Grating Talbot image-based object surface curvature detection system and method

A technology for object surface and curvature detection, applied in measurement devices, optical devices, instruments, etc., can solve the problems of slow measurement speed, high measurement environment requirements, and high maintenance costs, and achieves simple installation, wide application range, and environmental resistance. The effect of strong interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

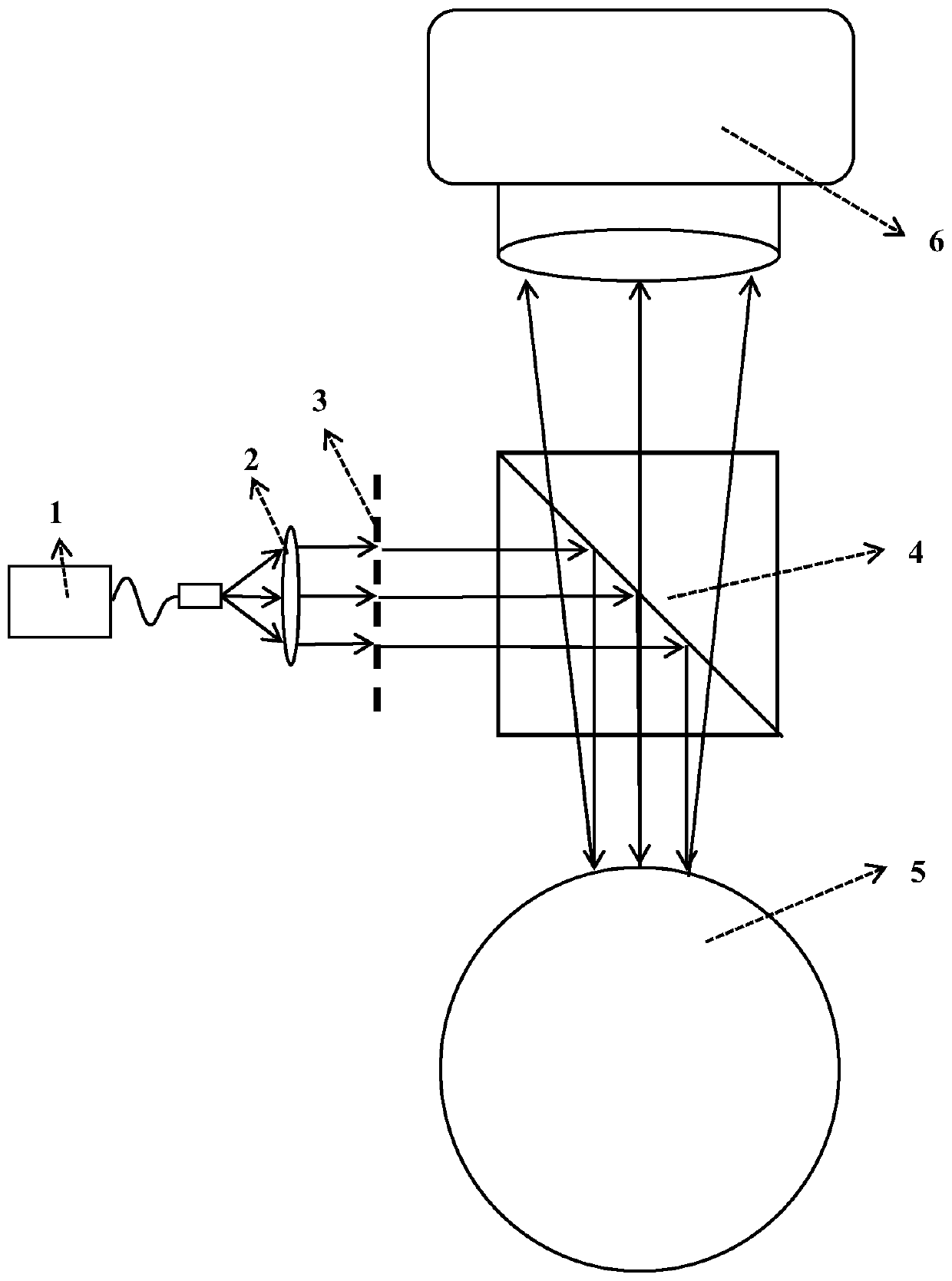

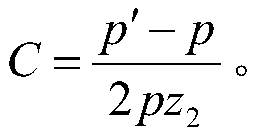

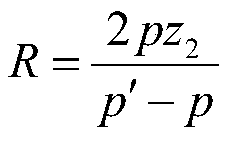

[0024] A surface curvature detection system based on a grating Taber image, including a laser 1, a collimator beam expander 2, a grating 3, a beam splitter 4, a ccd6, and a curvature calculation module. The beam mirror 2 is connected, and the grating 3 is set facing the collimator beam expander 2, and the beam splitter 4 is set so that the light transmitted through the grating 3 is reflected by the beam splitter 4 on the surface of the measured object 5, and the grating is clear. Taber image, the ccd6 is set so that the light beam reflected by the surface of the measured object 5 presents a Taber image with surface curvature information on the ccd6 through the beam splitter 4, and the curvature calculation module is used to collect the Taber image according to the collected Taber image. The curvature of the surface of the measured object is determined by the Bo image, the period of the Ronchi grating, and the optical path from the surface of the measured object to the ccd.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com