Grinding wheel dresser for grinding machine

A grinding wheel dresser and grinding machine technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, abrasive surface adjustment devices, etc., can solve the problems of time-consuming and labor-intensive dressing, poor versatility, etc., to ensure movement accuracy and reduce friction , Eliminate the effect of thread gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

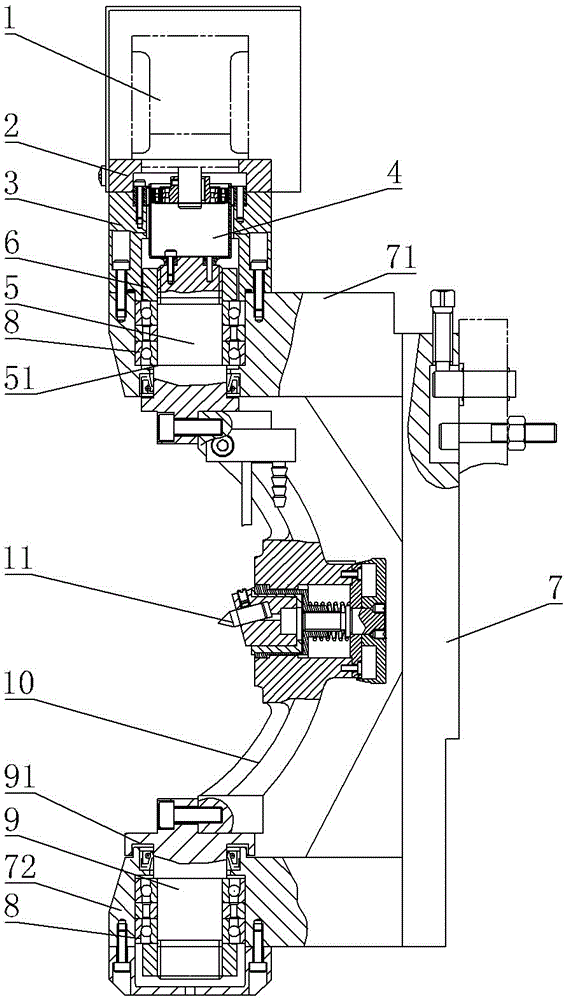

[0014] Such as figure 1 , figure 2 As shown, it includes a diamond pen 11, a swing rod 10, a base 7 and a driving device. The upper and lower ends of the swing rod 10 are correspondingly connected with rotating shafts 5, 9, and the rotating shafts 5, 9 are supported on the support arm on the base through bearings 8. 71. The shaft hole of the lower support arm 72, the driving device includes a servo motor 1 and a harmonic reducer 4, the output shaft of the servo motor 1 is connected to the input end of the harmonic reducer 4, and the output end of the harmonic reducer 4 is connected to the rotating shaft 5 connection, the servo motor 1 is fixed on the motor base 2, the harmonic reducer 4 is fixed on the reducer base 3, the motor base 2, the reducer base 3 and the upper support arm 71 of the machine base are fixedly connected in sequence;

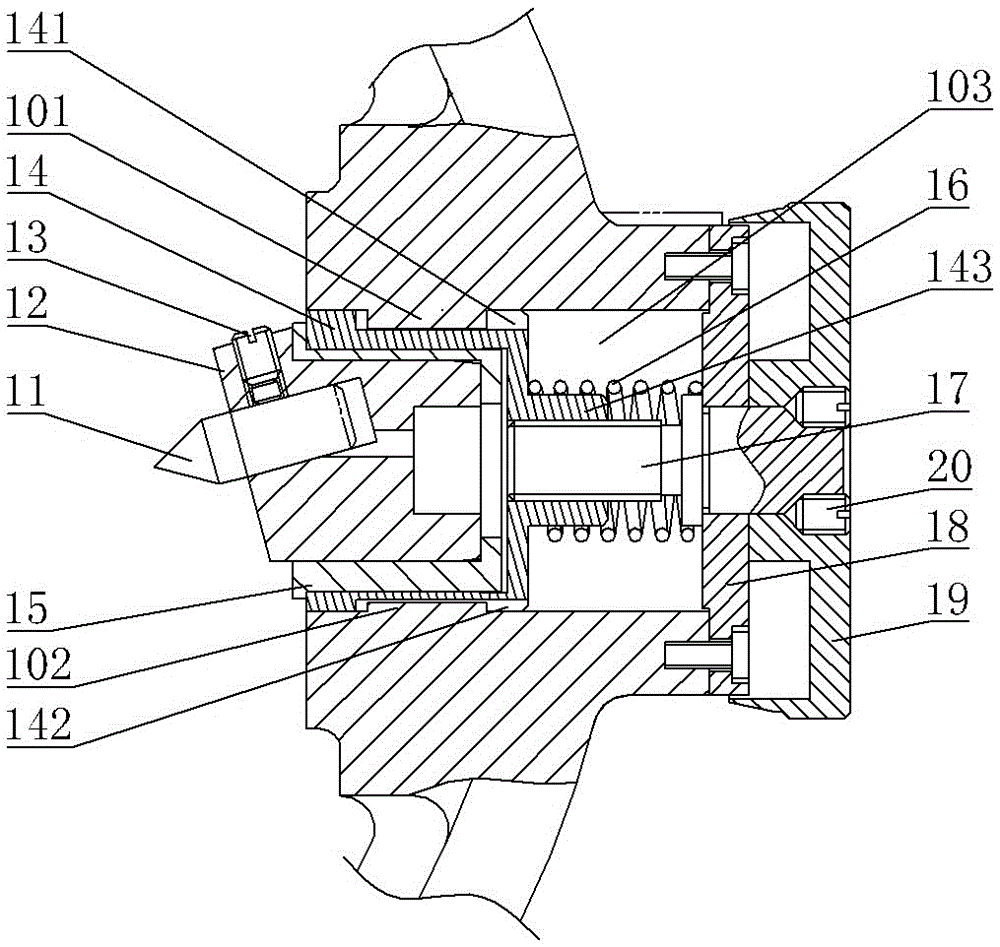

[0015] The swing rod 10 is provided with a shaft hole 103, and the shaft hole 103 is provided with a sliding sleeve 14, and the sliding sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com