A digital display flowmeter with a pressure measuring tube display for experimental teaching and its measurement method

A pressure measuring tube and flowmeter technology, which is applied in the field of experimental measurement, can solve the problems of automatic exhaust of multiple pressure measuring tubes, short circuit of gas circuit, low or even close to atmospheric pressure, etc., and achieves the effect of good teaching effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

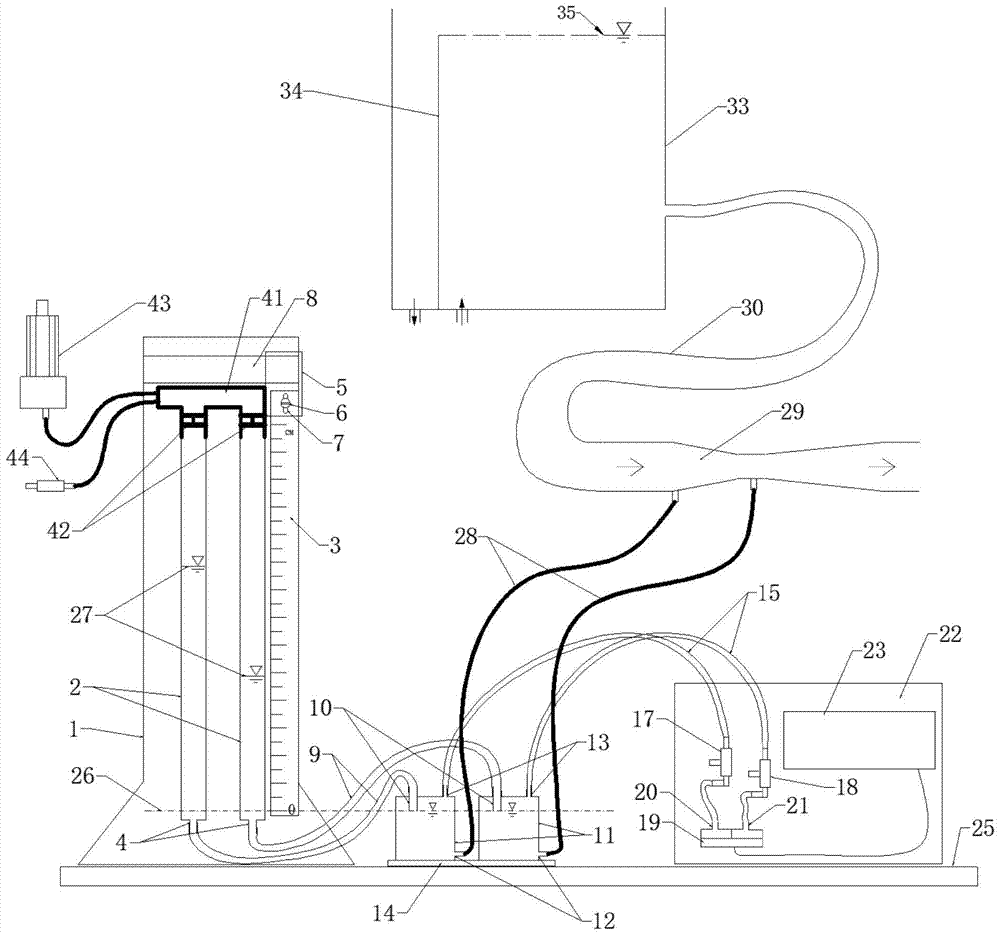

[0055] as attached figure 1 As shown, it is a digital display flowmeter with a piezometric tube display for experimental teaching of the present invention, including: a differential pressure flow signal generator 29 for generating a differential pressure signal, and a differential pressure flow signal generator 29 with a There are two pressure measurement points; two sets of pressure measurement components, each group of pressure measurement components includes a pressure measurement cylinder 11, each pressure measurement cylinder 11 is provided with a water inlet 12 at the bottom, and a connecting positioning tube 10 at the top, which is connected with the positioning tube 10 connected to the pressure measuring tube 2; two groups of pressure measuring components are respectively connected to the two pressure measuring points of the differential pressure flow signal generator 29 through the water inlet 12 of the lower part of the pressure measuring cylinder 11 respectively; Tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com