A row-type pressure measuring device with roving electric measuring digital display

A pressure measuring device and pressure measuring technology, applied in the field of experimental measurement, can solve the problems of experimental adjustment trouble, measurement error accumulation and superposition, high cost, etc., achieve the best teaching effect and reduce the effect of superposition error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

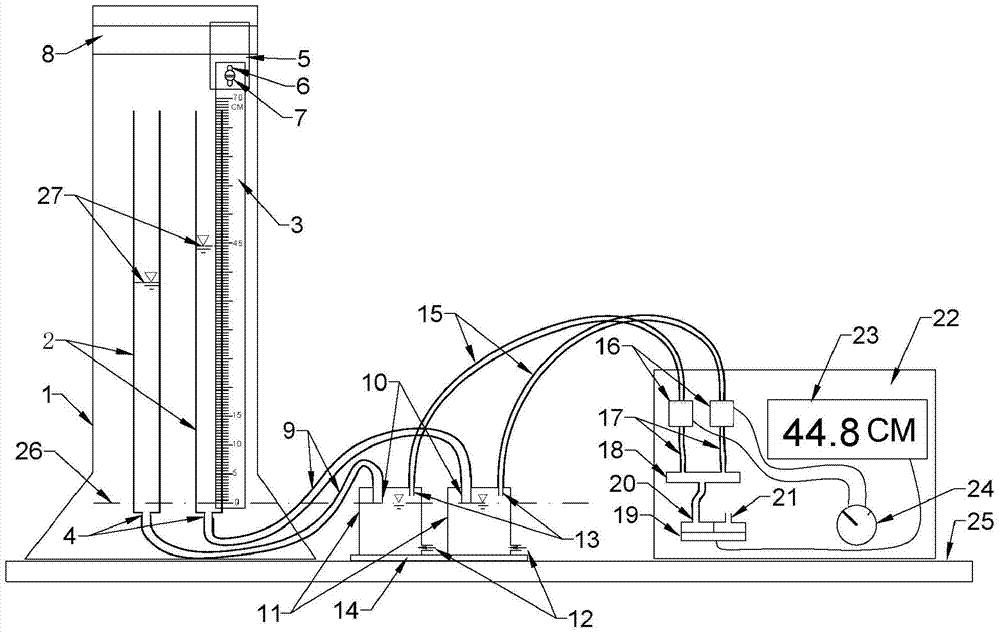

[0050] like figure 1 As shown, it is a row-type pressure measuring device with circuit electric measurement and digital display of the present invention, comprising: more than two groups of pressure measuring components, each group of pressure measuring components includes: a pressure measuring cylinder 11, a The communication positioning tube 10, the pressure measuring tube 2 connected to the communication positioning tube 10, the conduit (the vent tube 13 and the ventilation pressure measuring hose 15) communicated with the compressed air in the pressure measuring cylinder 11, and the conduit (the vent tube 13 and the ventilation tube 15) The valve 16 on the pressure measuring hose 15); the differential pressure sensor 19, two or more pressure measuring components are connected to the differential pressure sensor 19 through their respective valves 16; Ruler 3.

[0051] The bottom surface of the communication positioning pipe 10 in each pressure measuring assembly is at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com