High-efficiency and high-precision fixture of aircraft undercarriage bracket and clamping method thereof

An aircraft landing gear and high-efficiency technology, which is applied in the field of mechanical fixtures, can solve the problems of high workpiece hardness, high processing difficulty, low processing efficiency, etc., and achieves the effects of high positioning accuracy, convenient operation, and reliable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to illustrate the embodiments of the present application or the technical solutions in the prior art more clearly, the embodiments will be briefly introduced below.

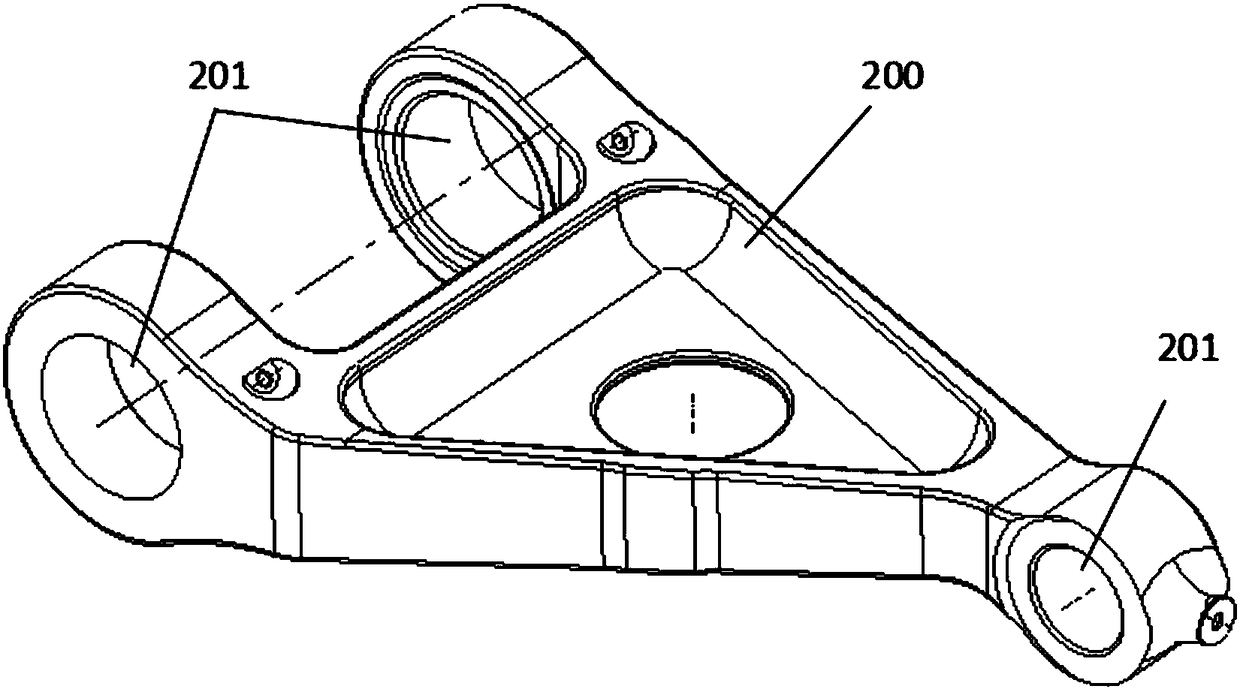

[0036] Such as figure 1 , the aircraft landing gear bracket workpiece 200 has a total of three through holes 201 at the front and rear and a plate body in the middle, which is triangular as a whole;

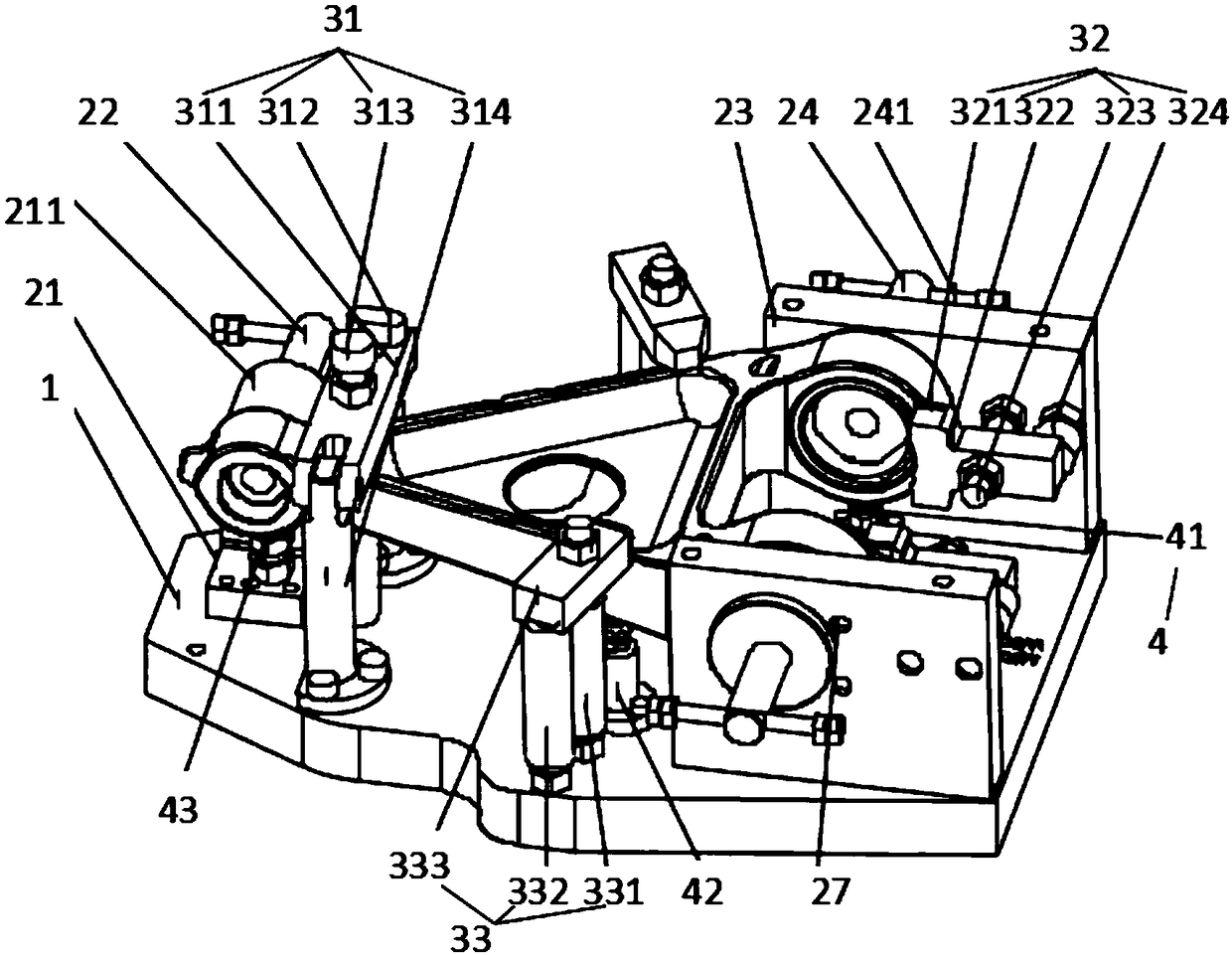

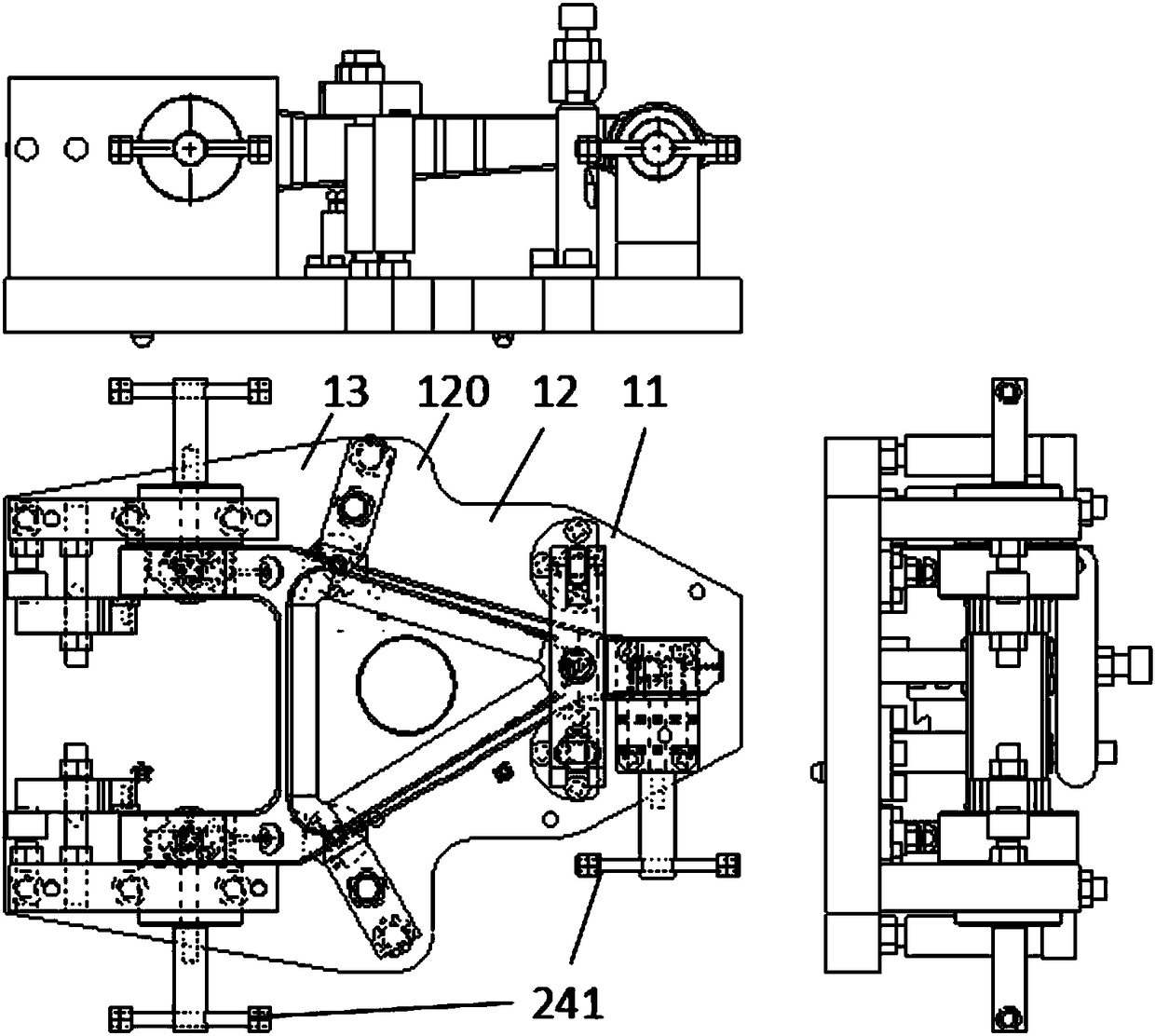

[0037] Such as Figure 2~5, a high-efficiency and high-precision fixture 100 for an aircraft landing gear bracket, used for clamping an aircraft landing gear bracket workpiece 200, including a clamp base plate 1, a fixing component 2, a pressing component 3, and an auxiliary positioning member 4. The clamp base plate 1 is from the previous It includes a front part 11, a neck 12 and a rear part 13 which is wider than the front part 11; the neck 12 is narrowed and then expanded from front to back, and the expanded part of the neck 12 is convex Part 120;

[0038] The fixed assembly 2 includes a dovet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com