Balance compensation structure and mode for three hanging points of spindle box

A technology of balance compensation and spindle box, which is applied to other manufacturing equipment/tools, parts of boring machine/drilling machine, drilling/drilling equipment, etc., can solve problems such as headstock tilt, to ensure machining accuracy, ensure movement accuracy, Craft and Control Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

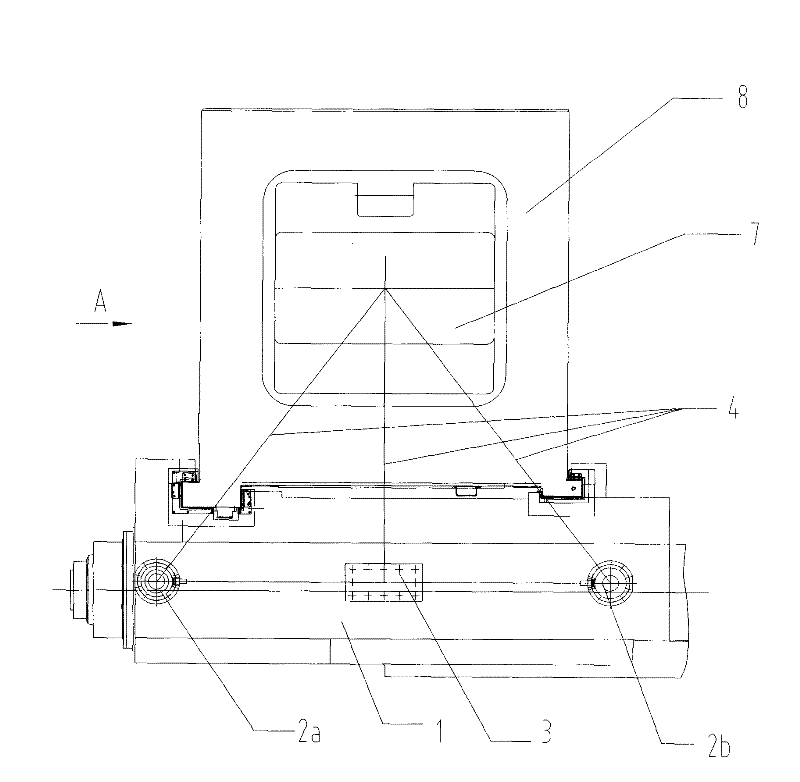

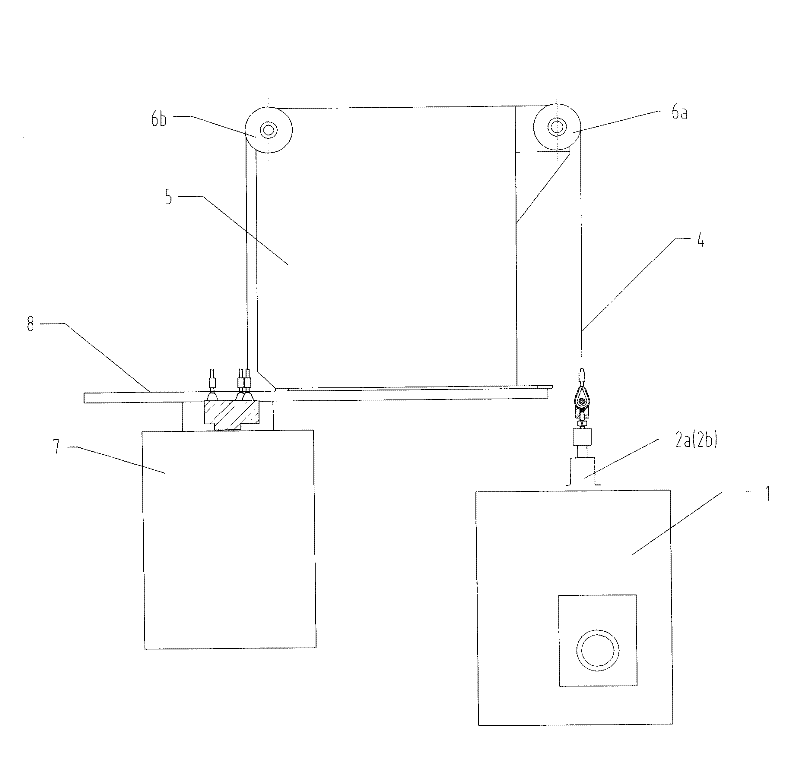

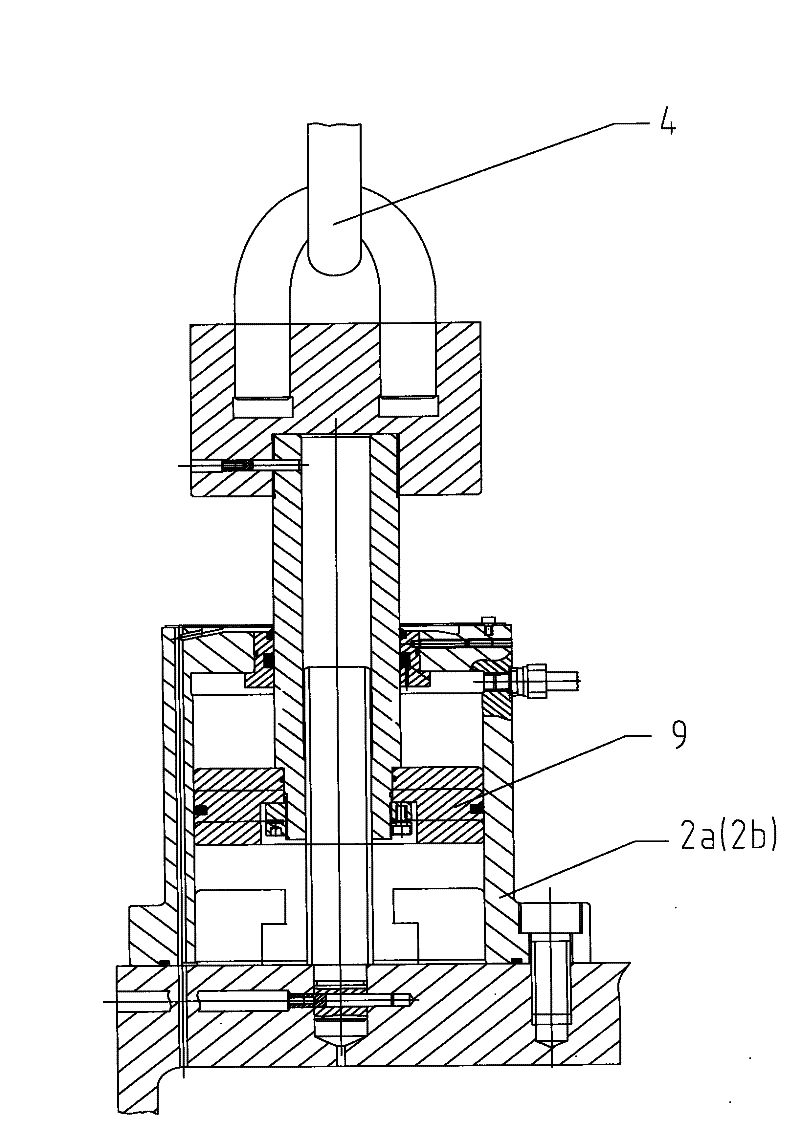

[0018] The balance compensation structure and method of the three suspension points of the spindle box in the present invention are mainly composed of the three suspension point mechanism of the spindle box, that is, the spindle box, the pulley mechanism, the connecting rope, the counterweight, and the tilt compensation unit. attached figure 1 Provided in the present invention is a schematic diagram of an embodiment of the three-suspension point balance compensation structure and method. On the horizontal axis of the center of gravity of the headstock 1, there are three lifting points, front, middle and rear, and the center of gravity of the headstock moves between the front and rear lifting points; there are three lifting points on the headstock 1. The front and rear compensation oil cylinders 2a and rear compensation oil cylinders 2b are respectively set at the two lifting points. The connecting rope 4 of the two lifting points is set on the top of the front compensation oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com