Adjustable pressure reducing pore plate

A decompression hole, adjustable technology, applied in the direction of sliding valves, valve details, engine components, etc., can solve the problems of non-replacement, many objective factors, large amount of calculation data, etc., and achieve the effect of wide application range and avoiding pressure errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, so as to help understand the content of the present invention.

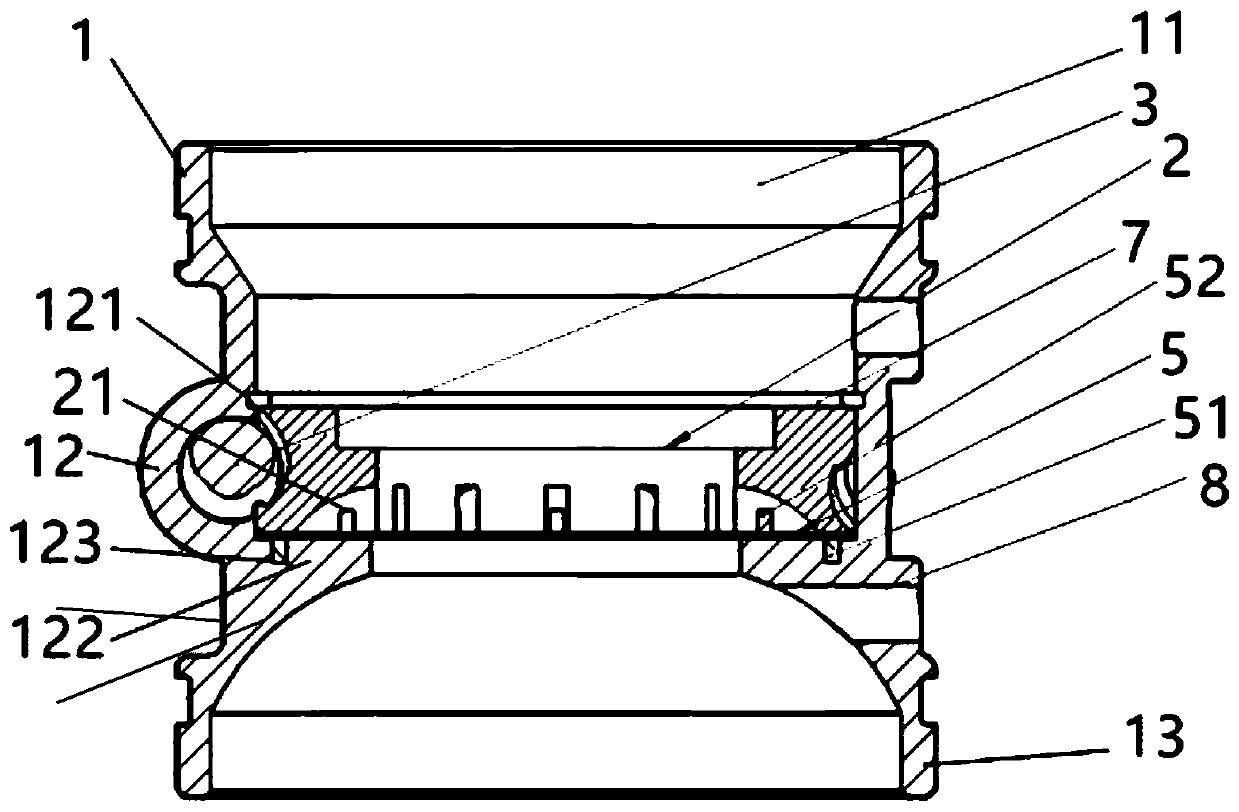

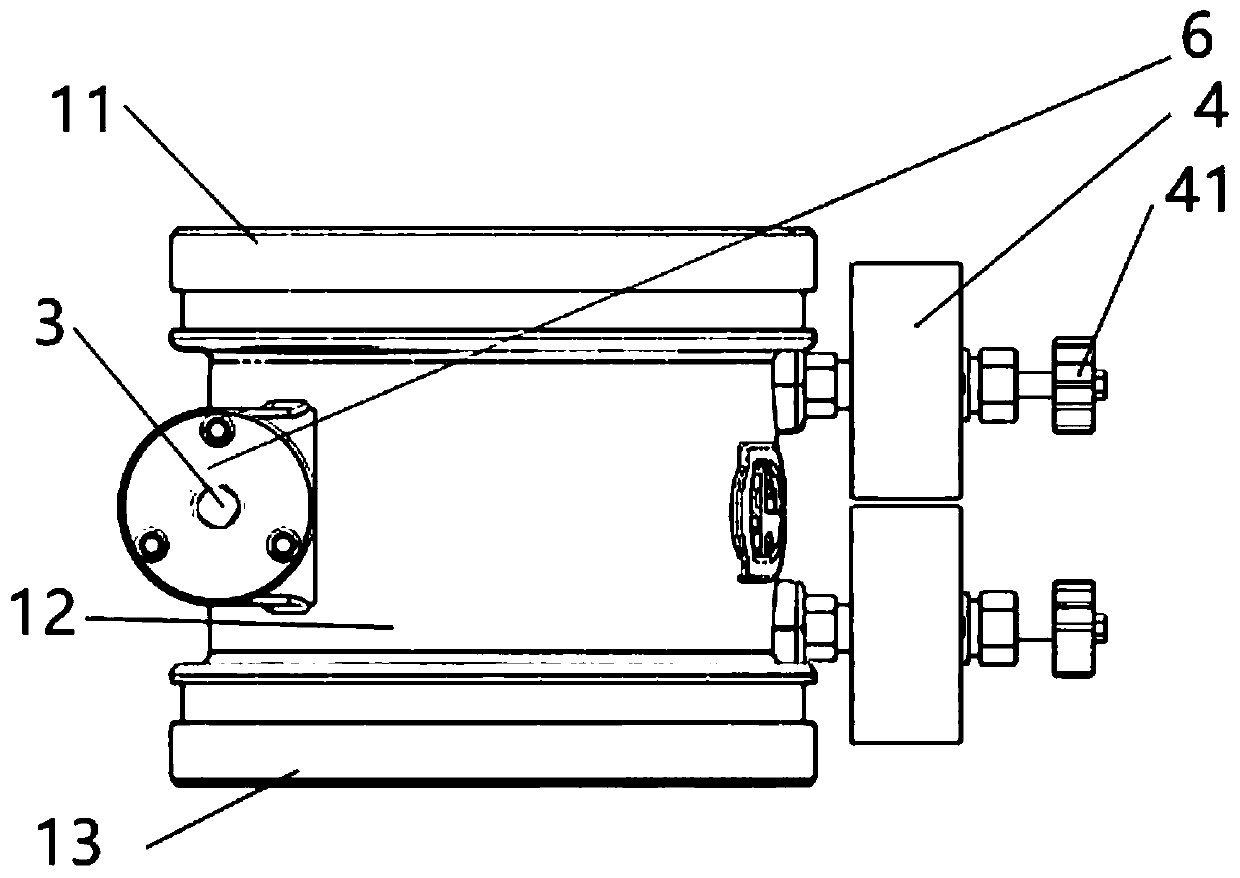

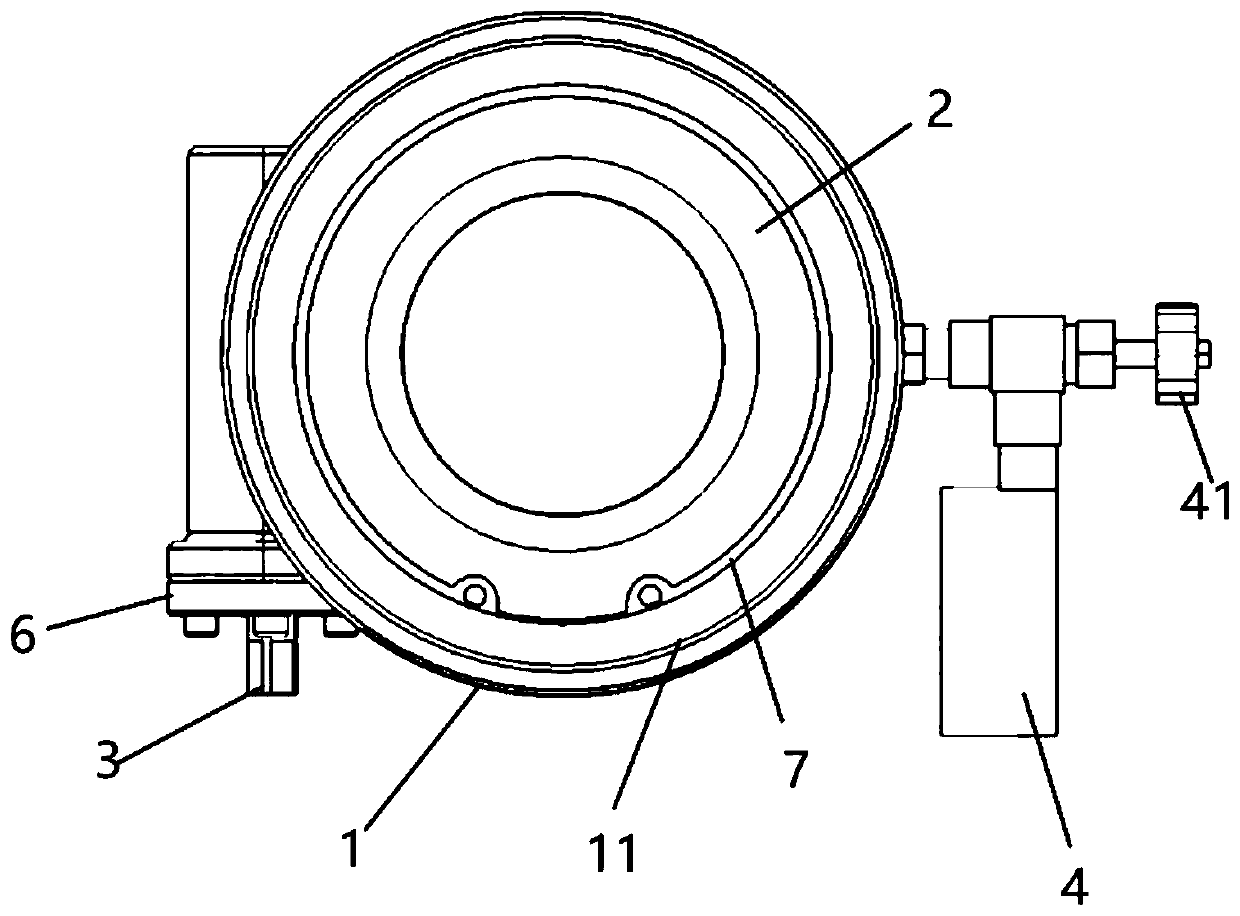

[0021] Such as Figure 1-4 As shown, an adjustable decompression orifice plate provided by the present invention includes a casing 1, which is integrally cast from ductile iron, with high strength and good corrosion resistance. The housing 1 is sequentially provided with a water inlet 11, an installation part 12 and a water outlet 13 coaxially connected with each other from the water inlet to the water outlet. The gauge installation hole 8 is provided with a gauge valve 41 on the pressure gauge 4 and is used for monitoring the pressure of the pipe network. The water inlet port of the water inlet part 11 and the water outlet port of the water outlet part 13 are respectively provided with internal threads or external threads matching the external threads or internal threads of the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com