Diaphragm-type pressure reducing valve with high-pressure entering and low-pressure discharging

A pressure reducing valve, diaphragm type technology, applied in the direction of lift valve, valve details, safety valve, etc., can solve the problems of easy deformation of the valve seat, weak pressure bearing capacity, and reduced accuracy of the pressure reducing valve, so as to improve the overall strength, The effect of increasing the bearing pressure and increasing the bearing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

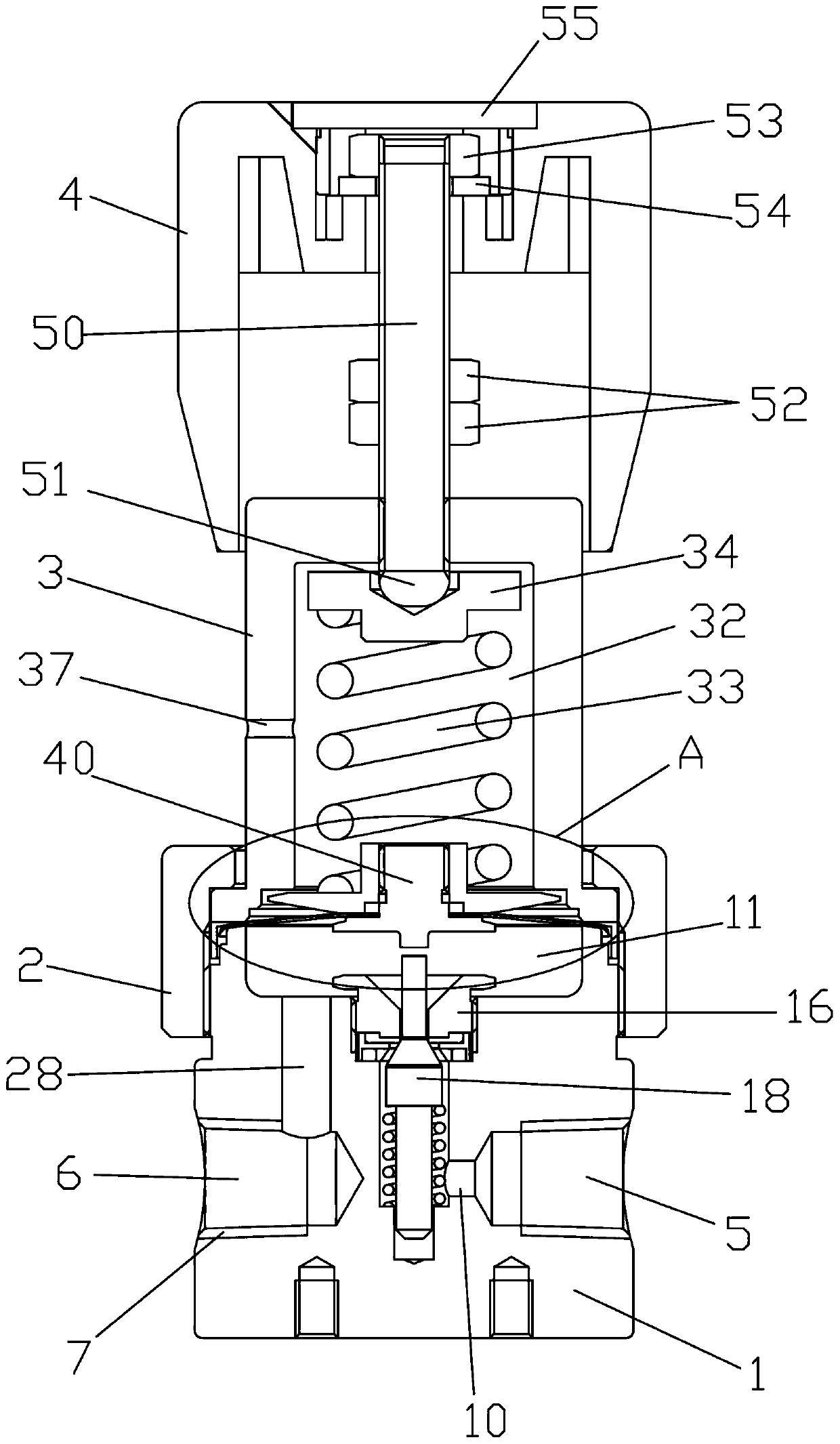

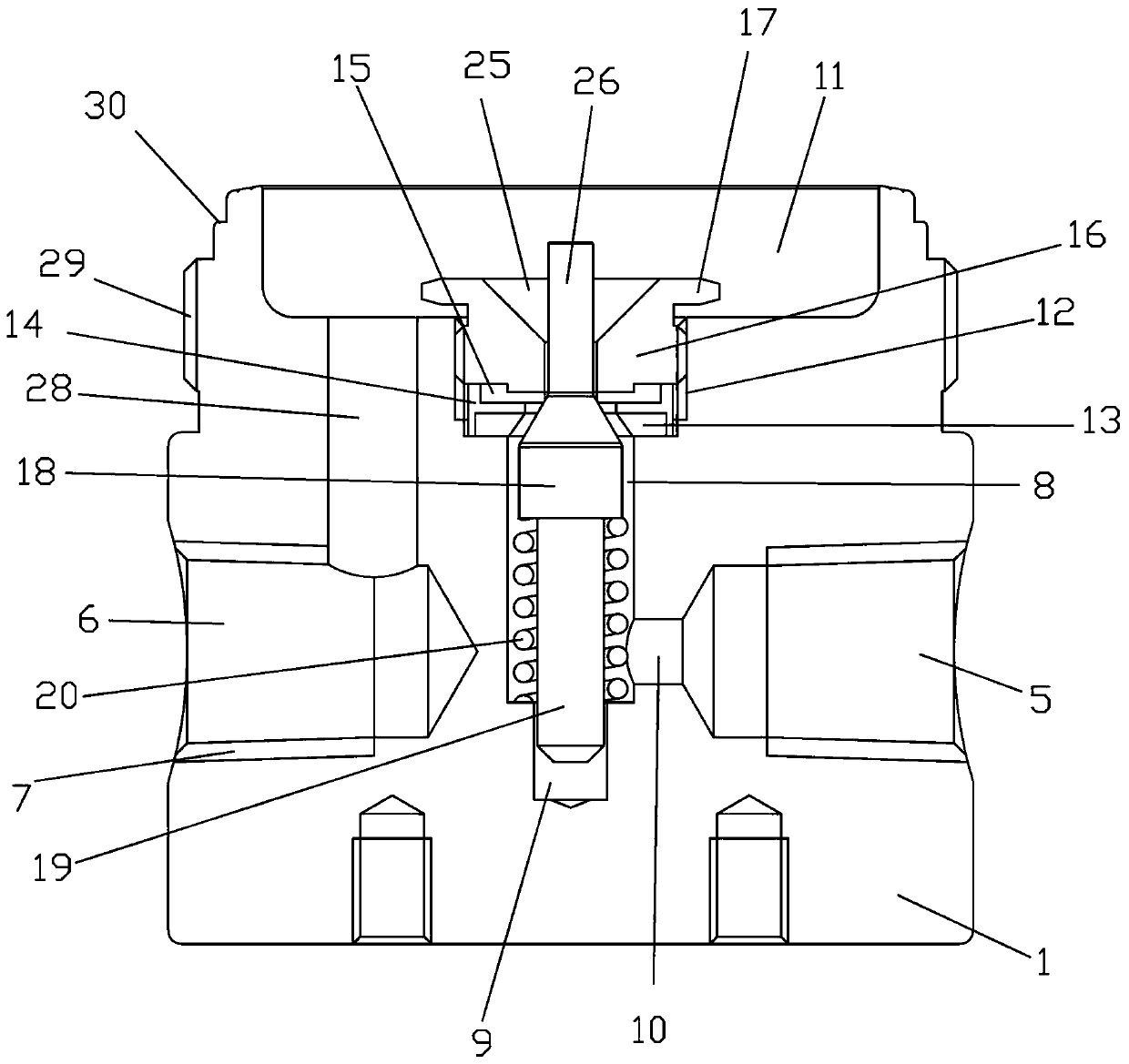

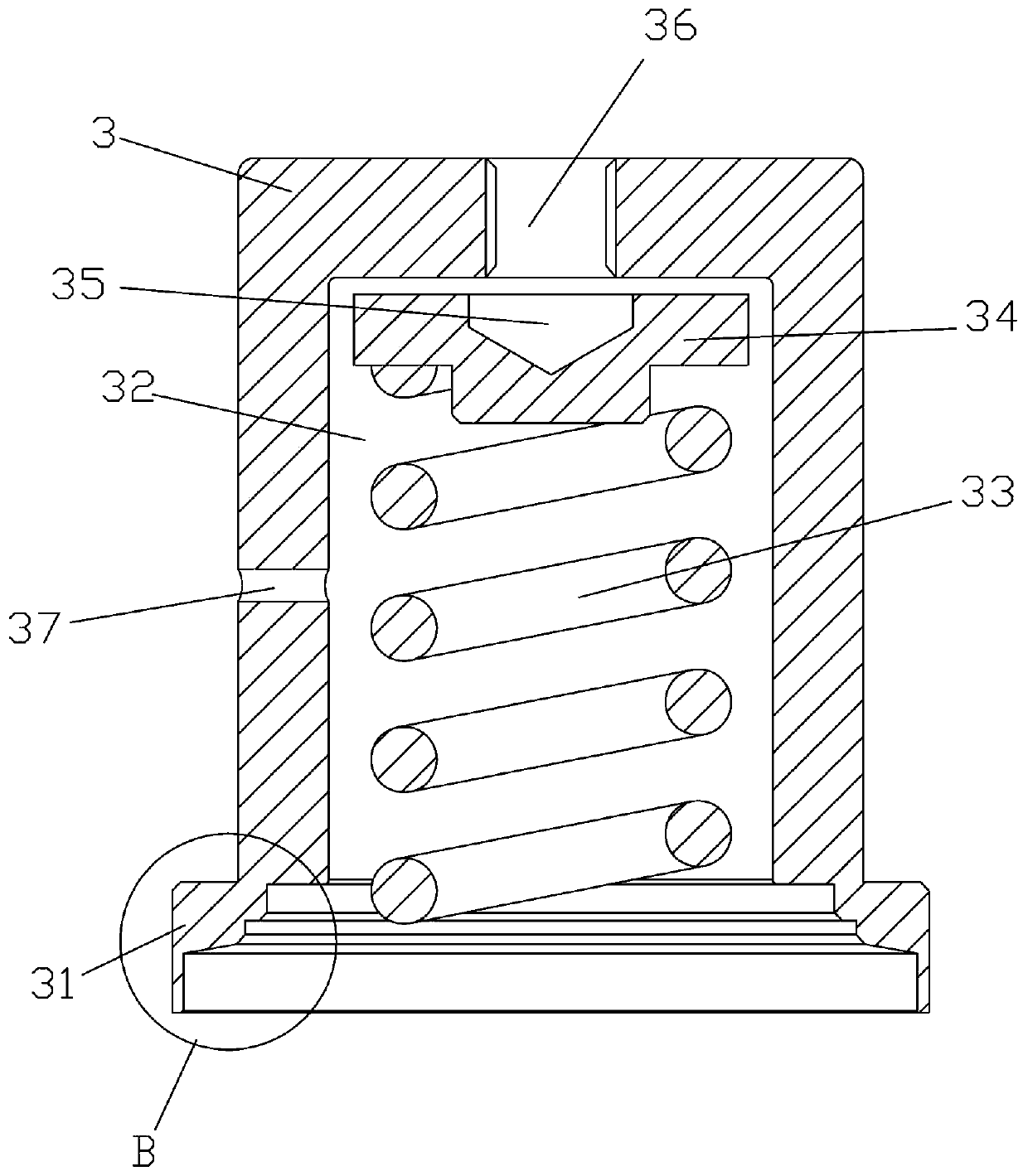

[0025] Embodiment: a kind of diaphragm pressure reducing valve that enters high pressure and exits low pressure, such as Figure 1-Figure 10 As shown, it includes a pressure reducing valve body, a bonnet nut, a bonnet and a handle, and is characterized in that the lower right side of the pressure reducing valve body is provided with an air inlet hole, and the lower left side of the pressure reducing valve body is provided with an air outlet hole , the inner rings of the air inlet hole and the air outlet hole are provided with internal threads, the middle part of the pressure reducing valve body is vertically provided with a valve stem cavity, and the center of the bottom of the valve stem cavity is provided with a valve stem pin positioning hole, The outer diameter of the valve stem pin positioning hole is smaller than the inner diameter of the valve stem cavity, and a first vent hole is provided between the lower right side of the valve stem cavity and the air intake hole, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com