Hollow high-bearing high-maneuverability spacecraft configuration

A spacecraft and configuration technology, applied in the direction of motor vehicles, aerospace vehicles, spacecraft propulsion system devices, etc., can solve the problems of limited expansion capacity of propellant carrying capacity, unsatisfactory length, large volume, etc., to achieve Strong task adaptability and expandability, strong task adaptability and expandability, and the effect of reducing the overall height and the height of the center of mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

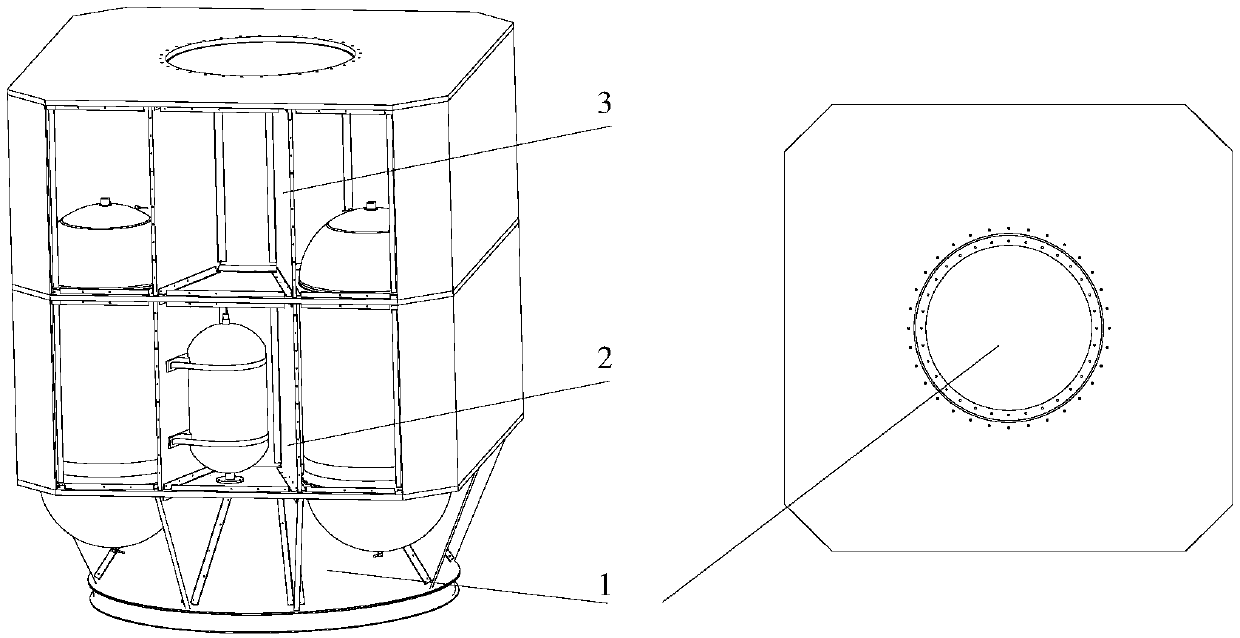

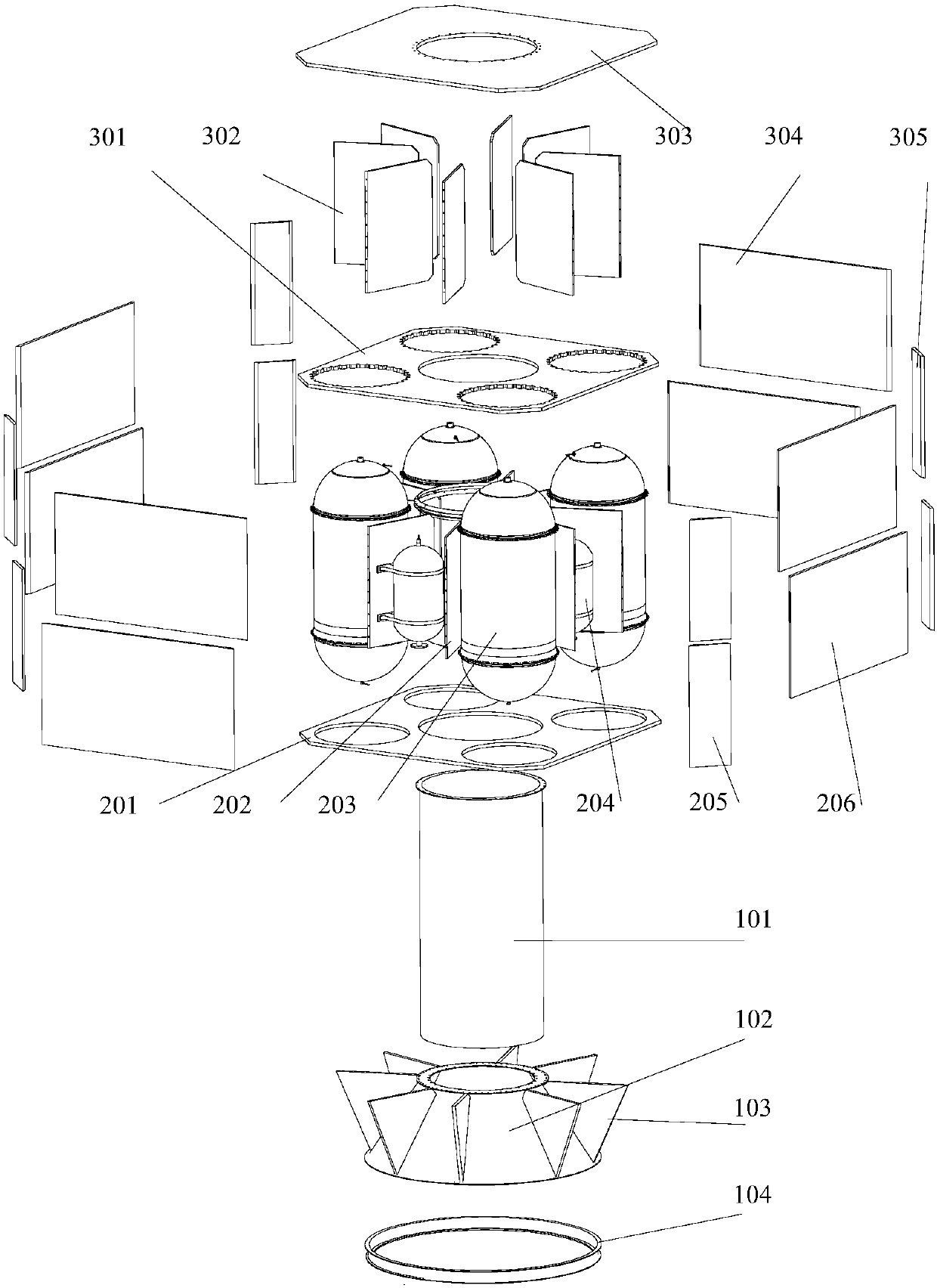

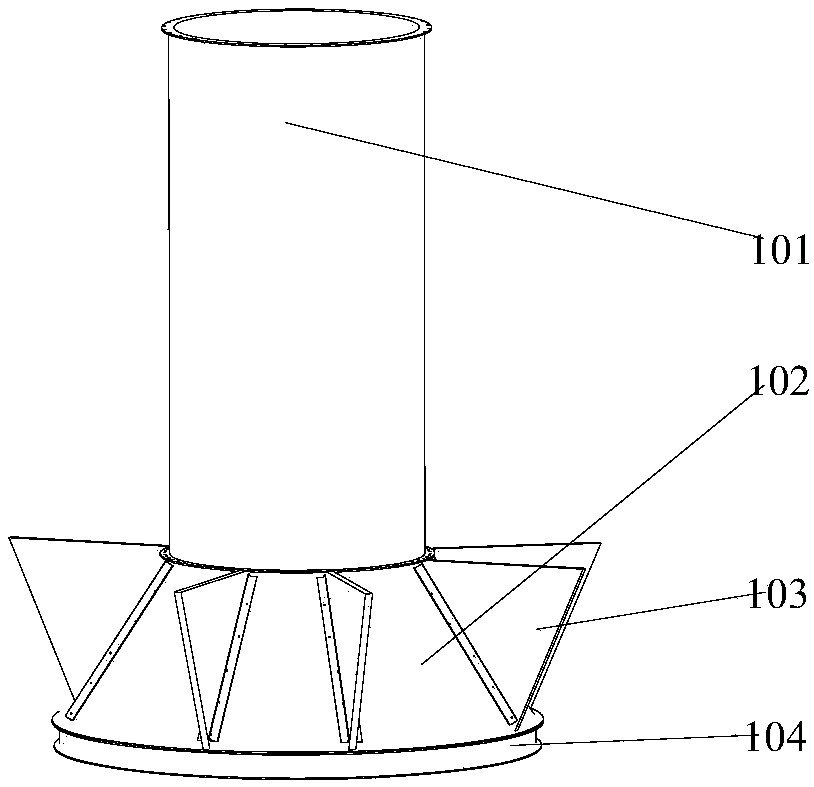

[0037] refer to figure 1 , figure 1 It is a schematic diagram of the outline structure of the hollow large-carrying and strong-maneuvering spacecraft configuration of the present invention, and the spacecraft is composed of a payload cabin 1 , a propulsion cabin 2 and an instrument cabin 3 . The load compartment 1 is located at the central axis of the spacecraft. The load compartment 1 passes through the central axis of the propulsion compartment 2 and the instrument compartment 3. The interior of the load compartment 1 is a cylindrical space with front and rear openings, which runs through the aerospace The entire vehicle is used to carry large space loads that need to be arranged in the middle of the spacecraft; the propulsion cabin 2 is located outside the load cabin 1 , and the instrument cabin 3 is located above the propulsion cabin 2 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com