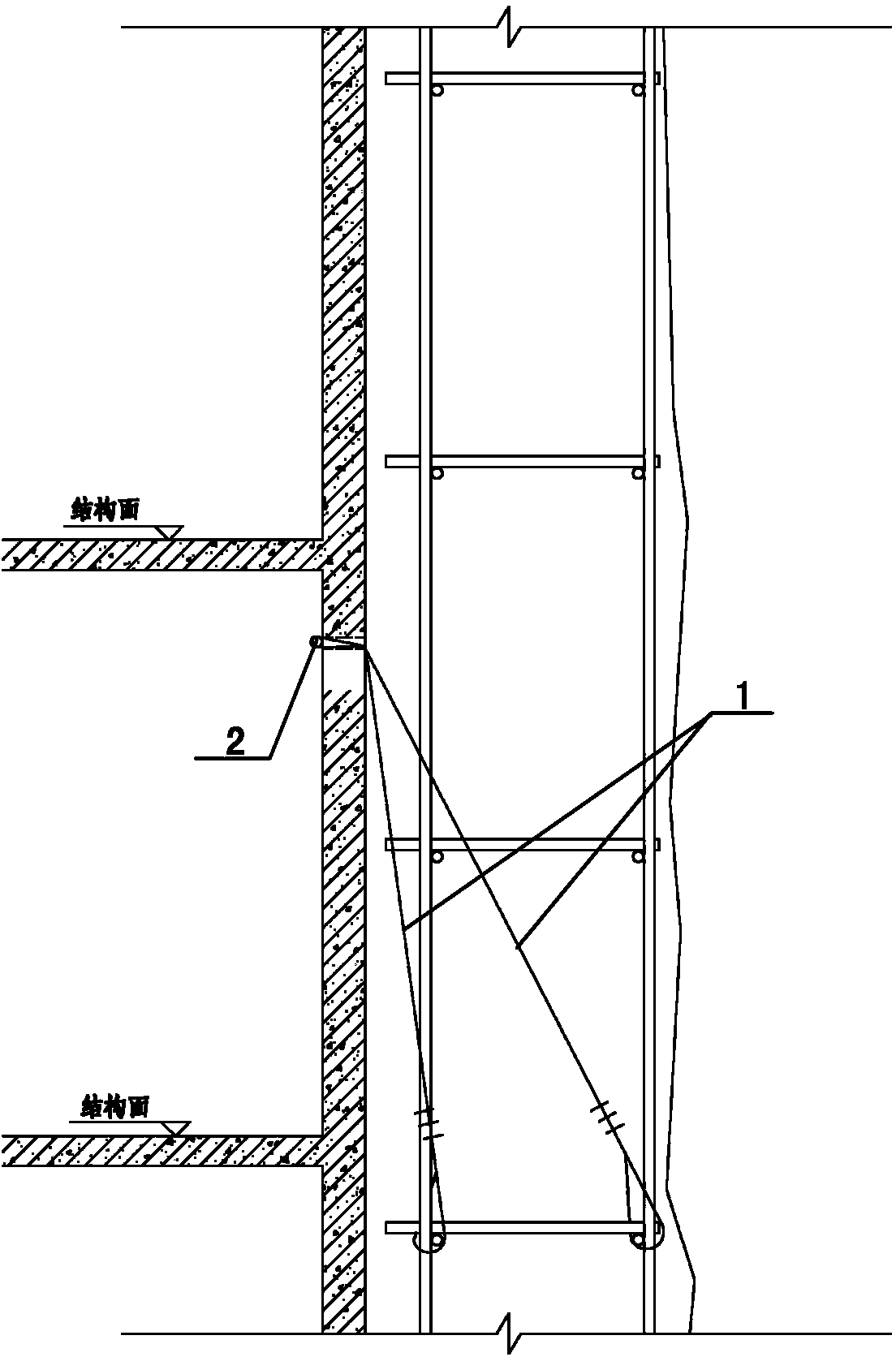

[0016] see Figure 1-6 Shown: Scaffold unloading steel wire rope setting method, unloading steel wire rope is set at the whole or partial corner of the scaffold, wherein, the steel wire rope is set at the bottom of the cantilevered scaffold and the middle layer of the frame body or the circumference of the floor frame body layer to unload the scaffold, unloading The steel wire rope 1 is fixedly connected to the main body of the structure by using the structural connecting beam through the beam bolt hole or the perforation reserved on the roof or wall at the corresponding position where the unloading steel wire rope is located. The unloading steel wire rope is 6×19 Ф12.5 steel wire rope, one end is connected to the main node where the scaffold pole and the cross bar intersect, and the other end is connected to the main structure; for the bottom of the cantilevered scaffold, the unloading steel wire rope is 6×19 (a ) Φ17.5 steel wire rope, hanging on the steel beam at the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com