Pressure reducing valve control

A pressure reducing valve and pilot valve technology, applied in the direction of fluid pressure control, auxiliary non-electric fluid pressure control, non-electric variable control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

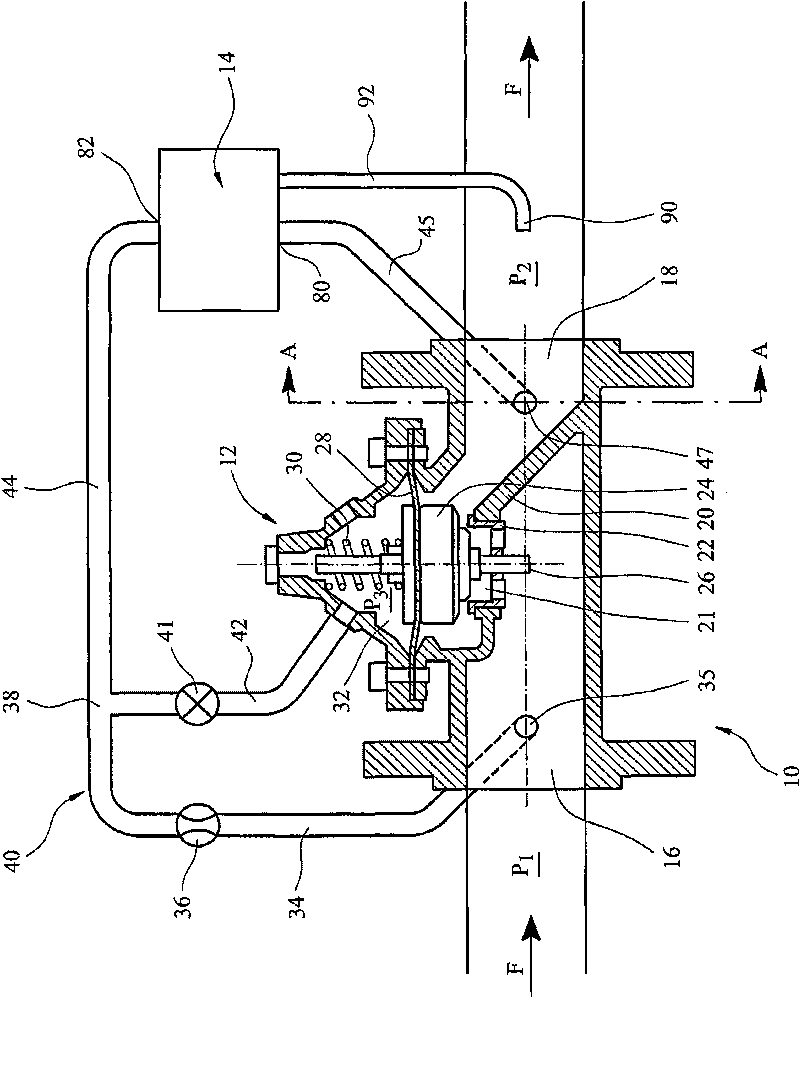

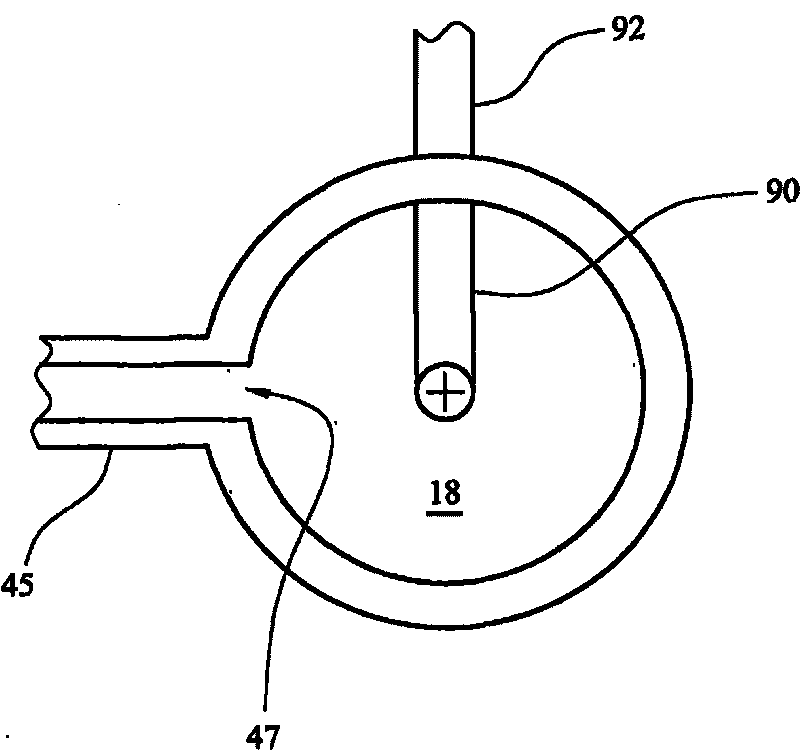

[0037] refer to figure 1 , the pressure reducing system 10 for water supply includes a primary pressure reducing valve (PRV) 12 and a pilot control valve 14 . The main PRV 12 is conventional and includes an inlet 16 and an outlet 18 connected to the water supply to carry water through the main valve 12 in the direction indicated by arrow F and to forwarded to consumers. Said inlet 16 and outlet 18 are interconnected by a valve seat 22 defining a bore 21 through a partition wall 20 of valve 12 . The valve body 24 is mounted on a valve stem 26 for movement toward and away from the valve seat 22 . The valve body 24 is mounted on a flexible diaphragm 28 above which is located a main valve bias spring 30 and a chamber referred to as a control volume 32 . The position of valve body 24 relative to valve seat 22 opens or closes valve 12 , thereby determining the pressure drop across valve 12 and between inlet 16 and outlet 18 . When the valve body 24 is close to the valve seat 22,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com