Patents

Literature

32results about How to "Eliminate thread clearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

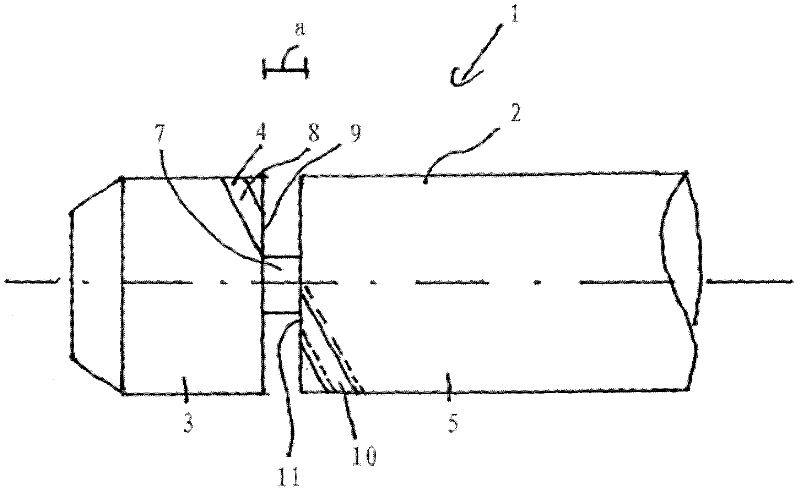

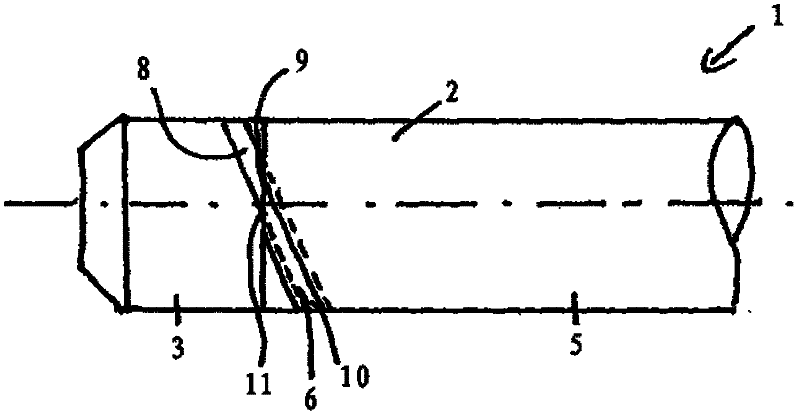

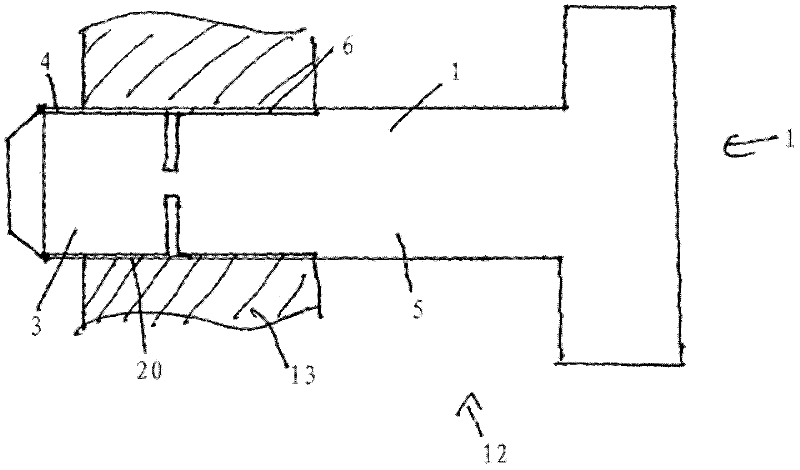

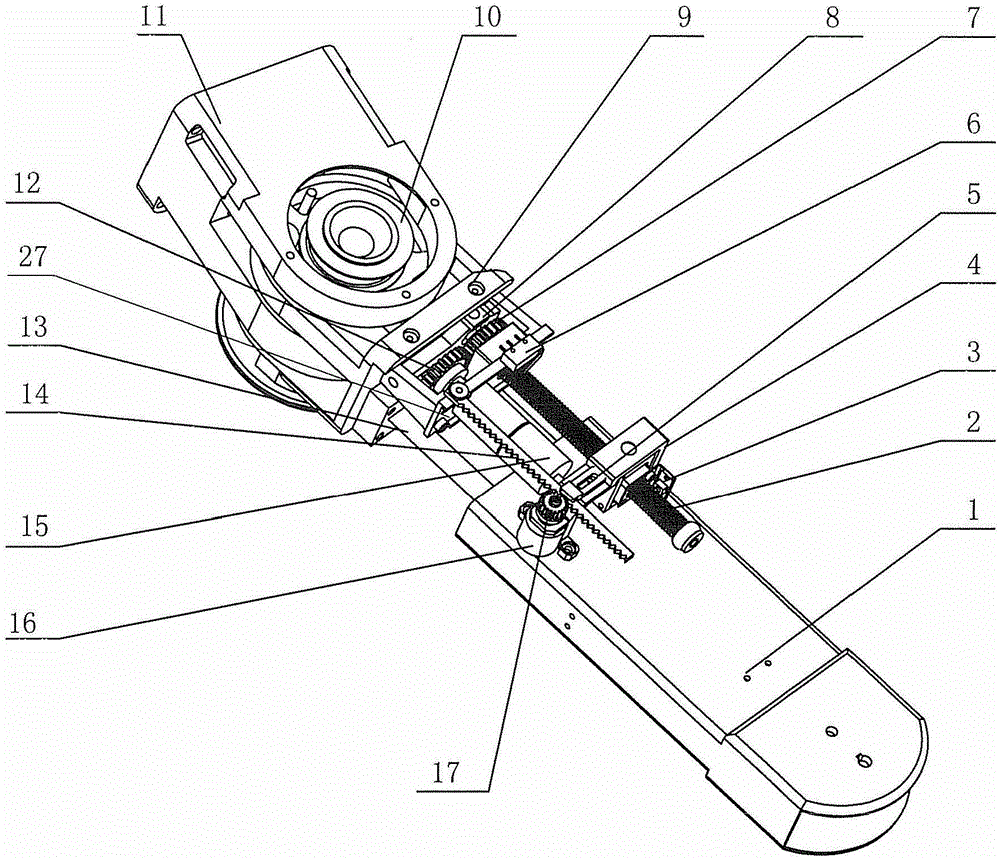

Dip angle regulating device

InactiveCN101187720AAchieve the purpose of the inventionIndependent adjustment of usage characteristicsSurveying instrumentsMountingsEngineeringMechanical engineering

Owner:ASIA OPTICAL CO INC

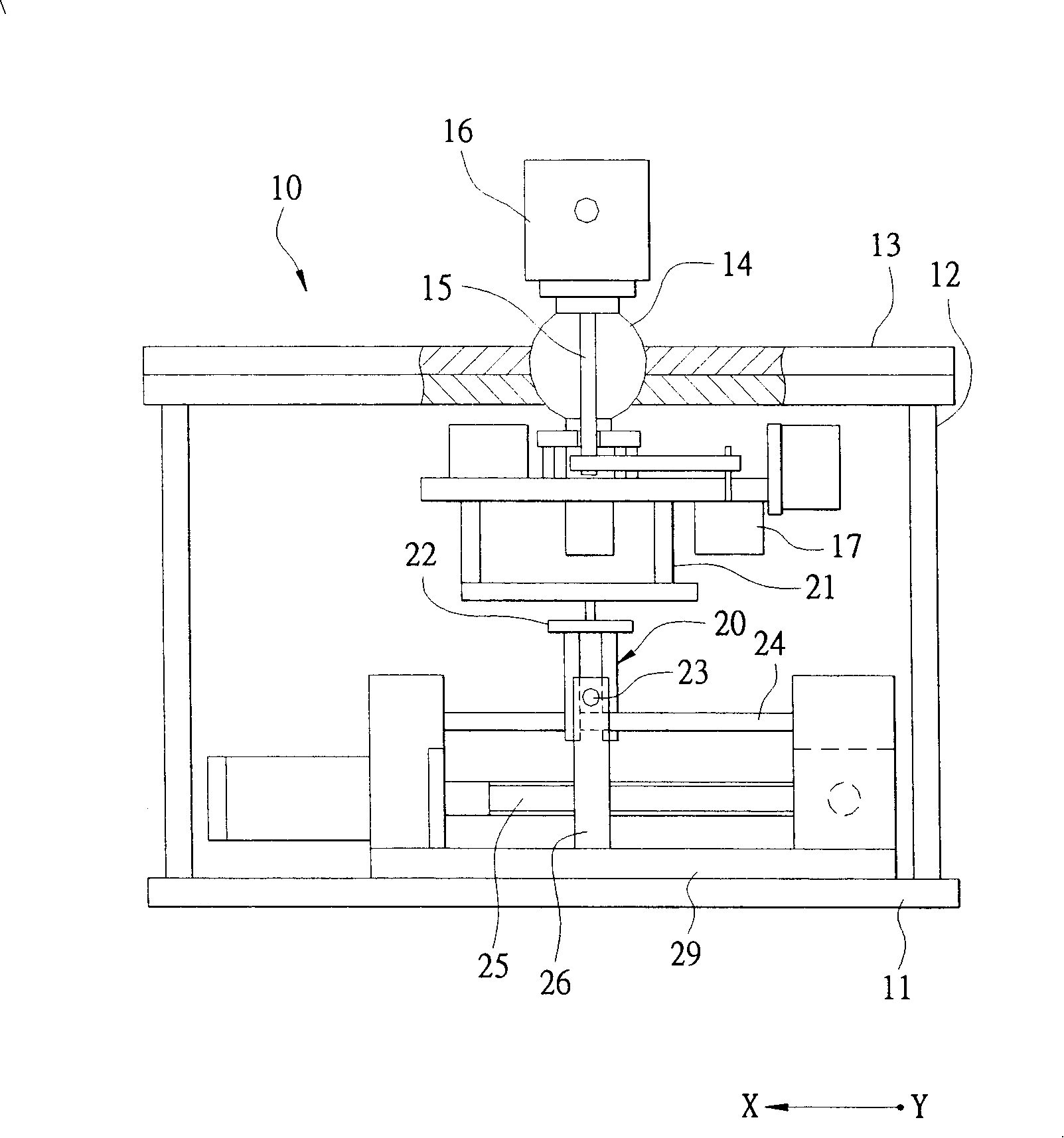

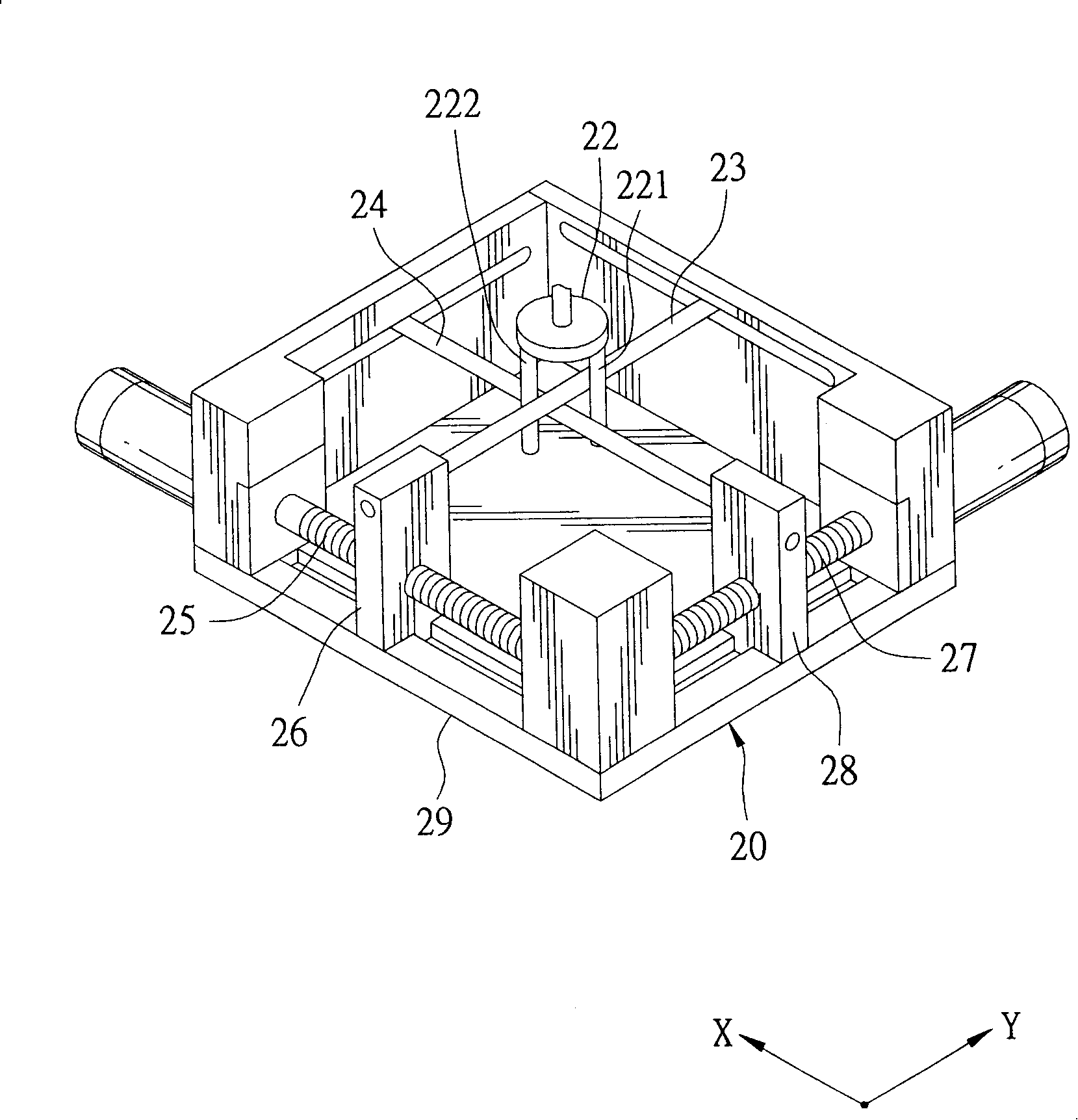

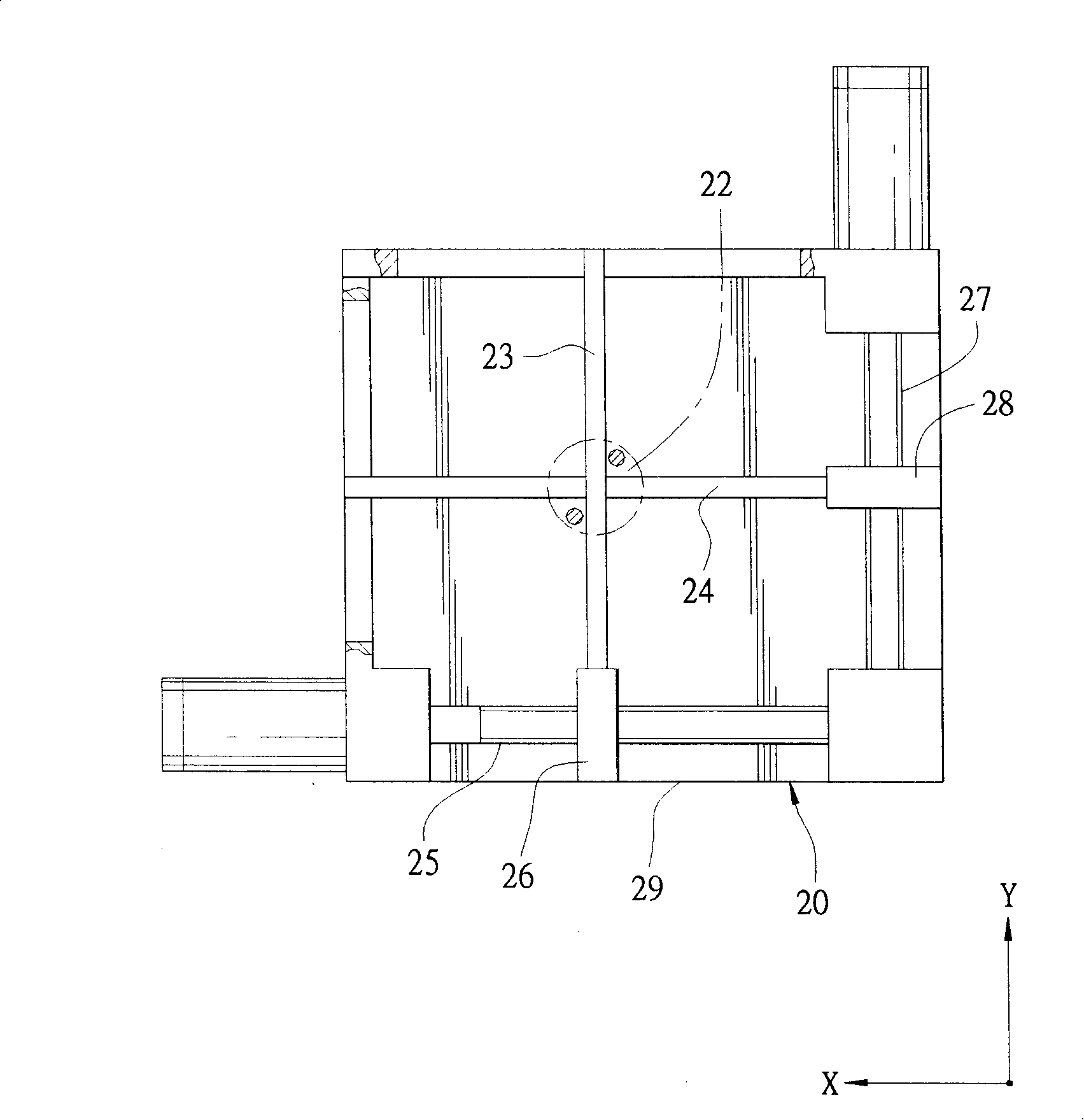

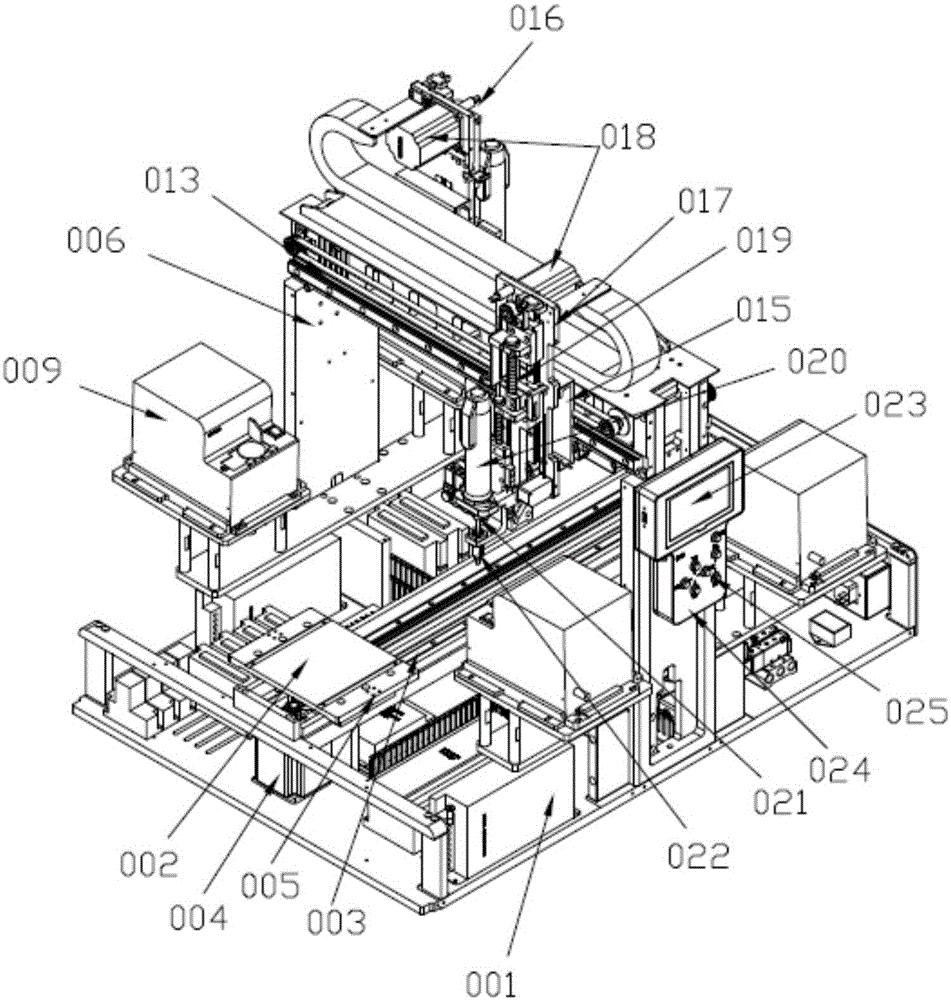

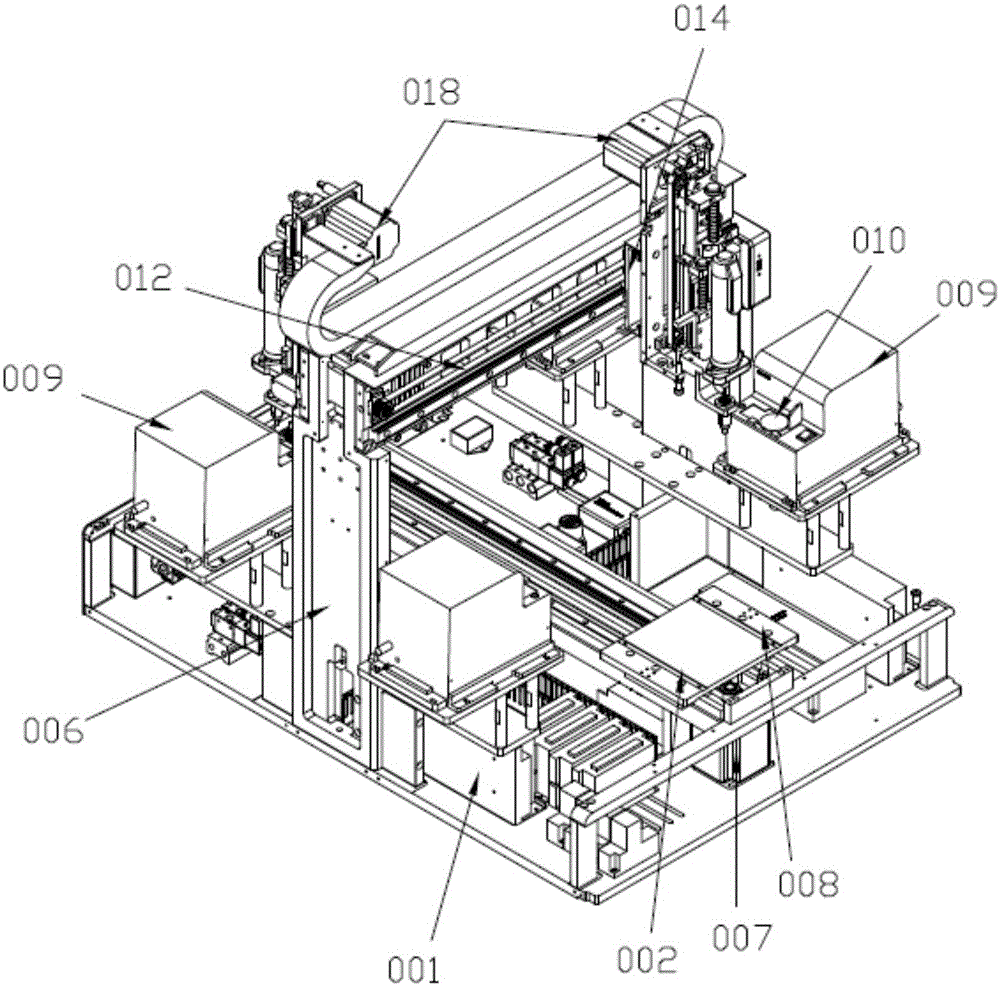

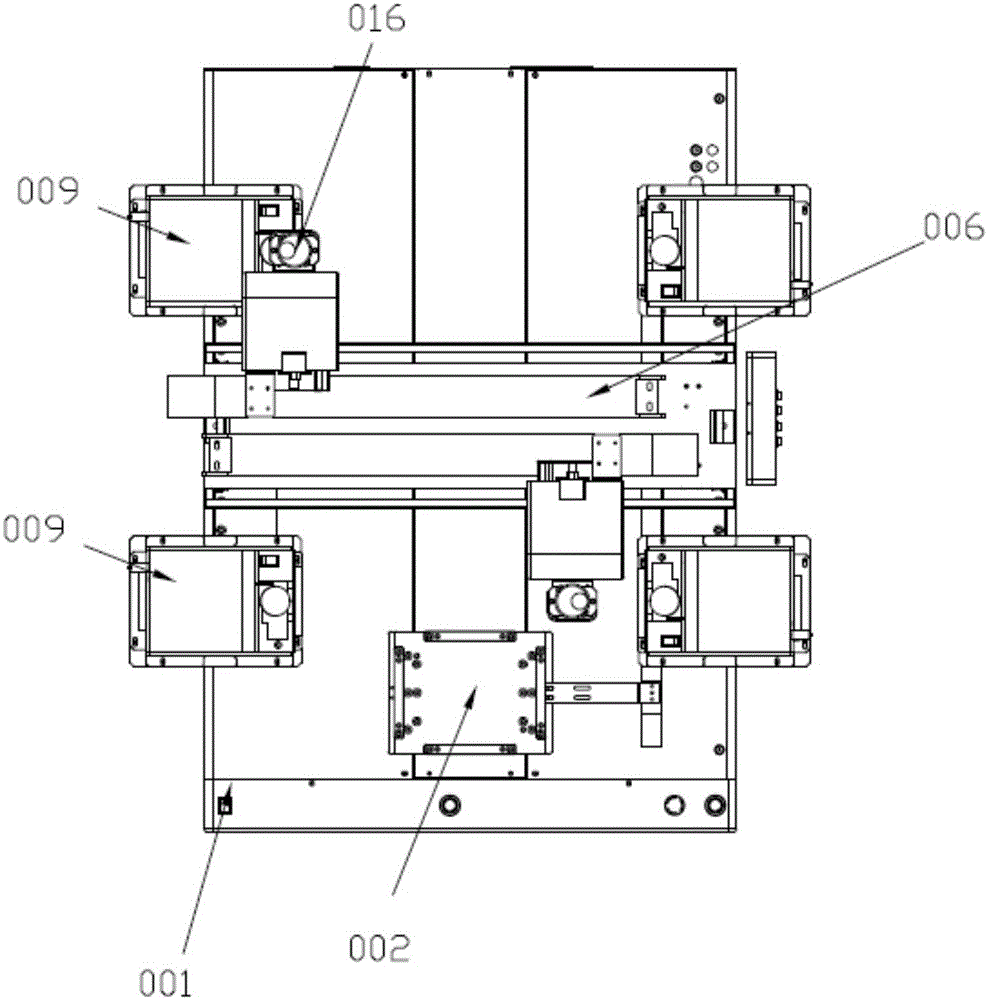

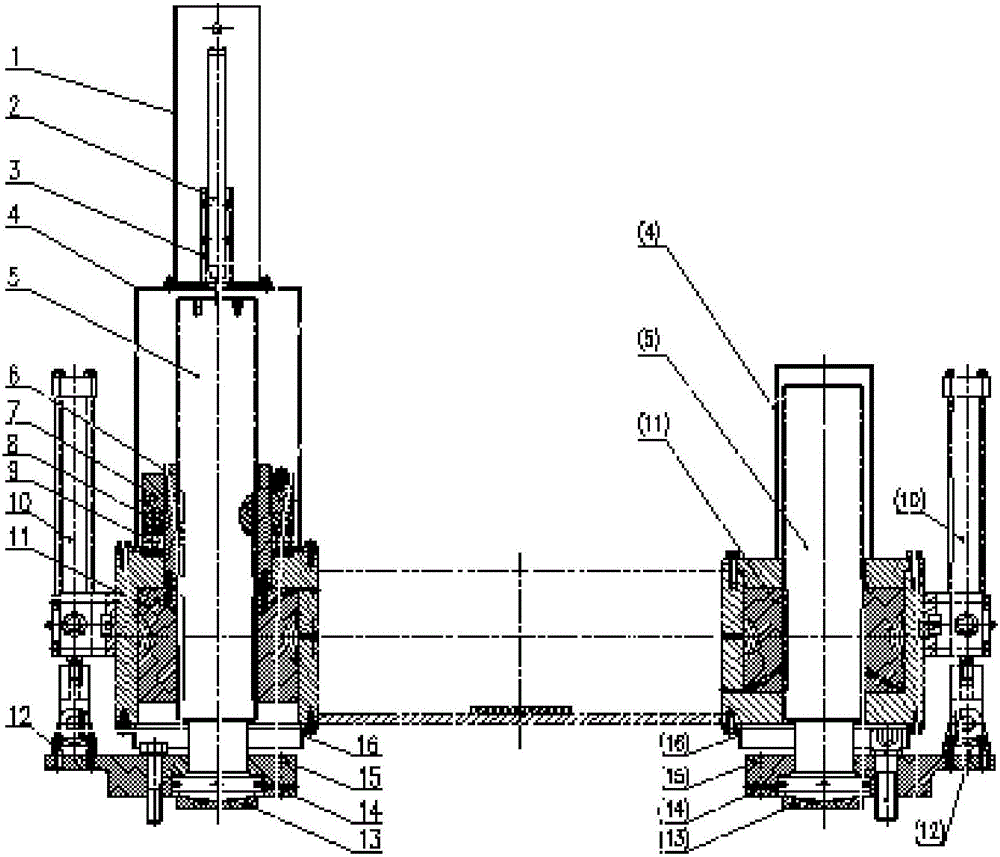

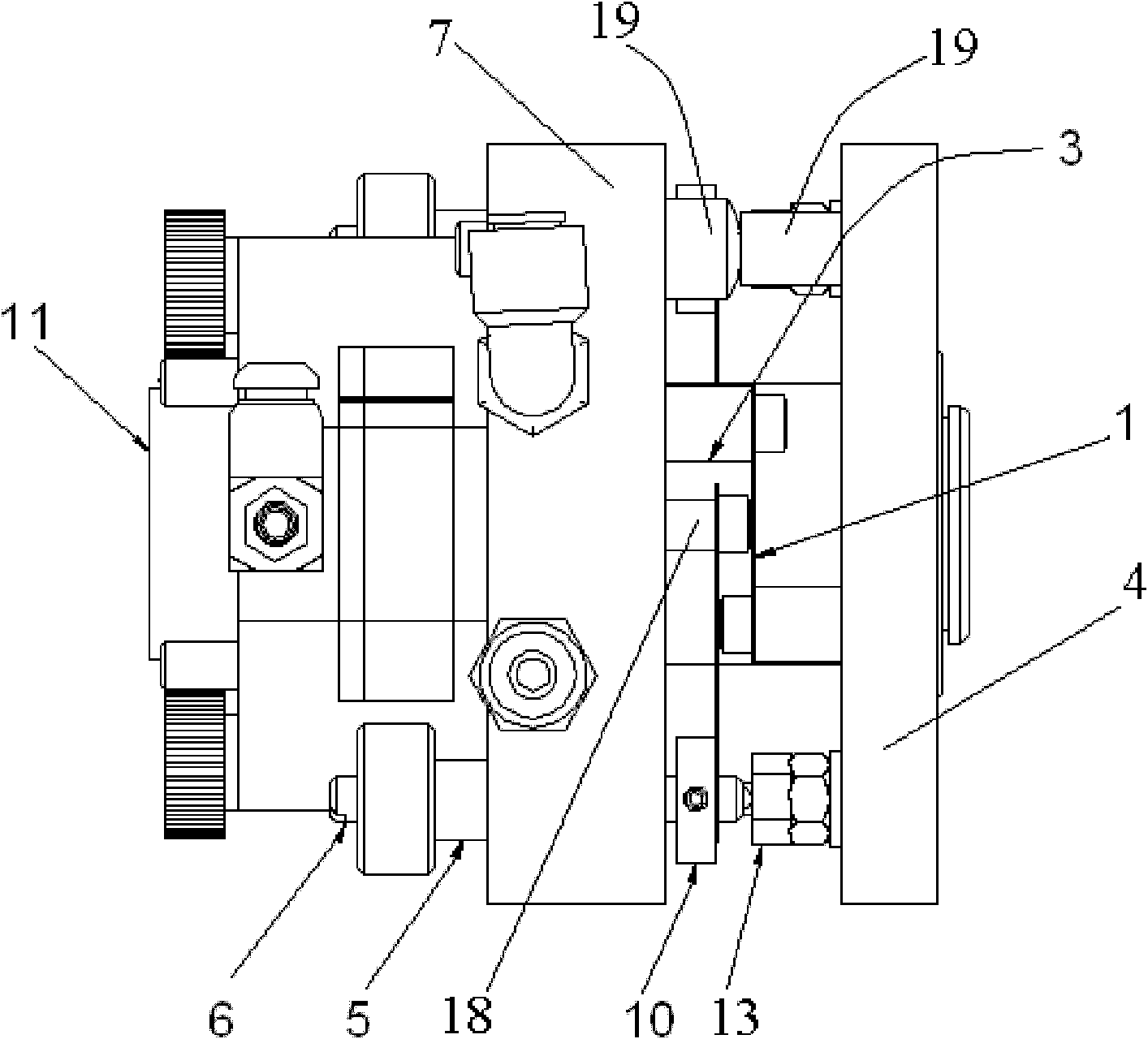

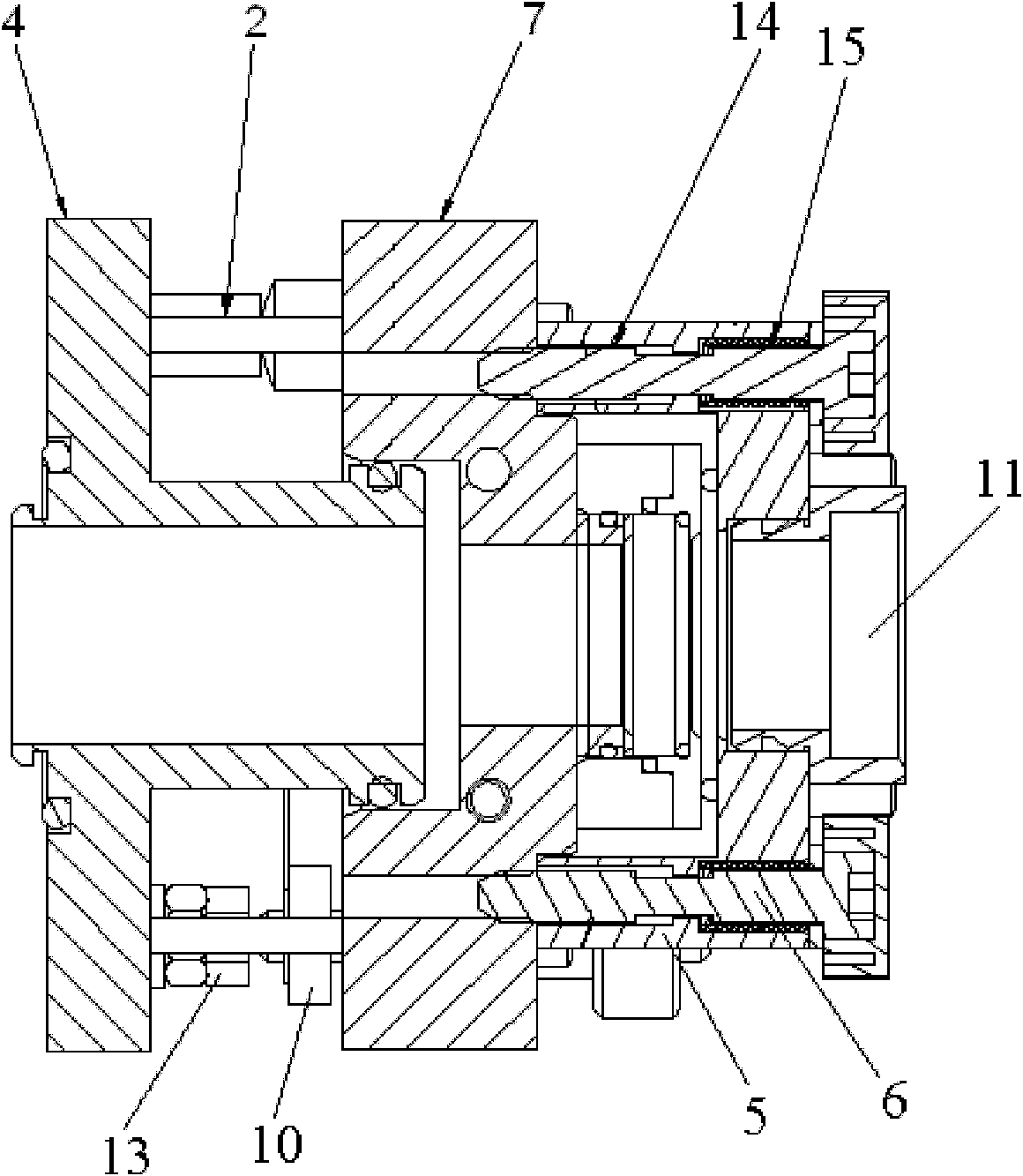

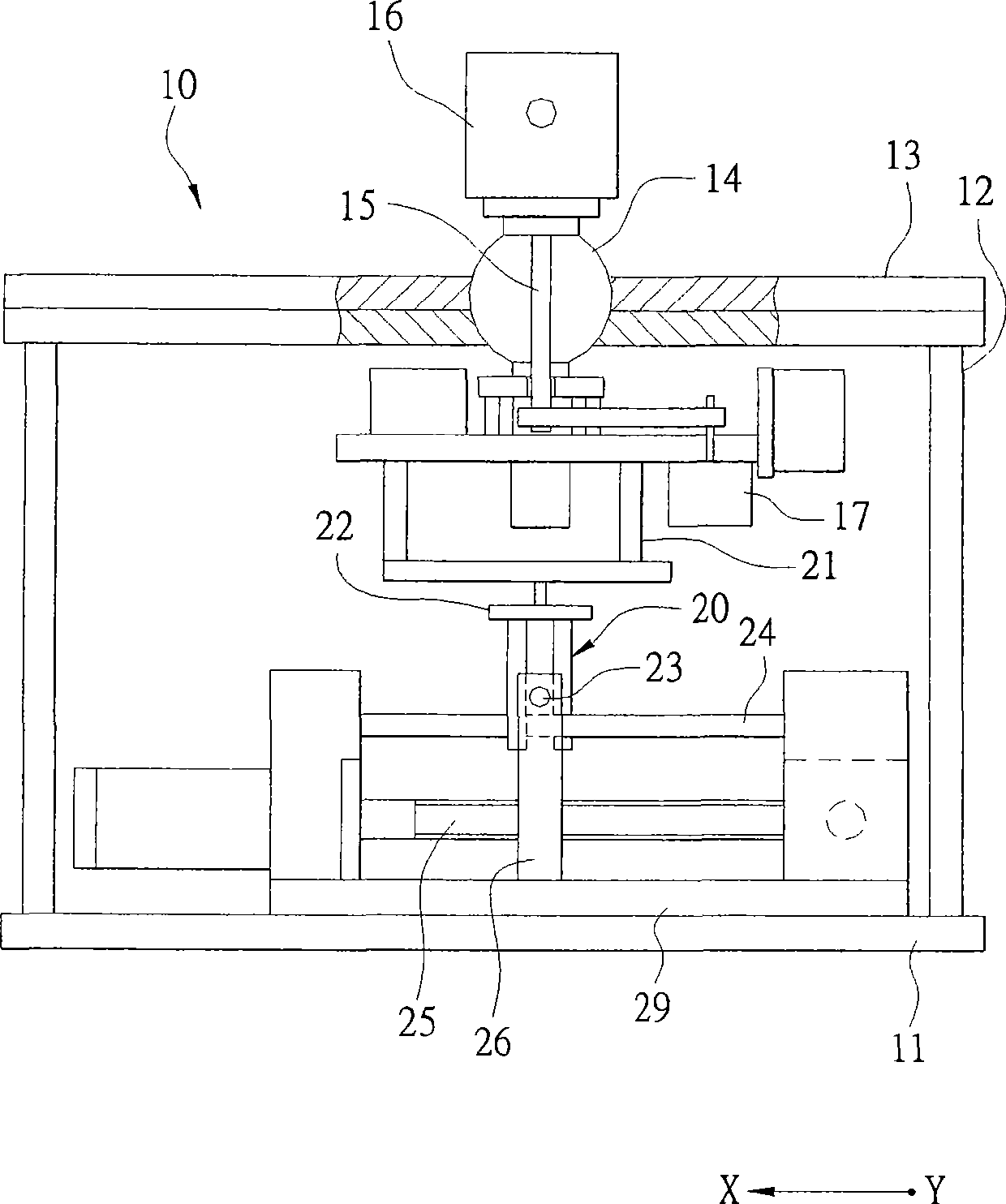

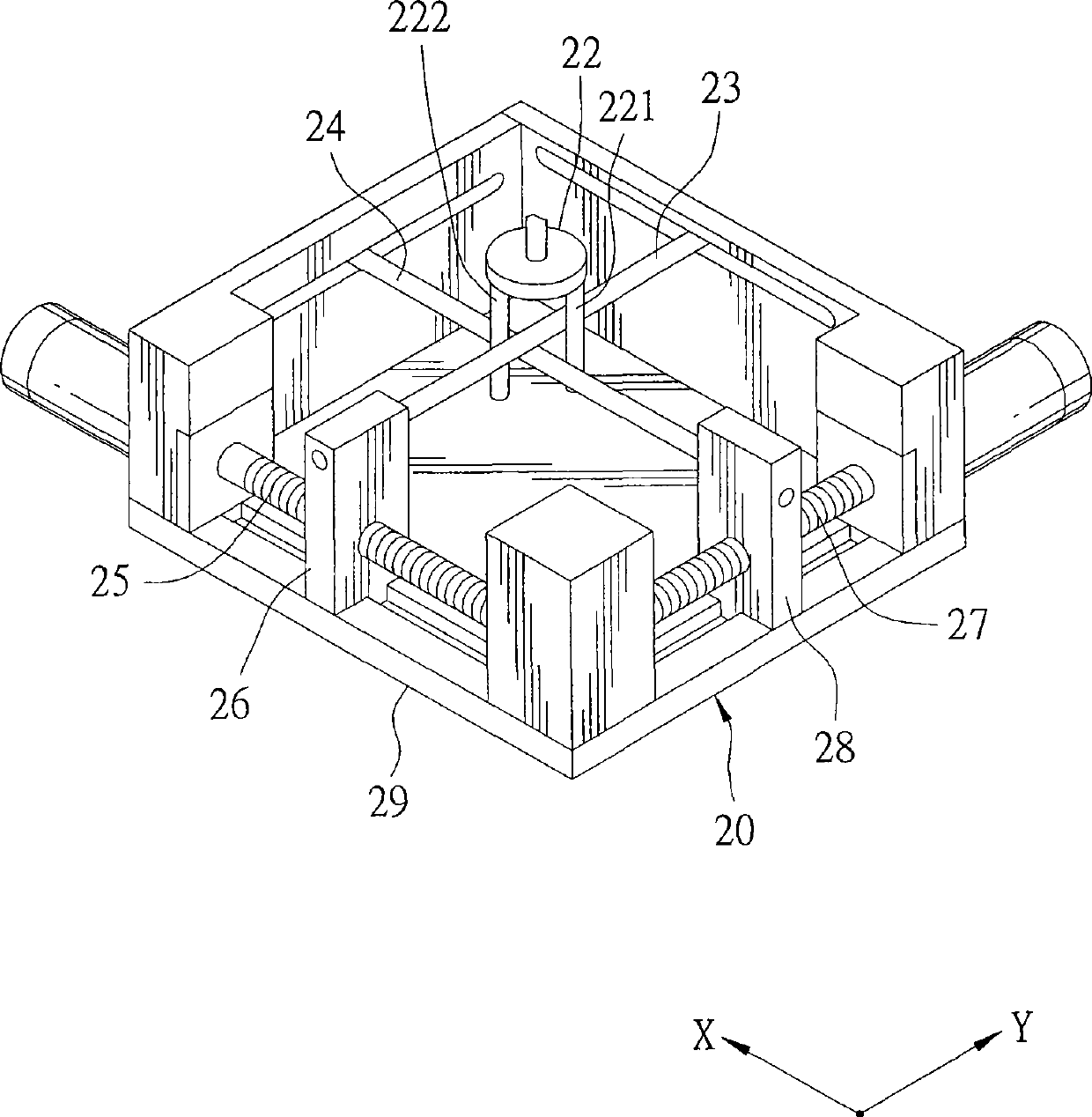

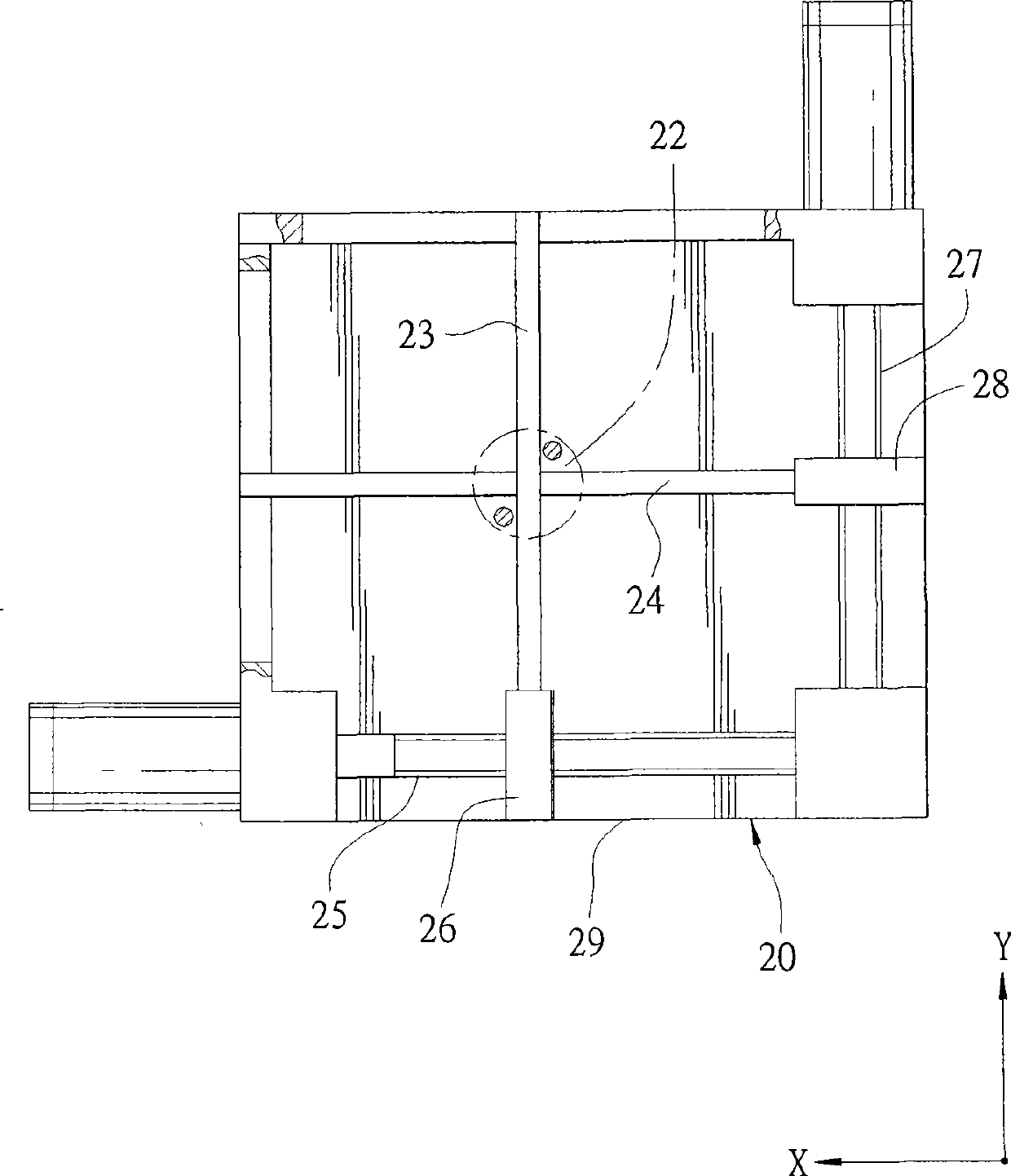

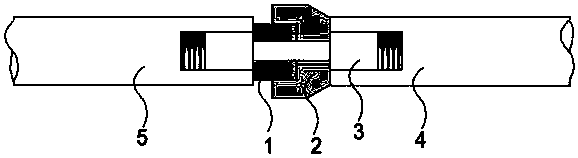

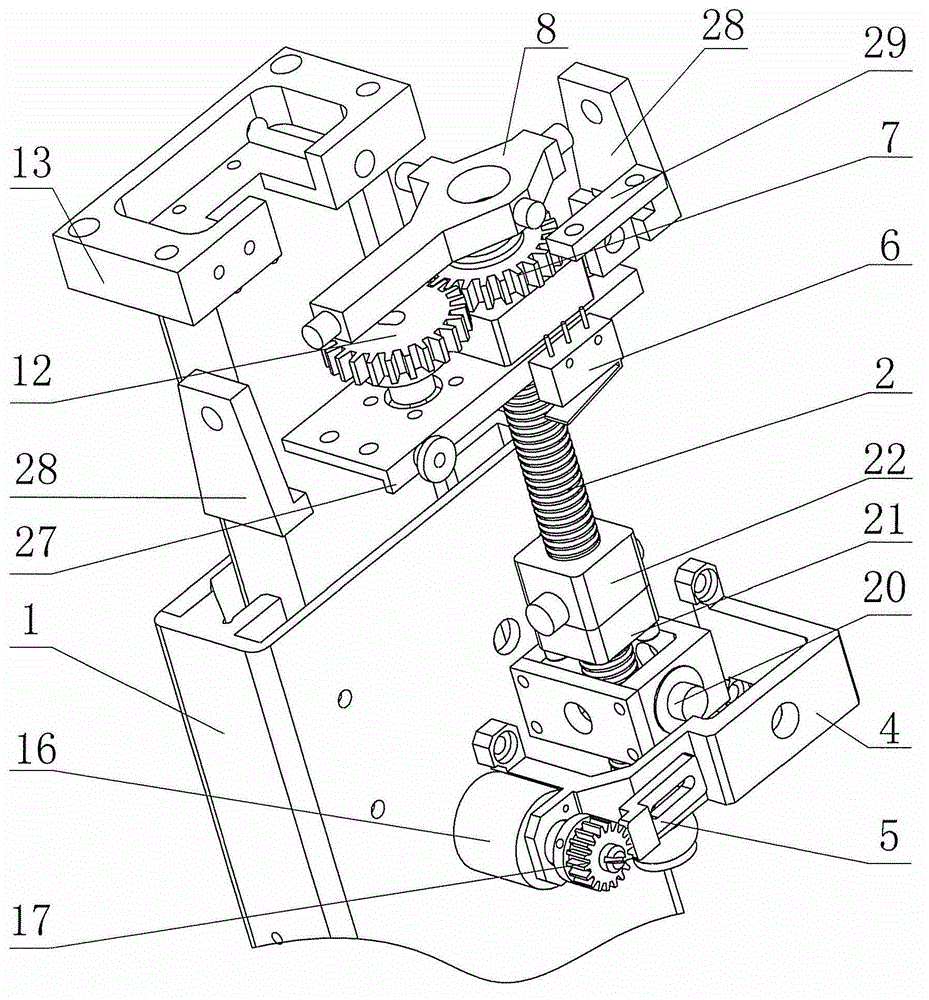

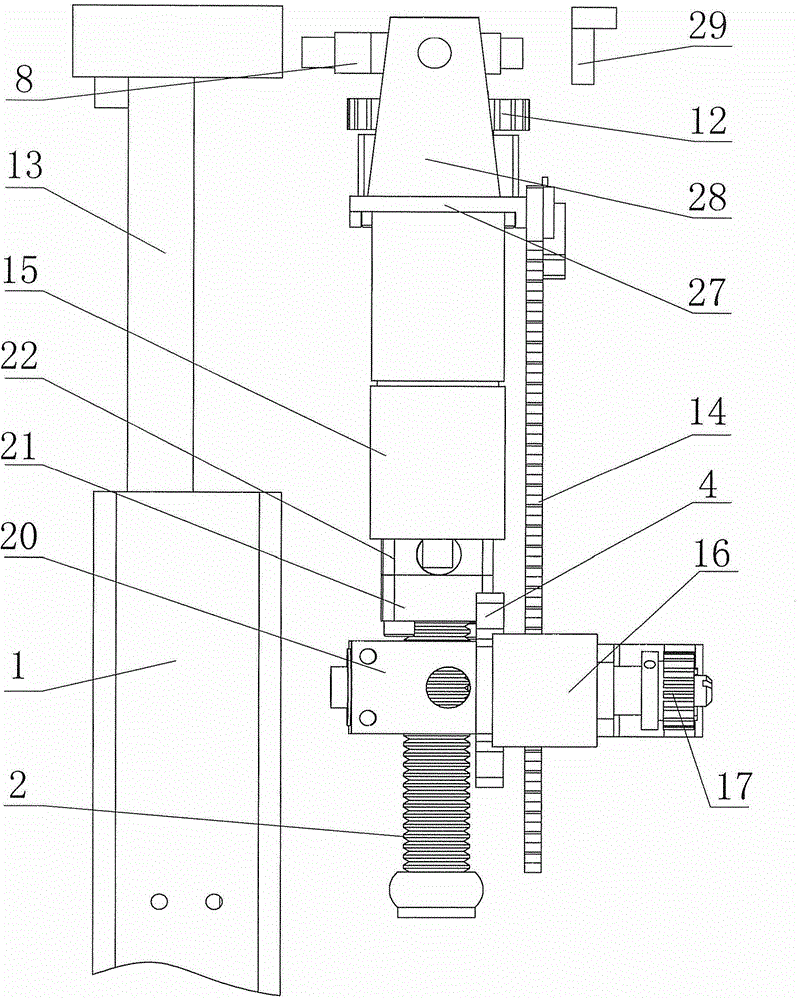

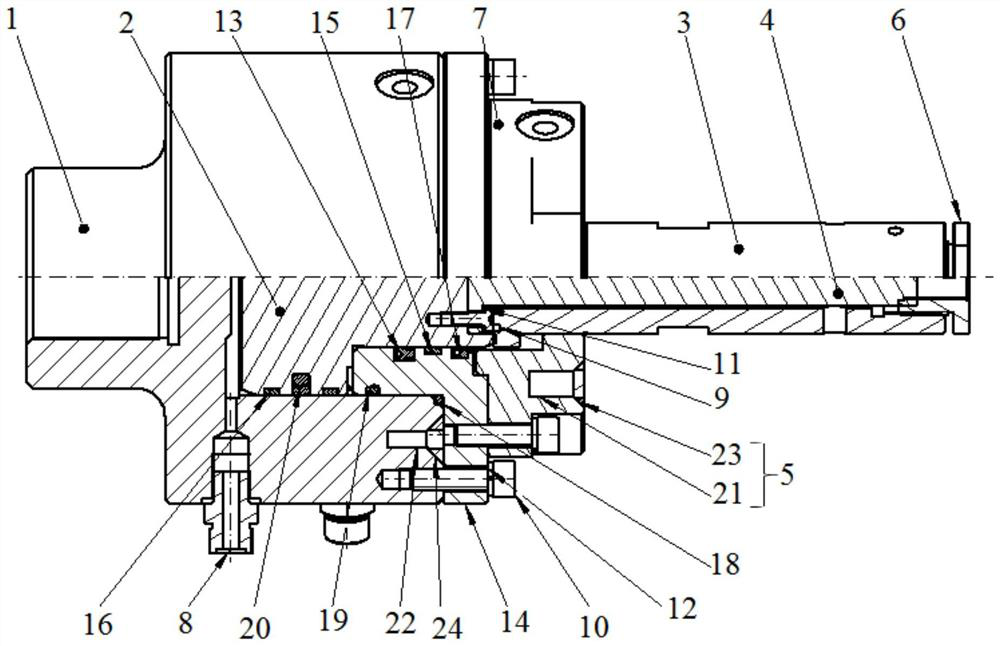

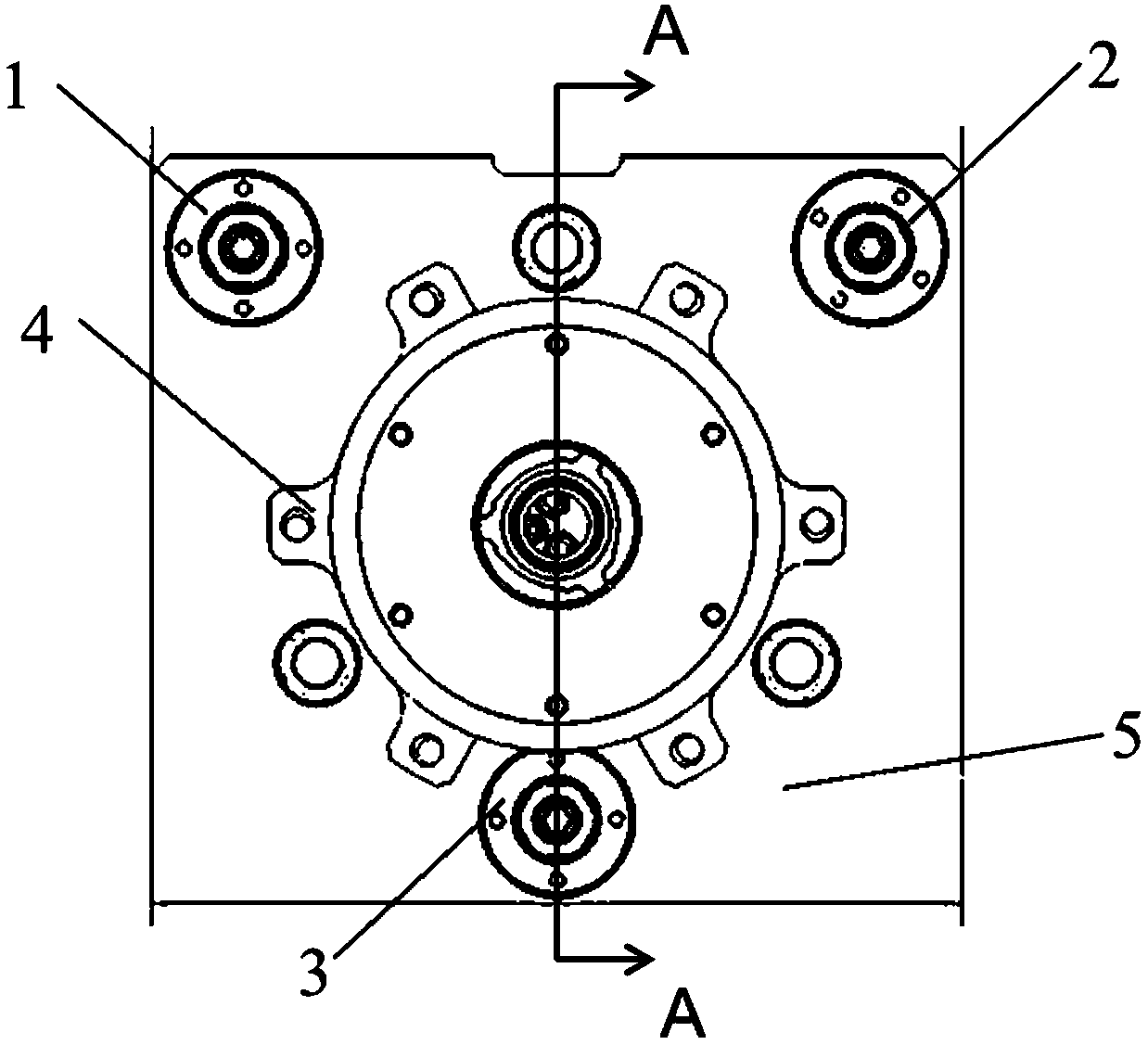

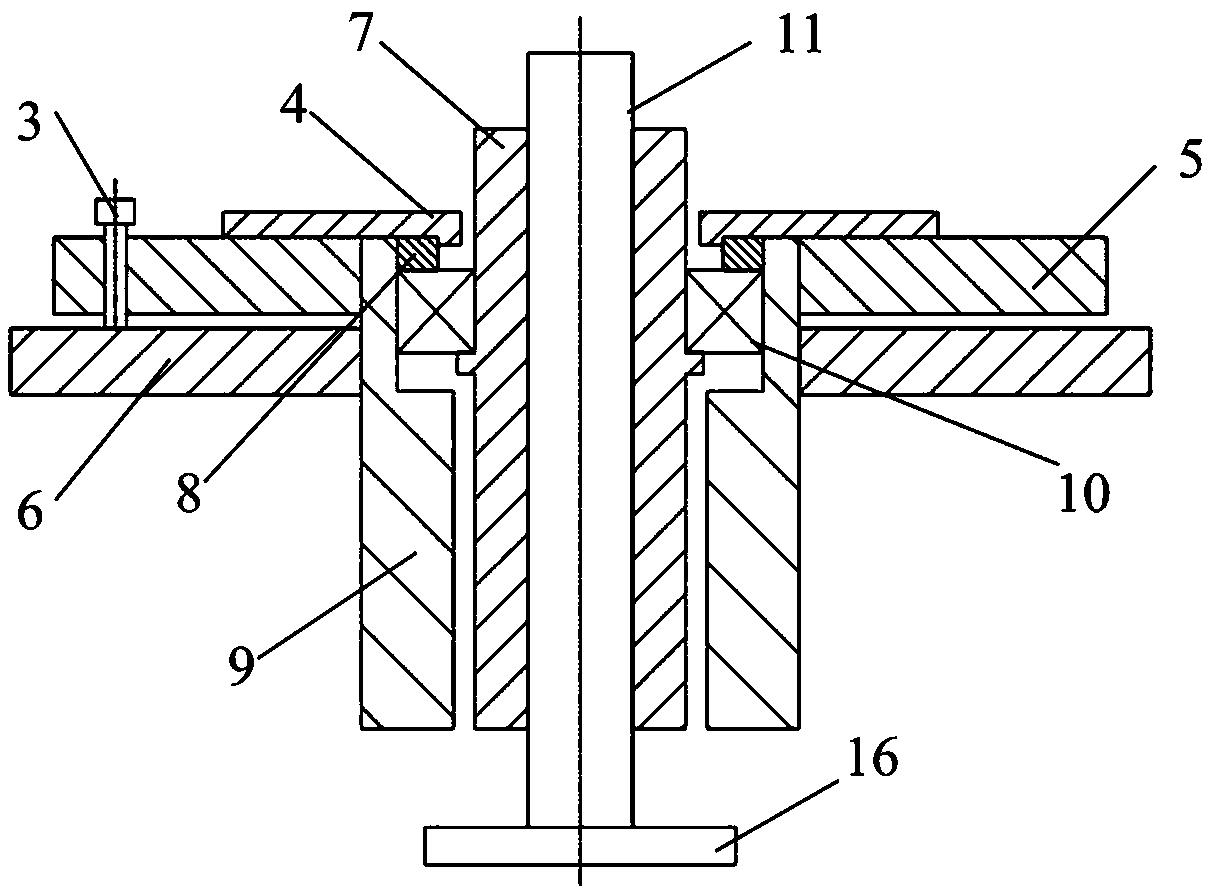

Automatic screw-driving machine with double electric screwdrivers and multiple feeders

InactiveCN105127730AImprove work efficiencyImprove assembly accuracyMetal working apparatusControl systemLocking mechanism

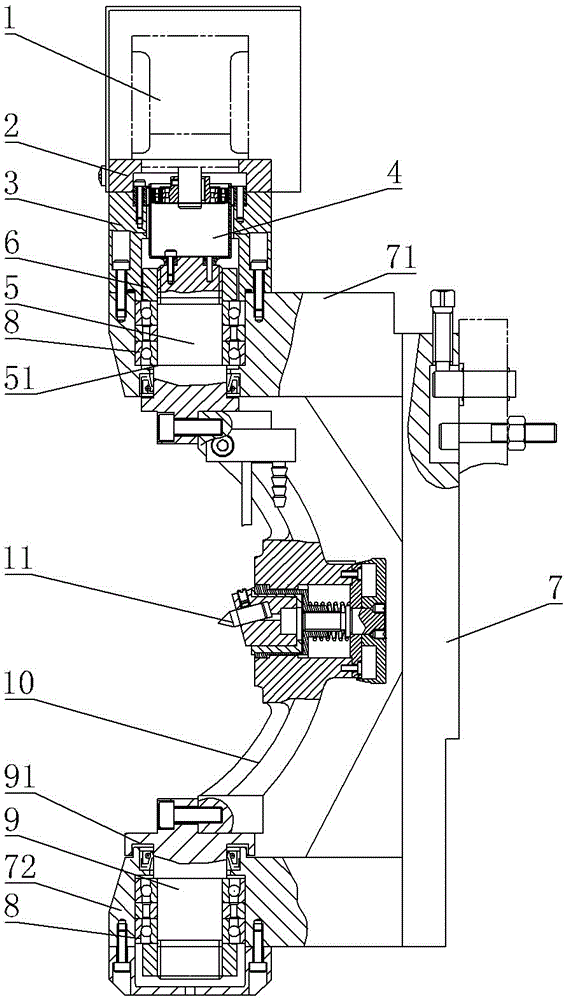

The invention discloses an automatic screw-driving machine with double electric screwdrivers and multiple feeders. The automatic screw-driving machine comprises a machine base; a Y-axis moving mechanism is arranged in the middle of the machine base and provided with two sets of clamps; a cross beam is arranged on the machine base and located above the middle of the Y-axis moving mechanism; at least two sets of symmetrical screw feeding mechanisms are arranged on the left and right sides of each of the head end and the tail end of the Y-axis moving mechanism; an X-axis moving mechanism is arranged on the cross beam, and two sets of locking mechanisms are arranged on the front and rear sides of the X-axis moving mechanism and are oppositely arranged; each set of locking mechanism comprises a locking fixing seat connected with the X-axis moving mechanism, and a Z-axis moving mechanism is arranged on each locking fixing seat and sequentially connected with a flexible device, one electric screwdriver, a screwdriver head and a suction nozzle component; a handheld type operation control system is arranged on one side of the cross beam. According to the automatic screw-driving machine, manual operation is replaced with an automatic mode, so that the work efficiency is improved, the production cost is lowered, operation is reliable, and the assembling precision is high.

Owner:NEW ROAD MARK AUTOMATION TECH

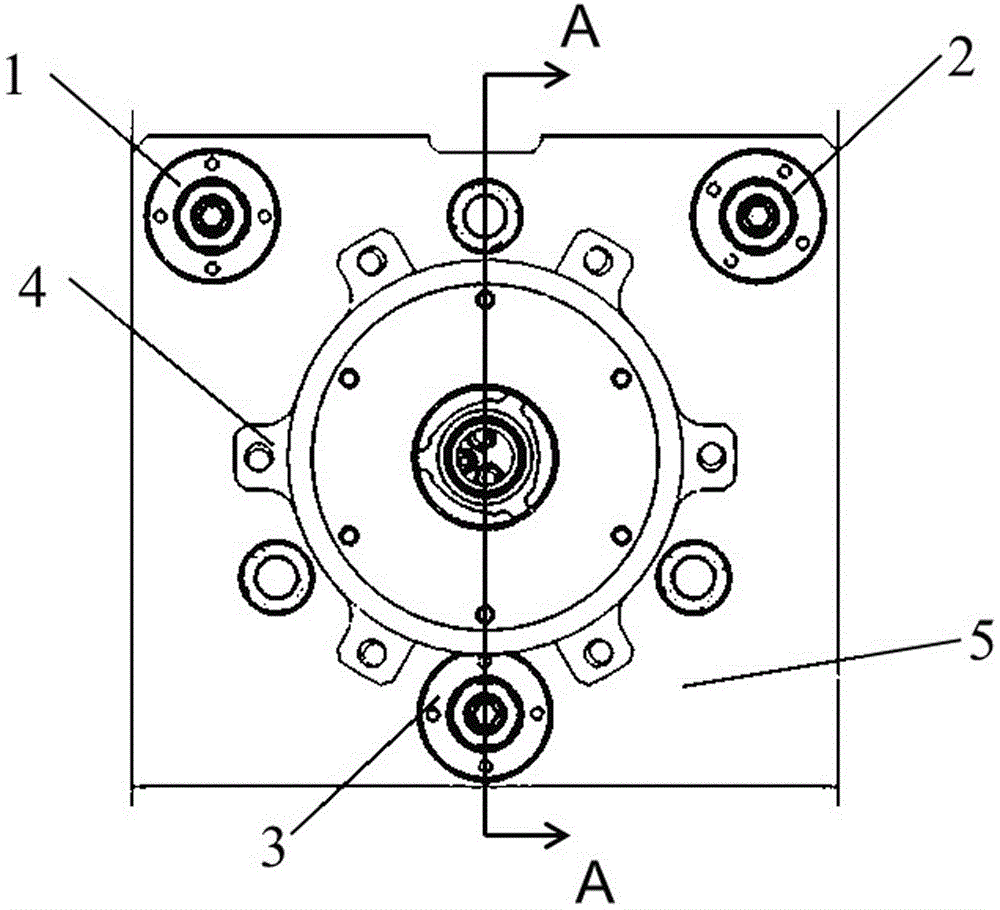

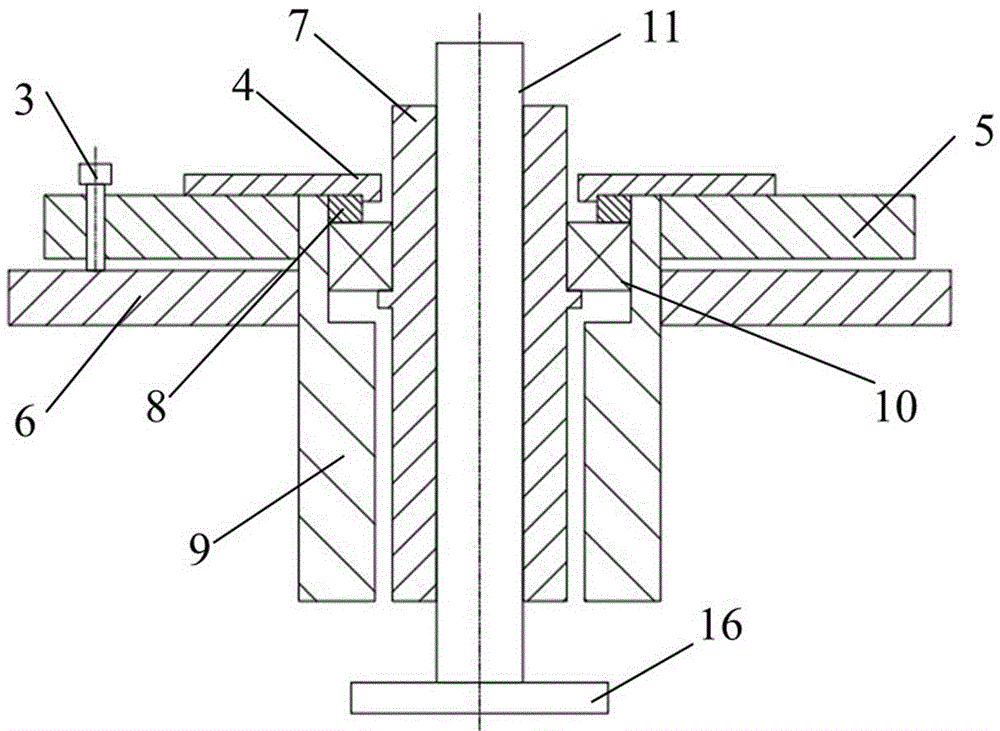

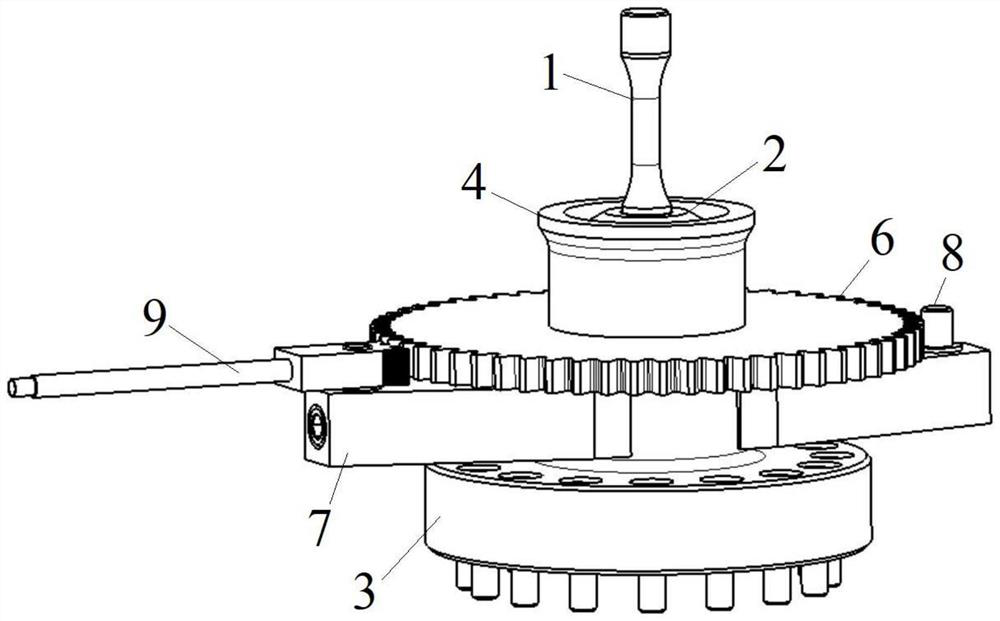

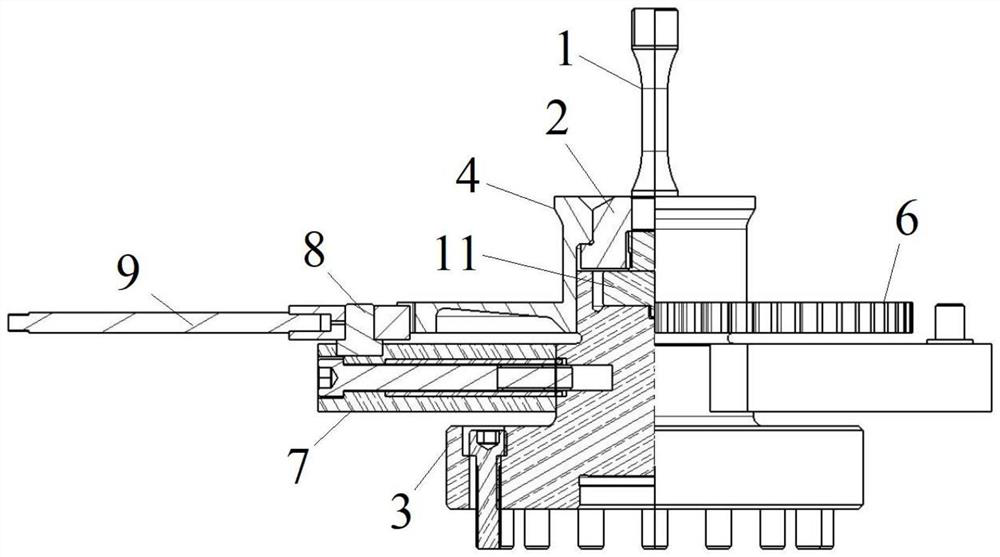

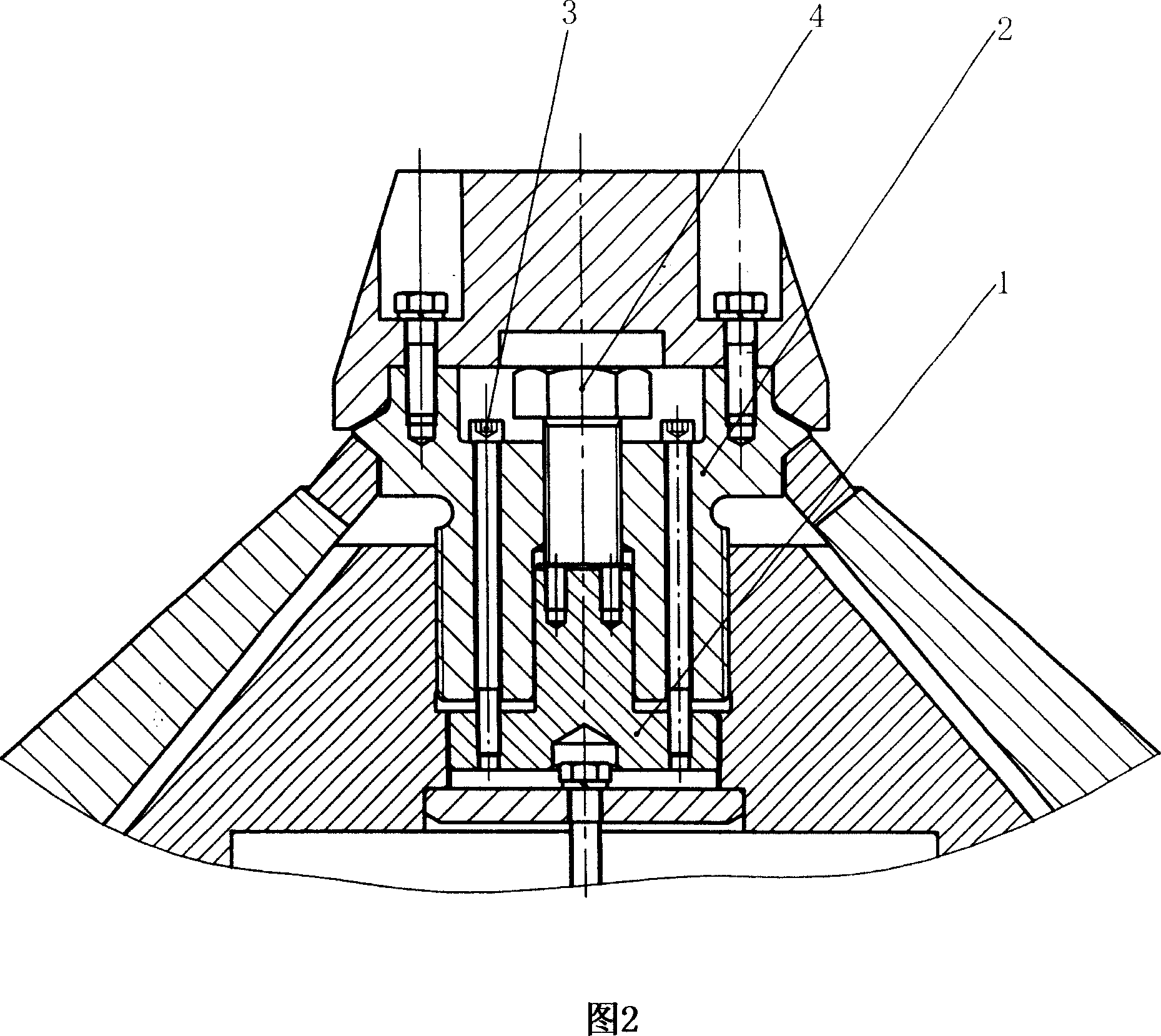

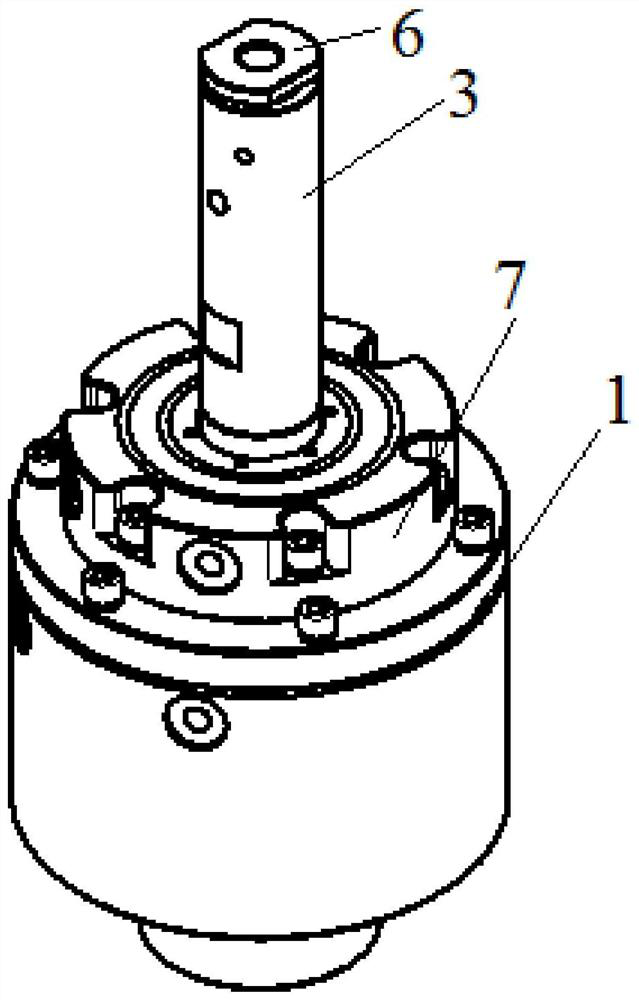

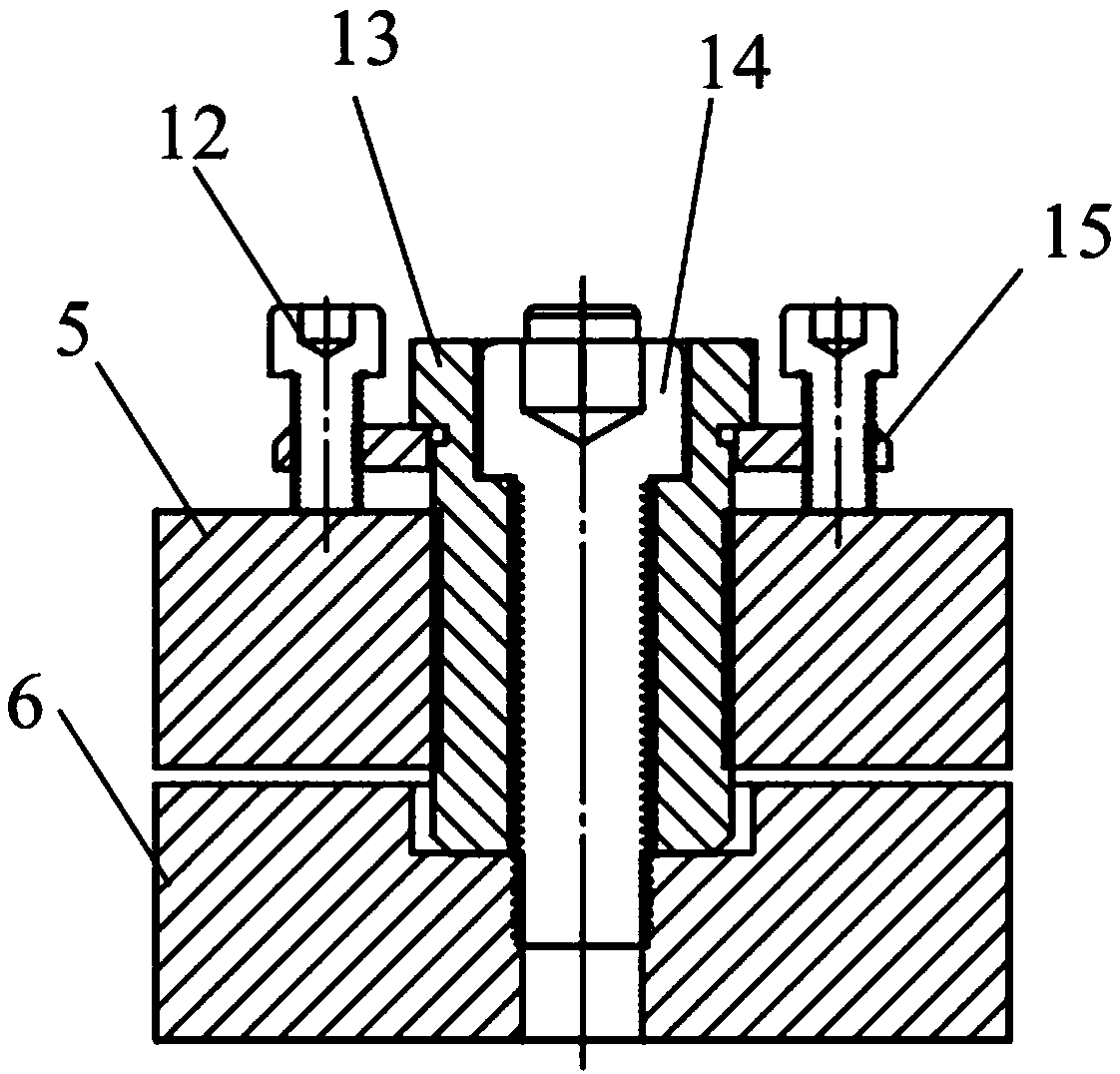

Levelling device and levelling method for polishing head

The invention discloses a levelling device and a levelling method for a polishing head. The levelling device comprises a spline shaft, a spline hub, a bearing sleeve, a bearing end cap, a bearing pre-tightening ring, a bearing, an adjusting panel, a base plate and at least three levelling screw sets; the adjusting panel is arranged on the upper surface of the base plate; the bearing end cap is matched with the bearing pre-tightening ring for pre-tightening the outer ring of the bearing; the bearing is arranged between the spline hub and the bearing sleeve; the spline shaft is accommodated in the spline hub; and each levelling screw set is connected onto the adjusting panel. According to the levelling device, levelling operation is transferred to the polishing head through the spline shaft, and the area of the polishing head is large, so that the polishing head is applicable to polishing of wafers with large sizes. Loosening-proof flanges are used for eliminating threaded clearances between levelling nuts and the adjusting panel; the levelling precision is improved; and the phenomenon that a pre-levelled position is changed by friction force during a process of rotating fastening bolts is prevented.

Owner:BEIJING SEMICORE PRECISION MICROELECTRONICS EQUIP CO LTD

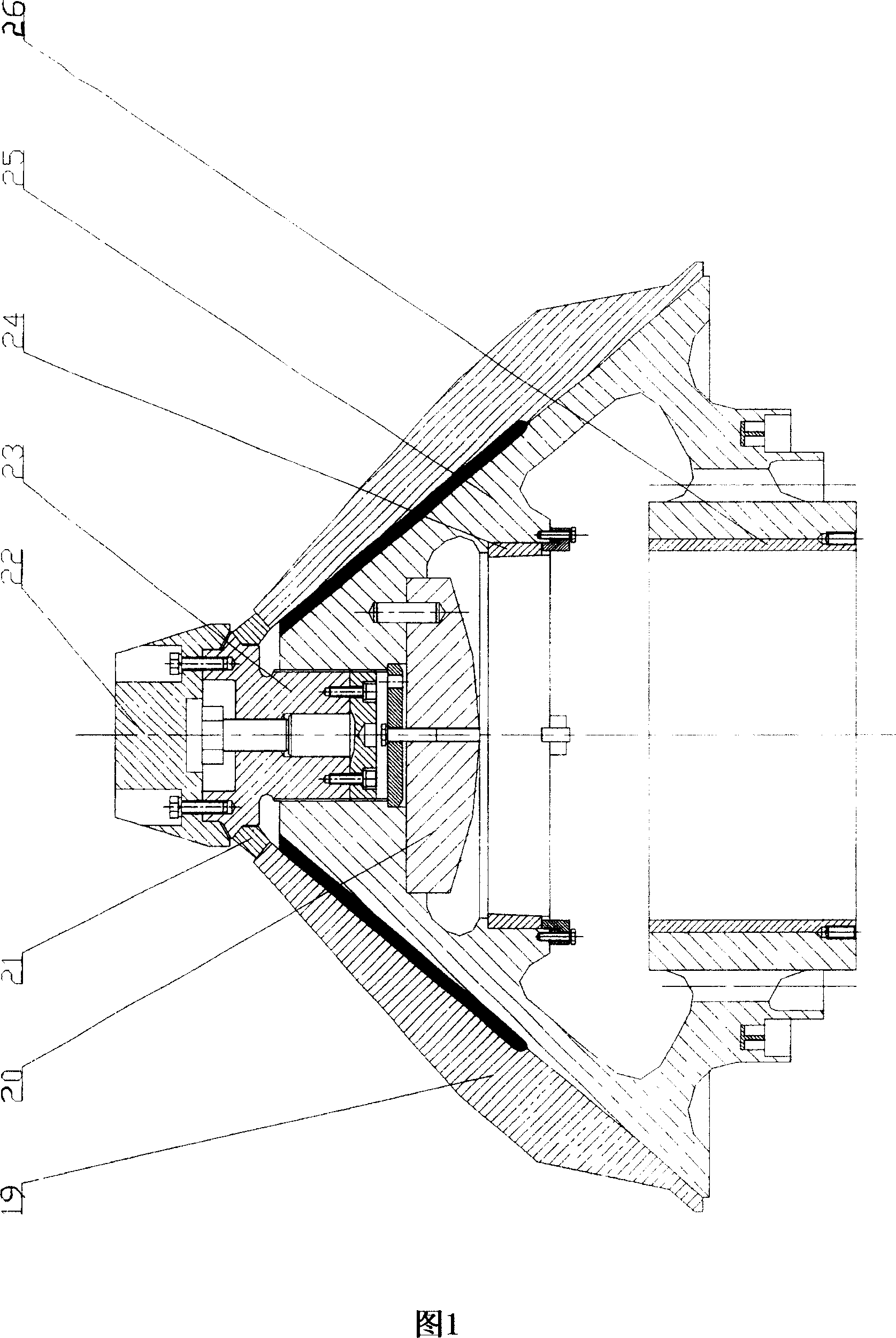

High temperature tensile fatigue test fixture for panel test piece and method

ActiveCN106840867AStable clampingAchieving Stretch FatigueMaterial strength using tensile/compressive forcesTensile fatigueTest fixture

The invention discloses a high temperature tensile fatigue test fixture for a panel test piece and a method. The clamping for the panel test piece in a high temperature test is realized, so that the tensile fatigue test for the panel test piece can be performed under a high temperature condition. A hydraulic chuck of a fatigue machine is used for clamping an optical rod end of a central shaft and is connected with a connecting rod through a sleeve; a fixing nut is arranged on the central shaft; the fixing nut is used for limiting the downward movement of the sleeve; the connecting rod is fixed with the sleeve through a screw; the connecting rod is in threaded connection with a wedge-shaped chuck body; the central shaft passes through a through hole in the middle of the connecting rod; a shaft end is connected with a guiding platform; the guiding platform is located in a groove between two wedge-shaped clamp blocks and is used for guiding the wedge-shaped clamp blocks to move up and down; the test piece is clamped by the wedge-shaped clamp blocks in the wedge-shaped chuck body; the bottoms of the wedge-shaped clamp blocks are propped by the top end of the guiding platform; the two sides are in contact with the wedge-shaped plane in the wedge-shaped chuck body; the upwards movement of the wedge-shaped clamp blocks is limited. The high temperature tensile fatigue test fixture can meet the requirement for stably clamping the panel test pieces in various sizes and can realize the single-shaft tensile fatigue under the high temperature condition.

Owner:BEIHANG UNIV

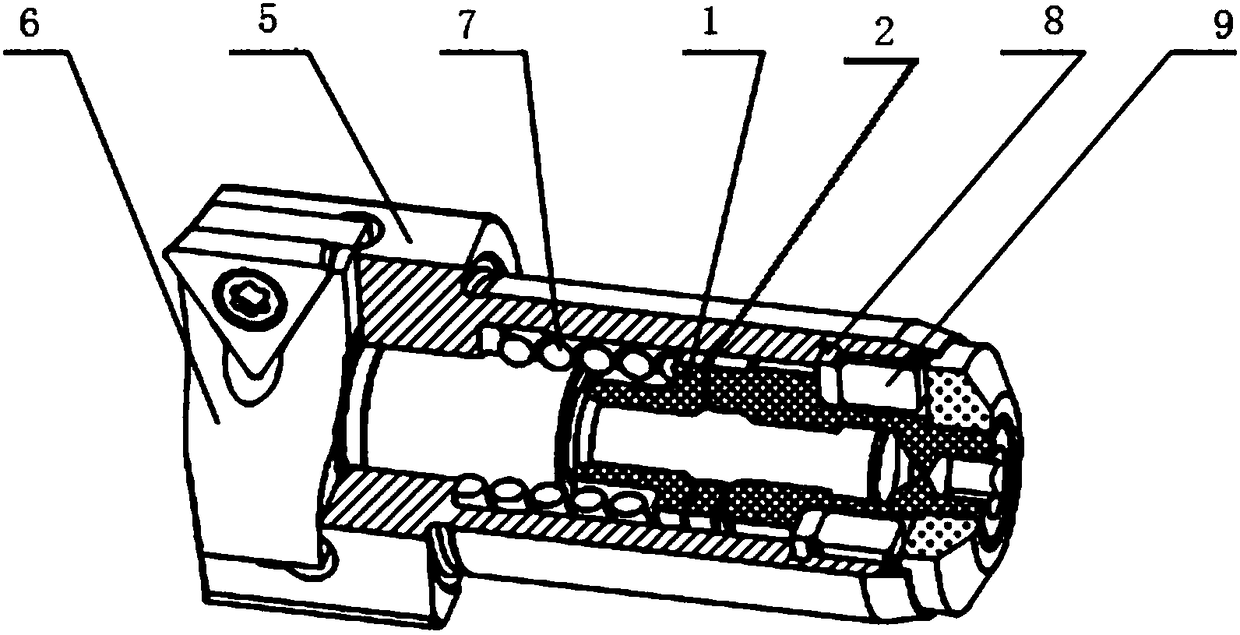

Grinding wheel dresser for grinding machine

InactiveCN106346366AQuick trimEasy to trimAbrasive surface conditioning devicesSteel ballEngineering

The invention provides a grinding wheel dresser for a grinding machine, which aims at solving the technical problems of poor universality and waste of processing time and labor in the existing grinding wheel dresser. The grinding wheel dresser comprises a diamond pen base, a swing rod, a machine base and a driving device, wherein a diamond pen is arranged on the diamond pen base; both ends of the swing rod are rotationally supported at both ends of the machine base; the driving device is used for driving the swing rod to rotate. The grinding wheel dresser is characterized in that a shaft hole is formed in the swing rod, a slide sleeve is arranged in the shaft hole, and the diamond pen base is inserted into the slide sleeve; slide blocks are arranged at both radial ends of the inner side of the shaft hole and extend in the axial direction, both radial ends of the slide sleeve are provided with slide grooves which are matched with the slide blocks, the two sides of each of the slide blocks and the slide grooves are provided with arc-shaped grooves, and steel balls fill the opposite arc-shaped grooves; a thread sleeve is arranged at the tail part of the slide sleeve, and is connected with an adjusting rod through threads, the adjusting rod is parallel with the axis of the shaft hole, an end cover is covered at the tail part of the shaft hole, the adjusting rod penetrates through the end cover and is vertically and fixedly connected with a dial, a spring is sheathed on the thread sleeve, and both ends of the spring are respectively abutted against the slide sleeve and the end cover.

Owner:WUXI MACHINETOOL

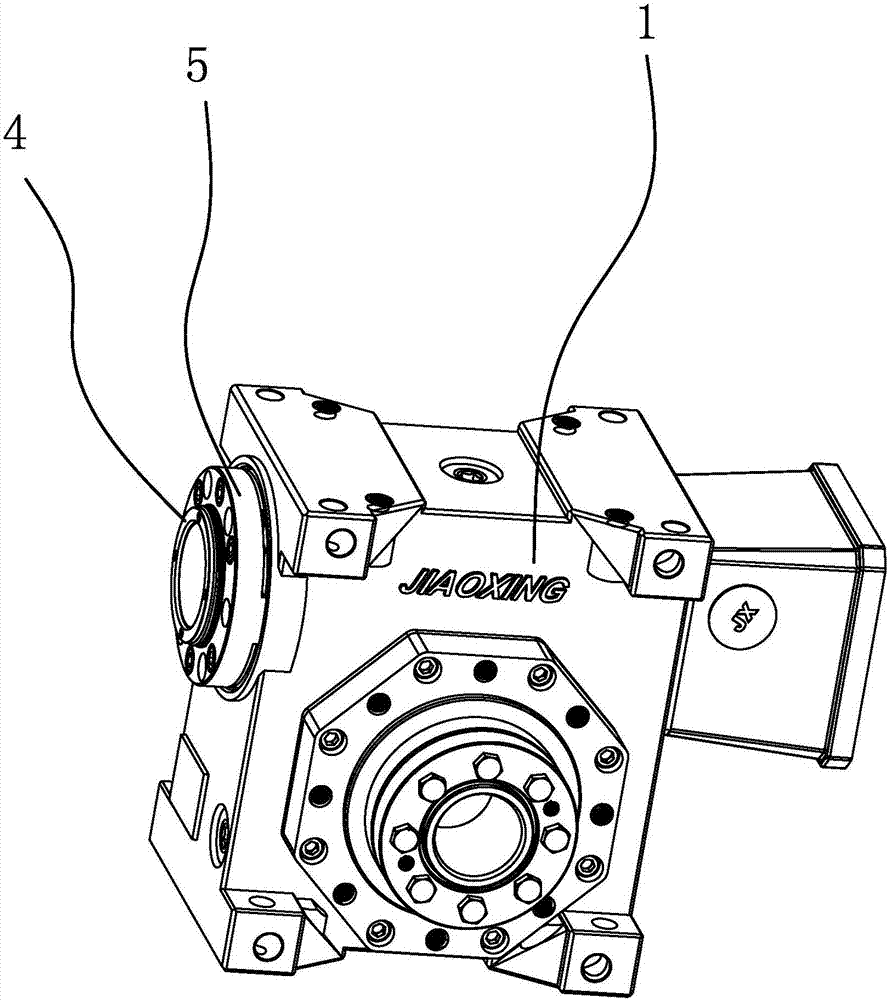

Worm gear reducer

PendingCN107504133AHigh adjustment accuracyReduce wearToothed gearingsGearing detailsReduction driveScrew thread

The invention provides a worm gear reducer, belongs to the technical field of mechanisms, and aims at solving the problems of poor adjusting accuracy and liable abrasion of an existing worm gear reducer. The worm gear reducer comprises a housing which is provided with a shaft hole, a worm gear, a worm, an adjusting sleeve, a locking sleeve and a first locking bolt, wherein the adjusting sleeve is connected into the locking sleeve through threads; the locking sleeve is arranged at the end part, close to the output end of the worm, of the housing; the output end of the worm is axially fixed into the adjusting sleeve; the inner end of the locking sleeve is arranged in the shaft hole by sliding and penetrating, and the outer end of the locking sleeve is provided with a convex annular convex edge part; a bolt rod of the first locking bolt penetrates through the annular convex edge part to be connected to the housing through the threads; the annular convex edge part is compressed to the housing through a head part of the first locking bolt. According to the worm gear reducer, the locking sleeve and the adjusting sleeve are matched in a pressing and pushing manner, so that thread gaps between the locking sleeve and the adjusting sleeve can be removed; the thread gaps in the first locking bolt are nearly ignored; the adjusting accuracy is high, and thus the abrasion of the worm gear can be reduced.

Owner:台州椒星传动设备有限公司

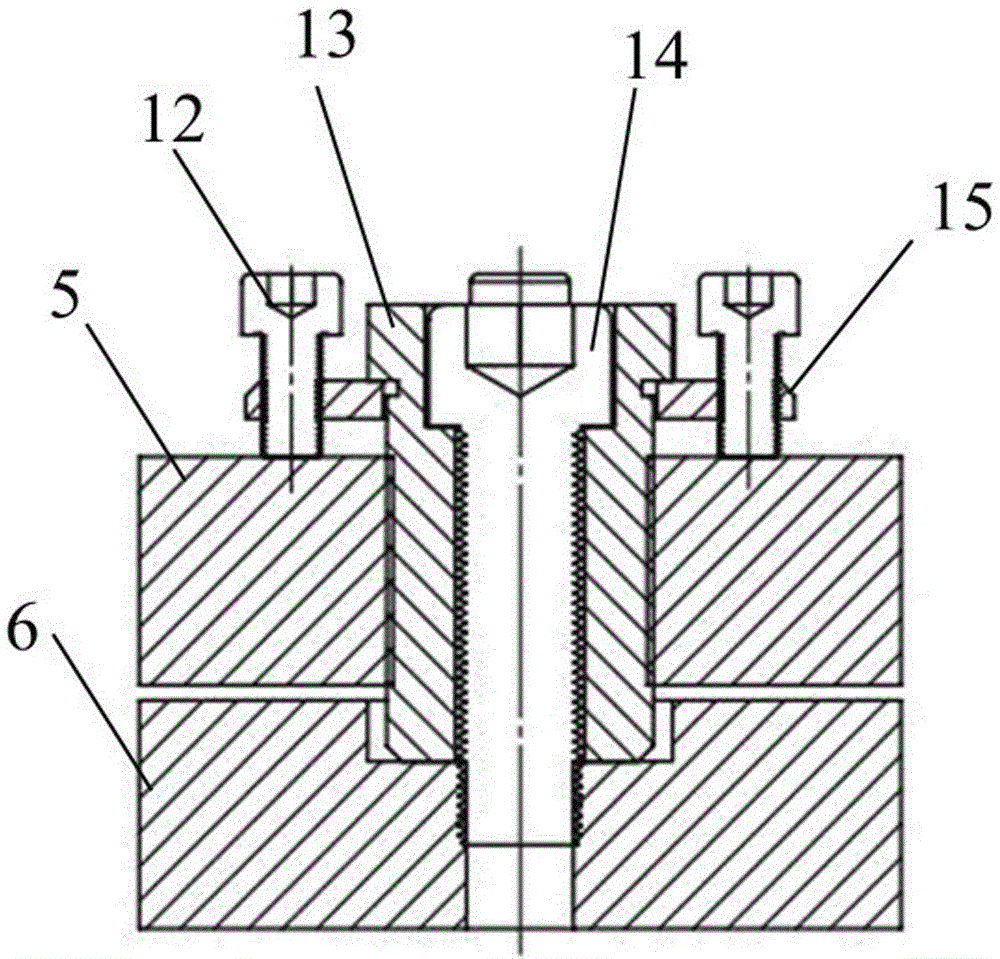

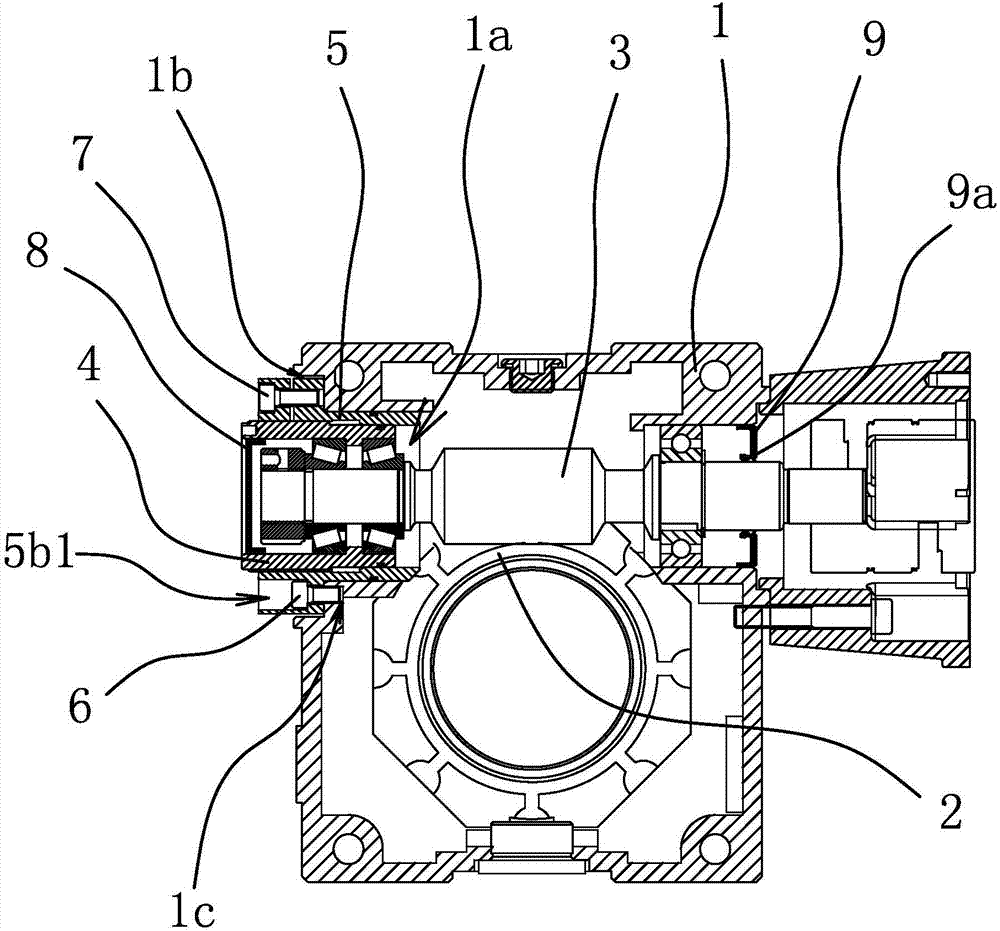

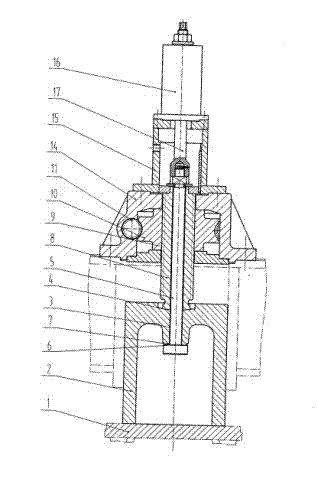

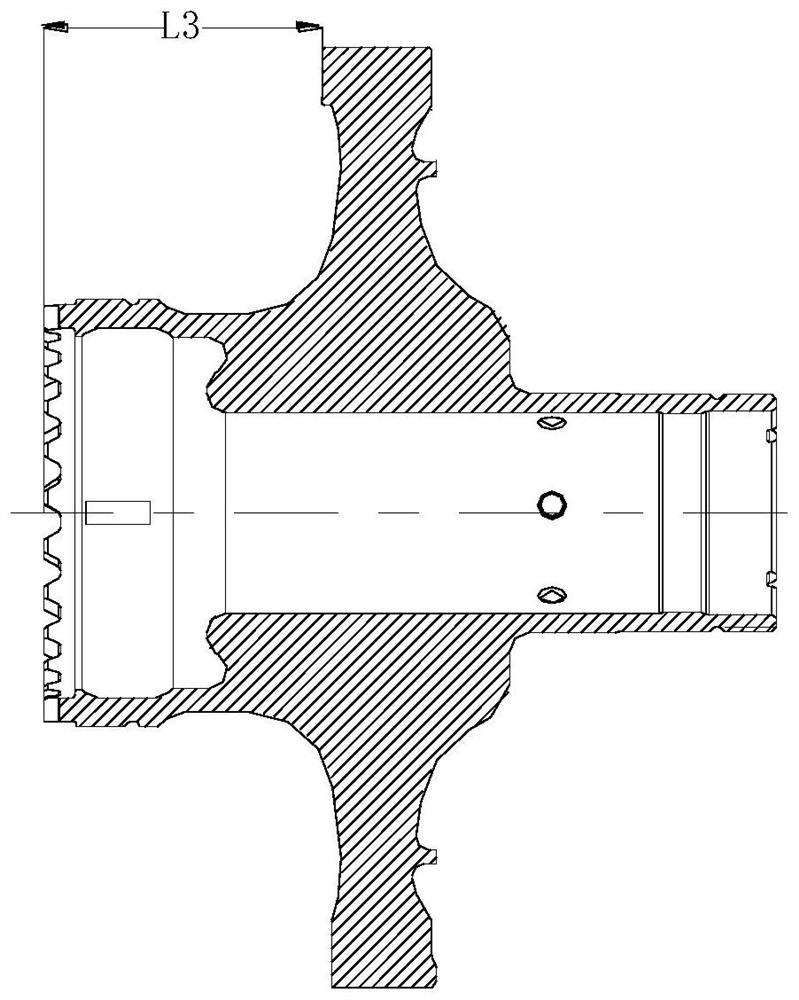

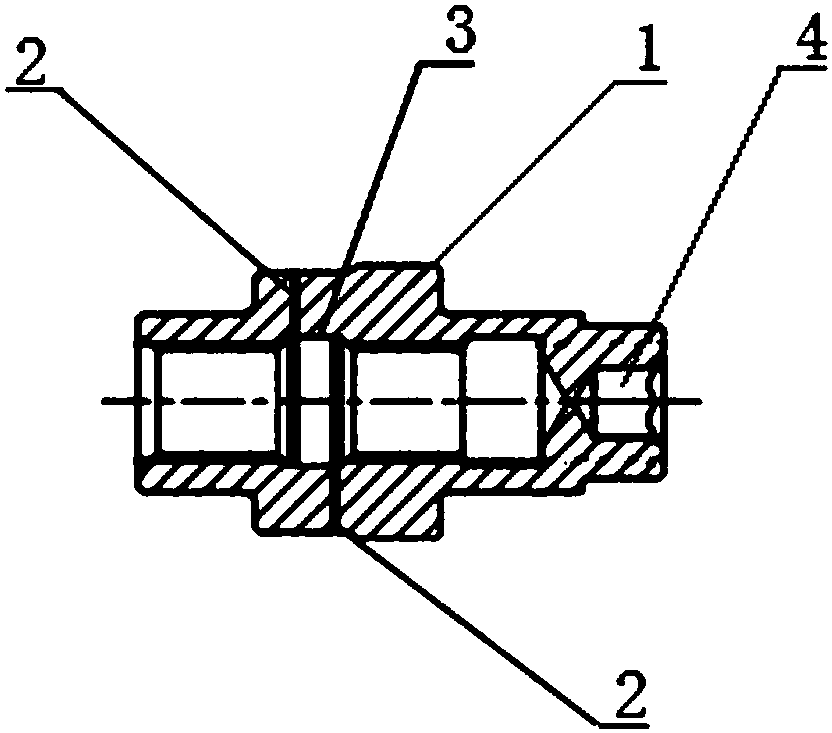

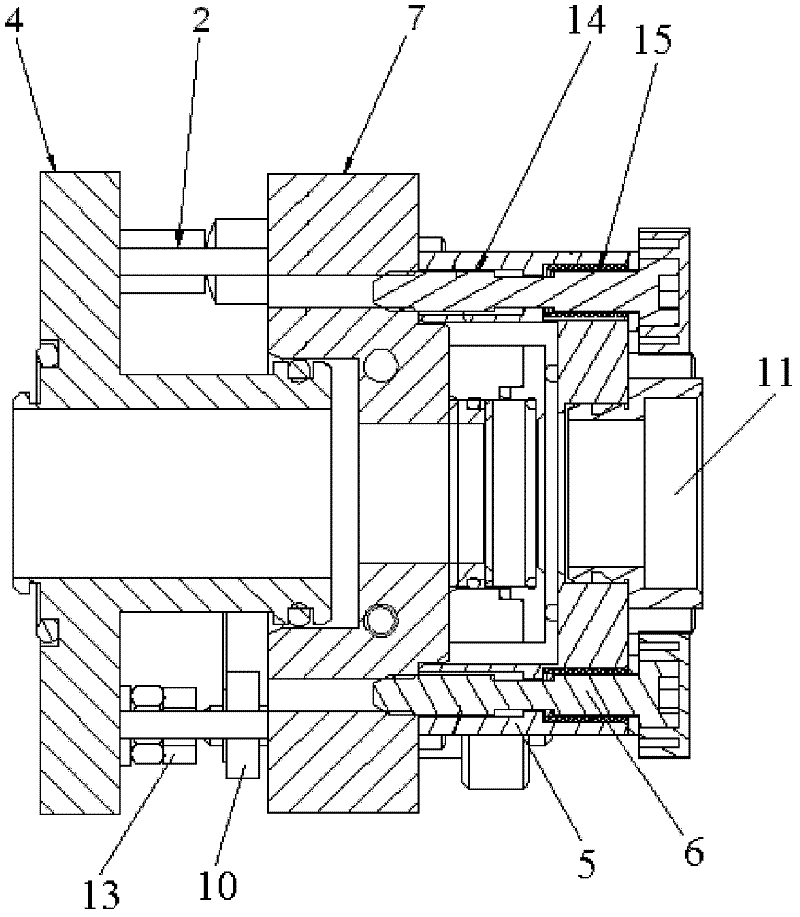

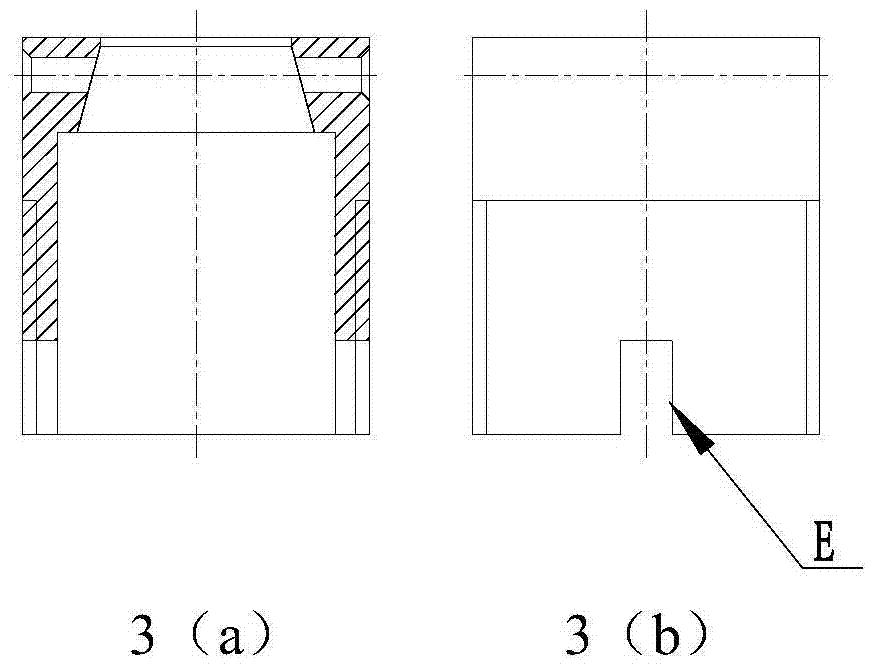

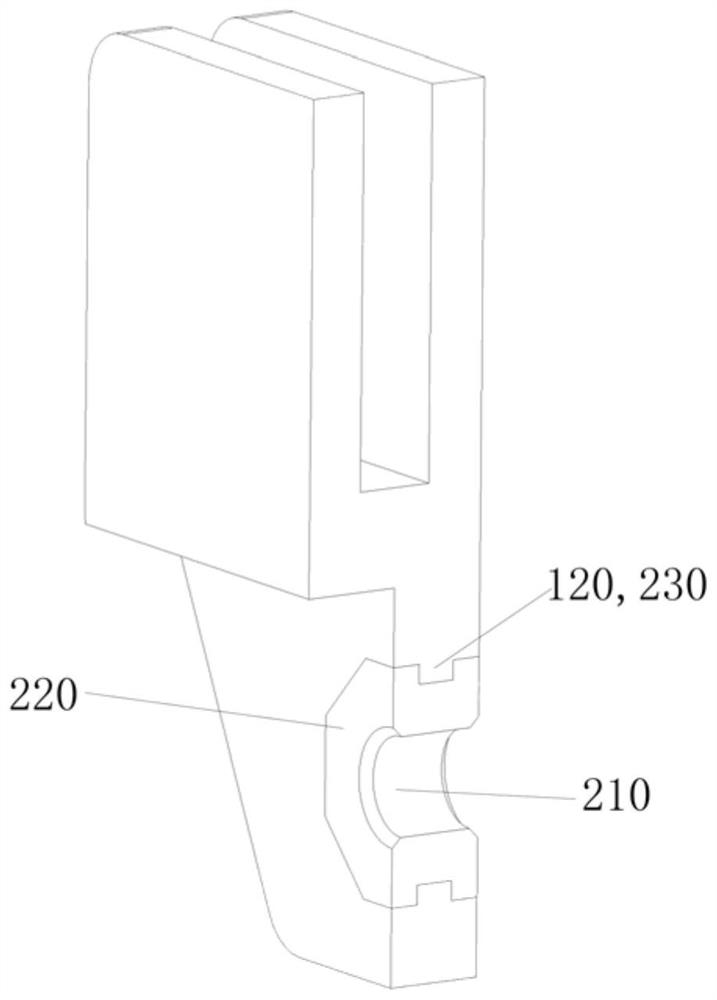

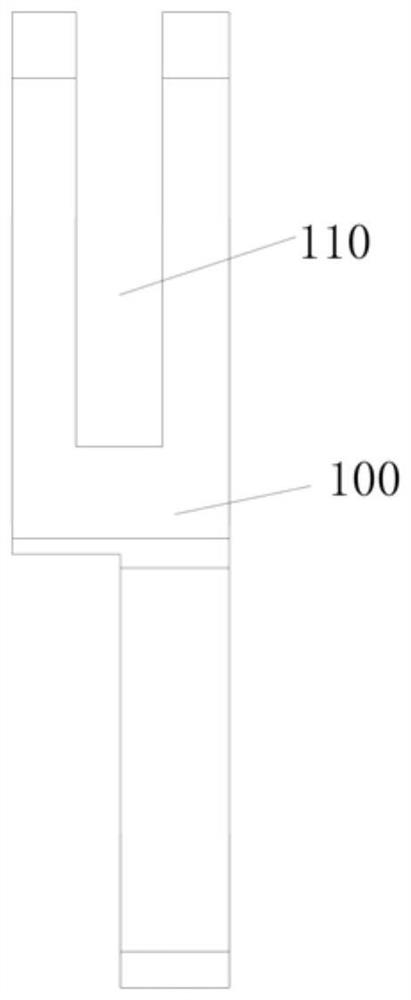

Hydraulic locking device of pressure machine

InactiveCN104723601AEliminate thread clearanceHigh precision of screw movementPressesEngineeringLocknut

The invention discloses a hydraulic locking device of a pressure machine. The hydraulic locking device of the pressure machine comprises a connecting rod with a stepped hole, a locknut installed on the stepped hole, and a screw located in the stepped hole, the screw can stretch out of the stepped hole in the length direction, a screw ball head is formed at the stretching end of the screw and connected with a sliding block, the top plane of the locknut has a certain axial clearance relative to a step, the screw and the locknut have a certain thread clearance when screwed together, and the axial clearance is larger than the thread clearance. A seal end cover with a radial through hole is installed on the bottom end face of the connecting rod, an axial separation cavity is formed between the seal end cover and the locknut and communicated with the radial through hole, and when hydraulic oil is injected into the radial through hole and the axial separation cavity is filled with the hydraulic oil, the screwed section of the locknut and the screw rod has elastic deformation. By the adoption of the technical scheme, the thread clearance can be eliminated, the screw is high in movement precision and long in service life, the precision of the sliding block moving to a bottom dead centre working position is improved, and therefore a stamped workpiece has high quality and precision.

Owner:浙江嚞锻机床有限公司

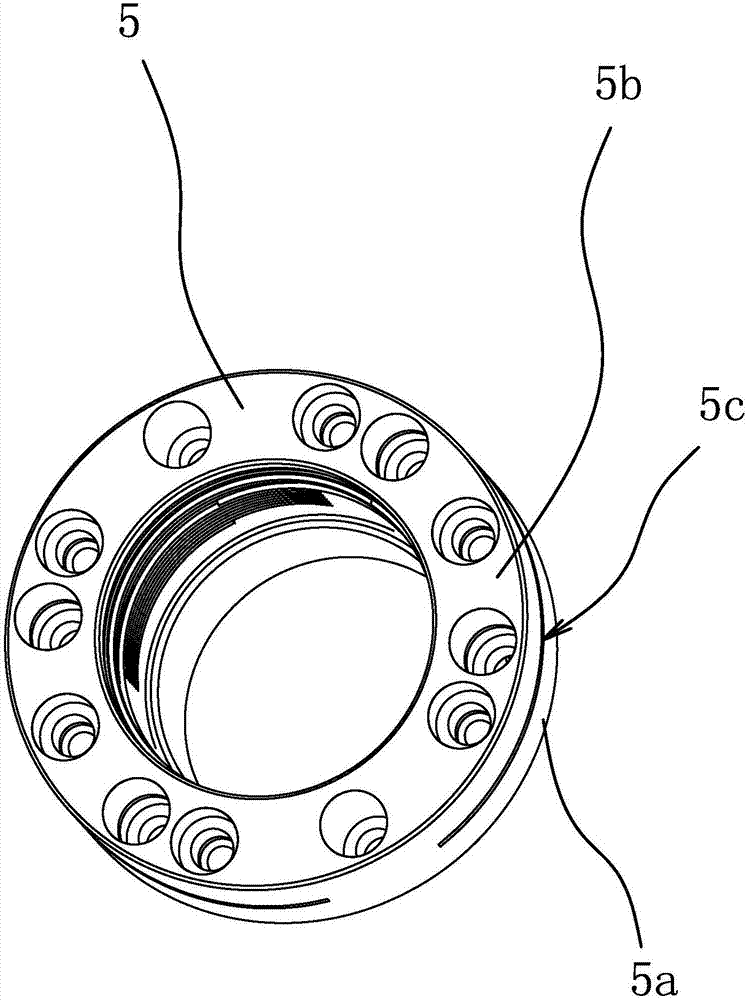

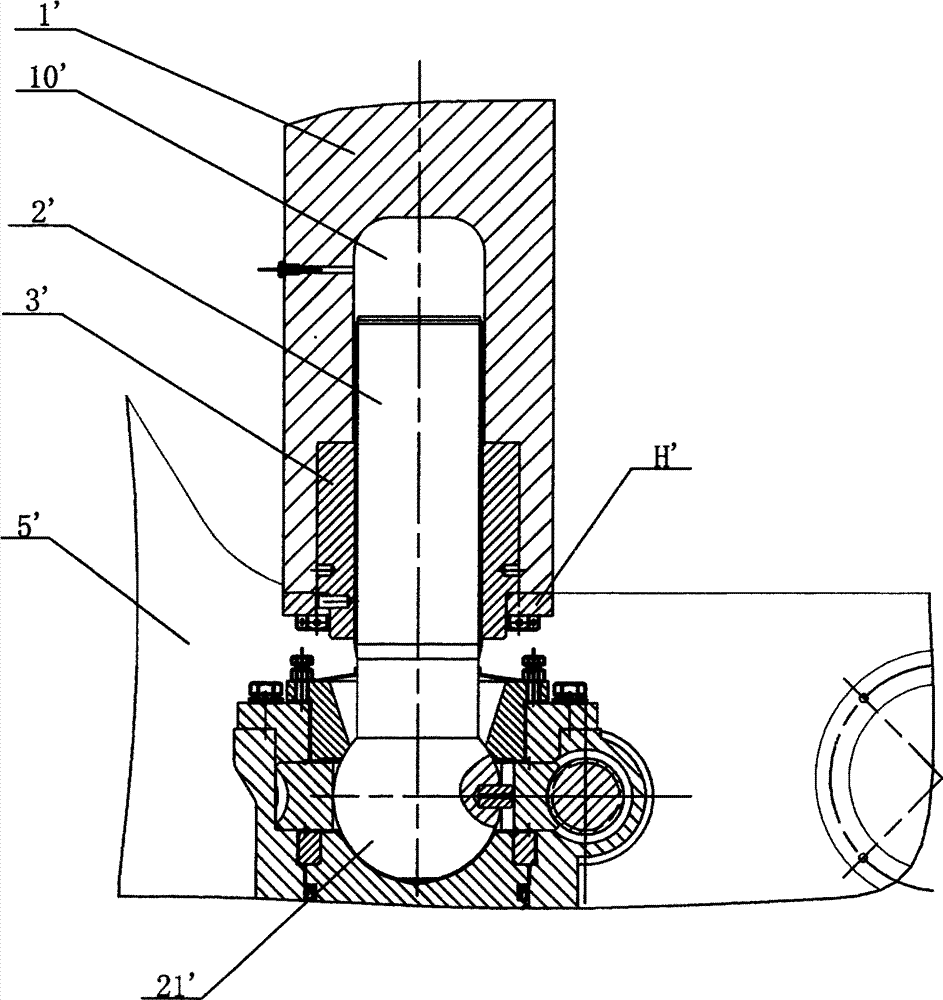

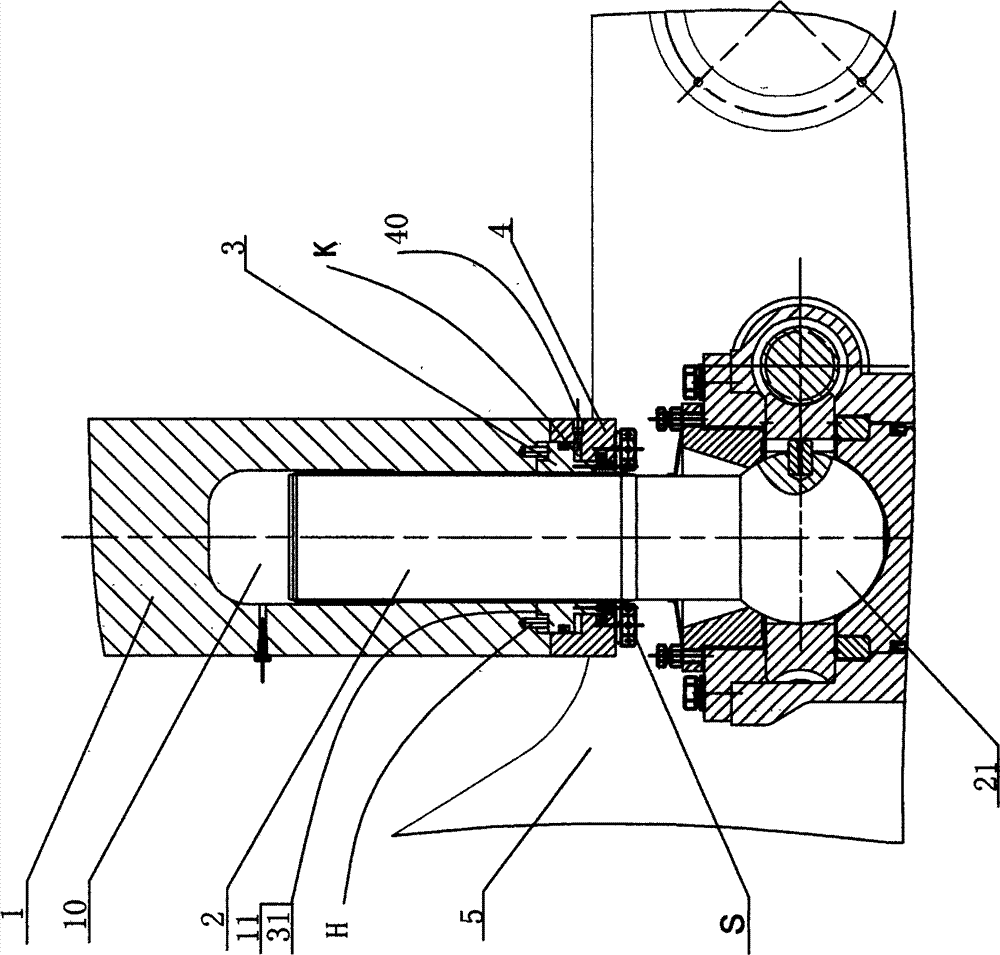

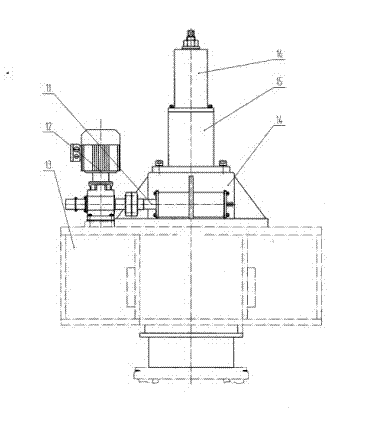

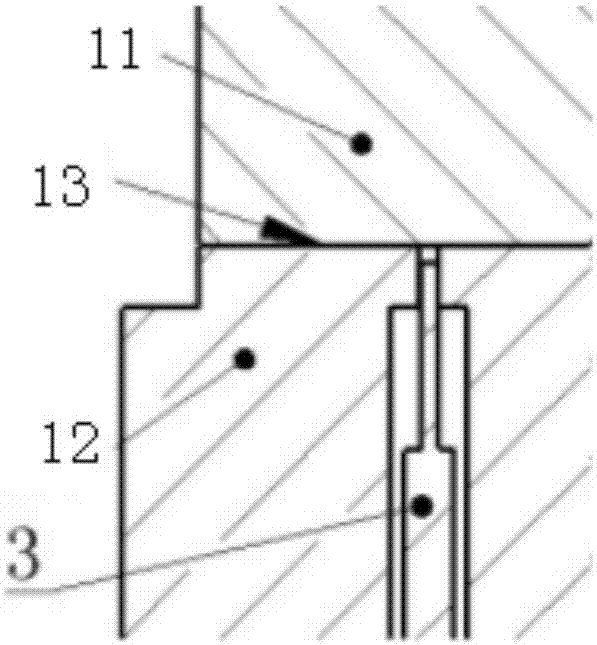

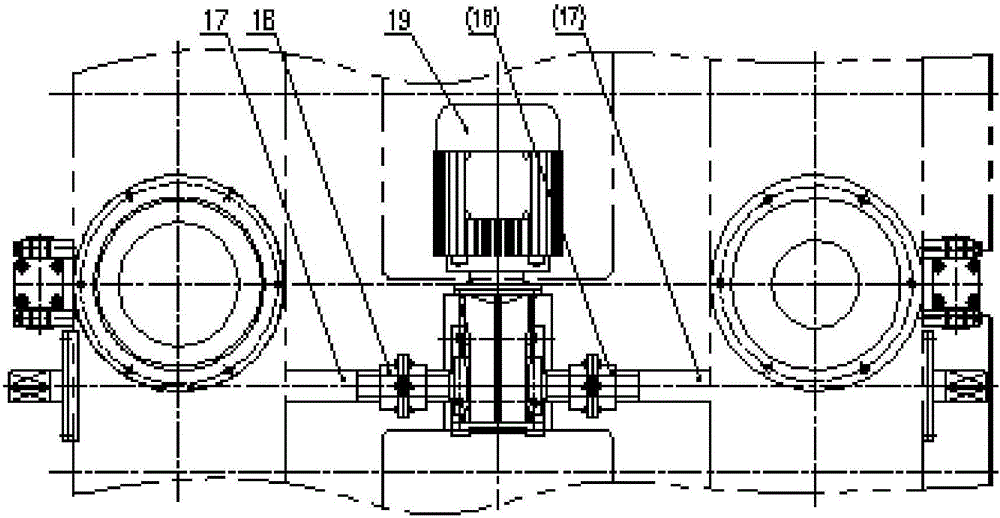

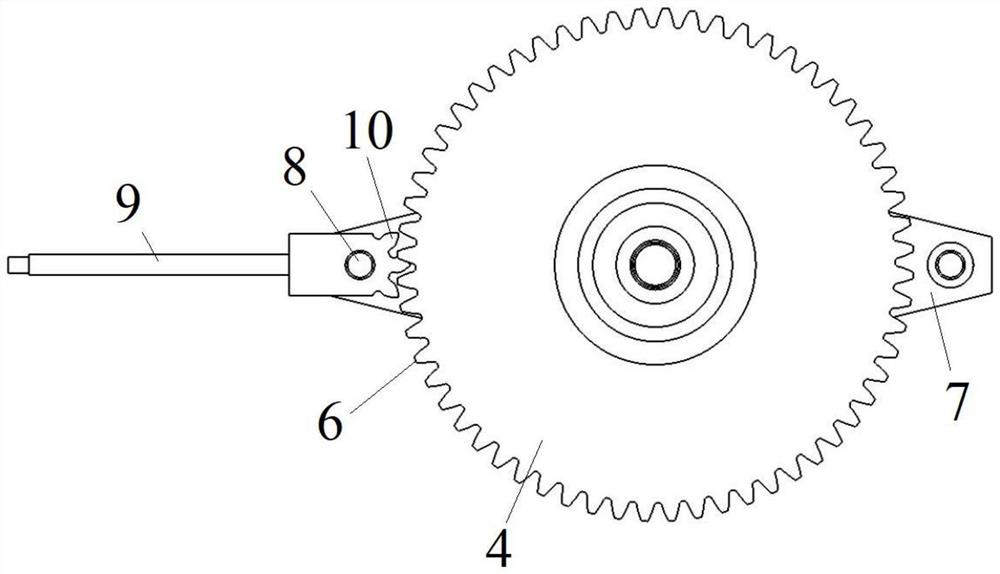

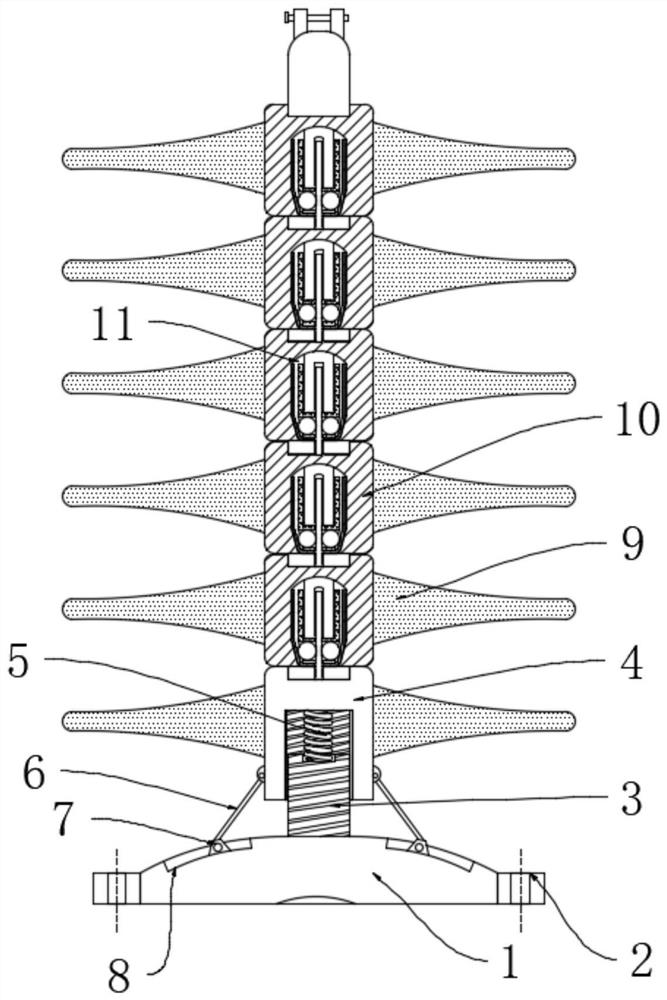

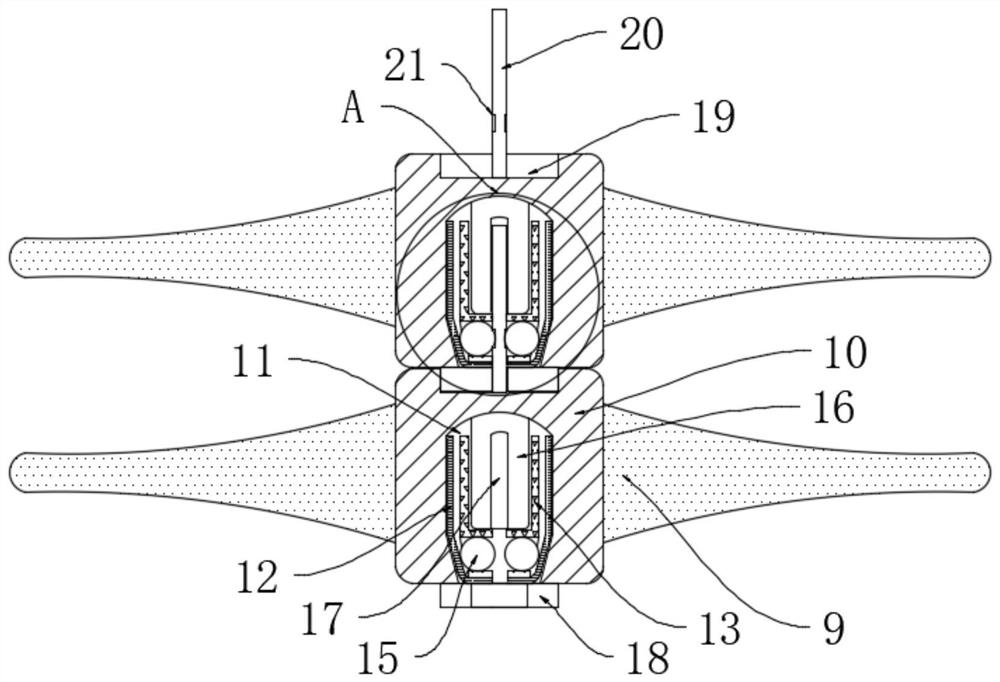

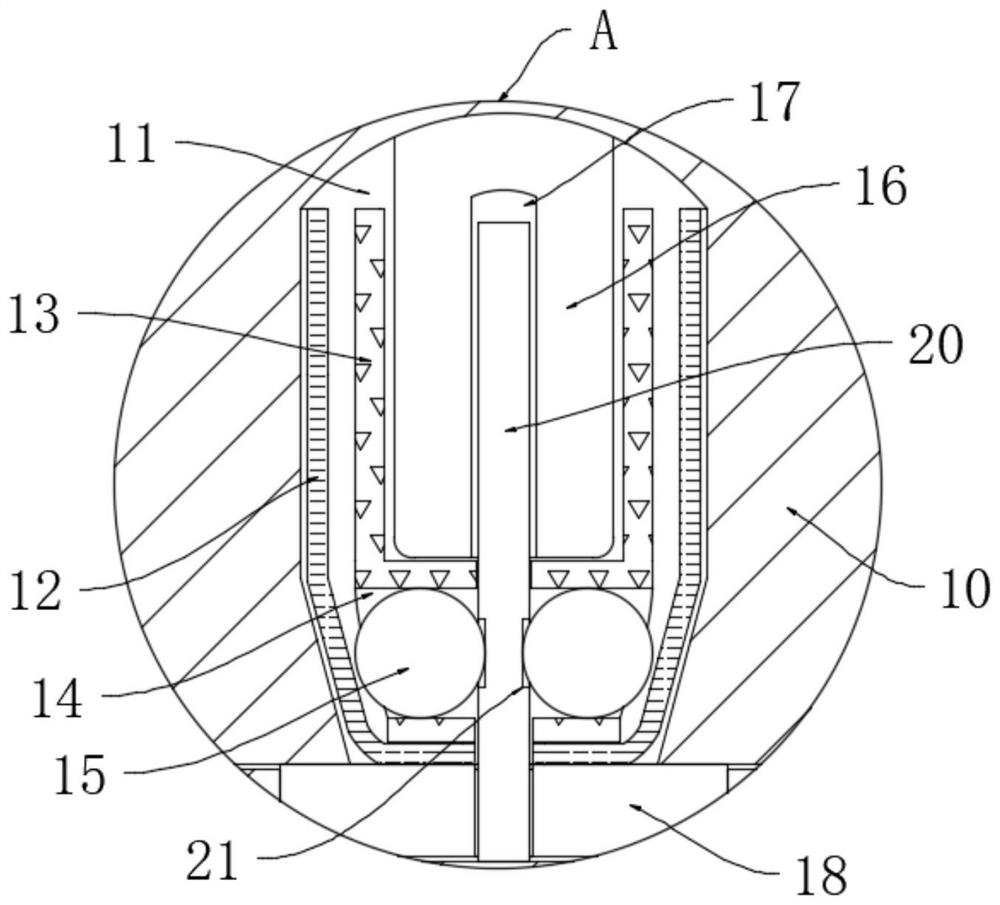

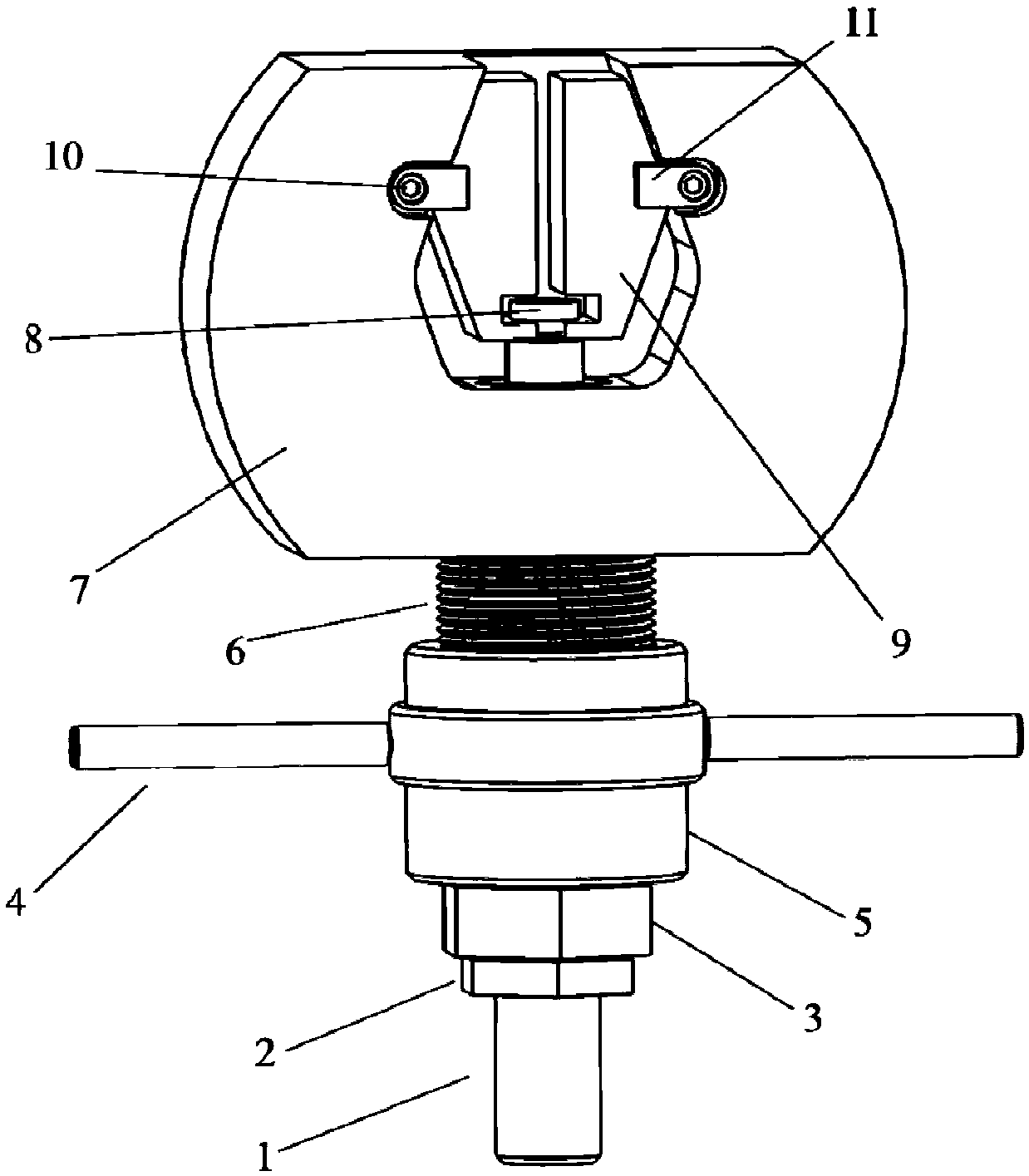

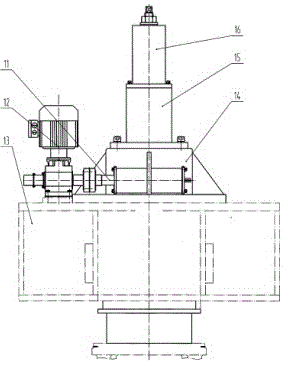

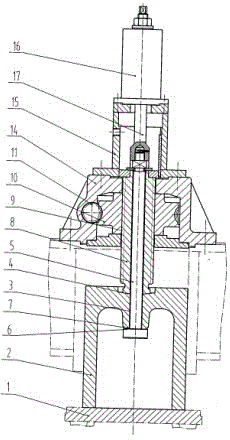

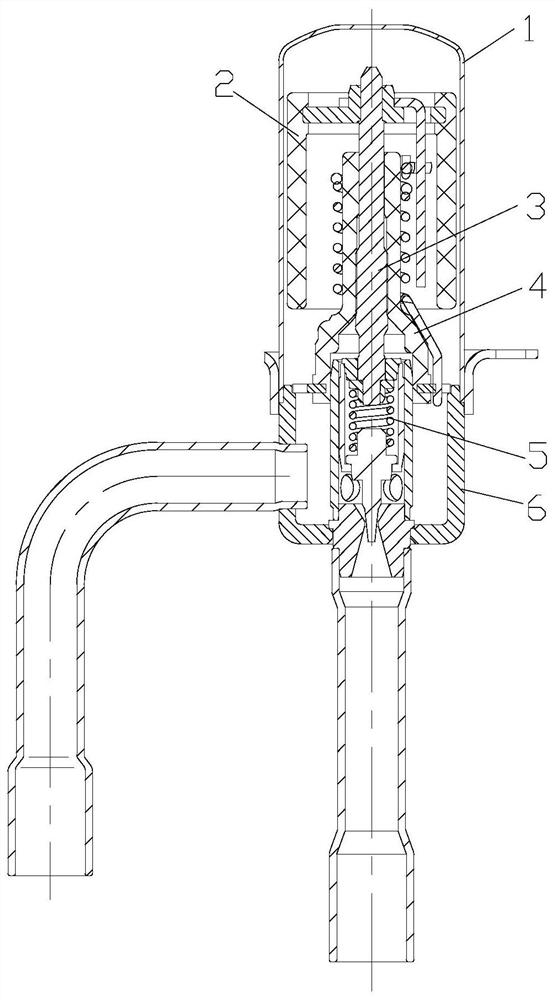

Rotating hub type under-pressure balancing device of straightener

The invention discloses a rotating hub type under-pressure balancing device of a straightener and solves the problem about poor balancing reliability of existing mechanical balancing device of equipment. The rotating hub type under-pressure balancing device of the straightener is characterized in that a worm gear (10) arranged on a worm gear and worm speed reducer (14) is provided with a through hole (9) with a screw fastener, a hollow screw (8) is screwed in the through hole (9), a tubular hydraulic cylinder seat (15) and a hollow hydraulic cylinder (16) are fixedly arranged on the worm gear and worm speed reducer (14), a hemispherical groove (4) is reserved on the top surface of a rotating hub (2), a cavity boss (7) is arranged in an inner cavity of the rotating hub (2), a balance through hole (3) is reserved between the hemispherical groove (4) and the cavity boss (7), an inverted T-shaped balance shaft (5) sequentially penetrates through the balance through hole (3) and a central hole of the hollow screw (8) from bottom to top to be connected with an output shaft (17) of the hollow hydraulic cylinder (16), and the bottom end of the hollow screw (8) is abutted against the hemispherical groove (4). The rotating hub type under-pressure balancing device is adjustable in balance force and easy to mount and maintain.

Owner:太原通泽智能工程股份有限公司

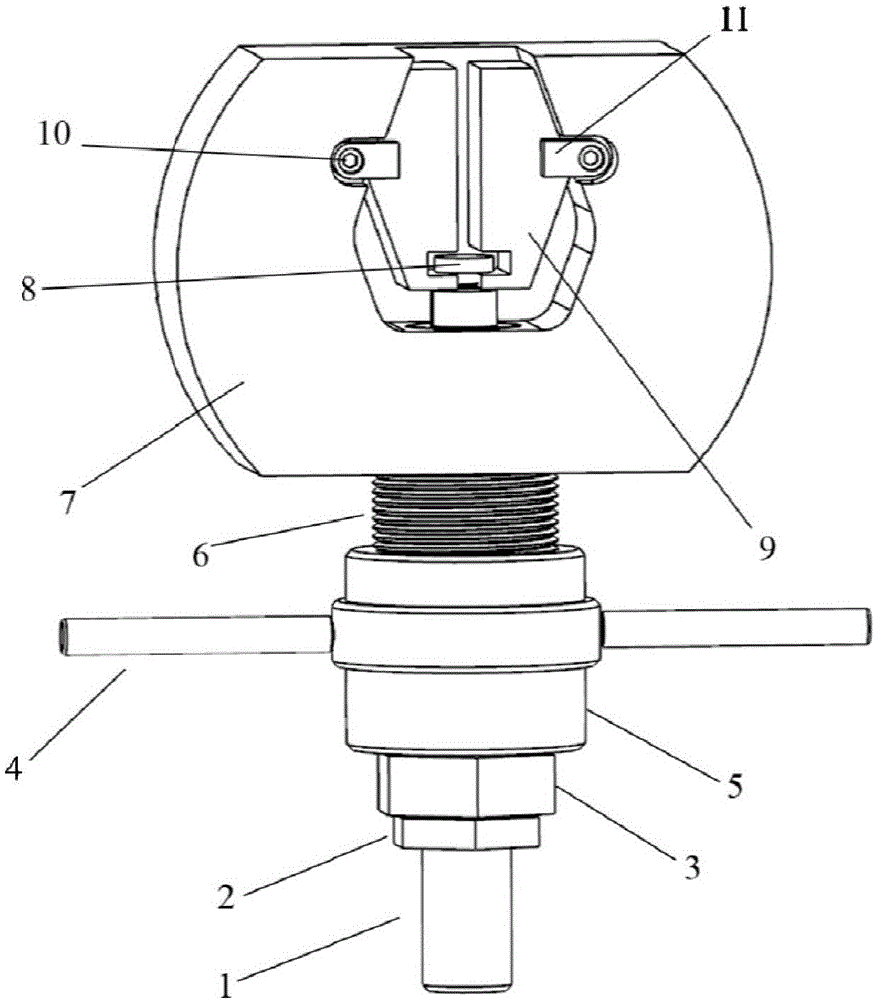

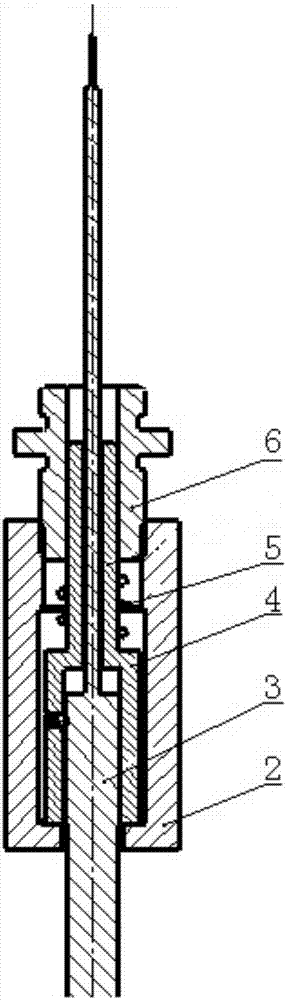

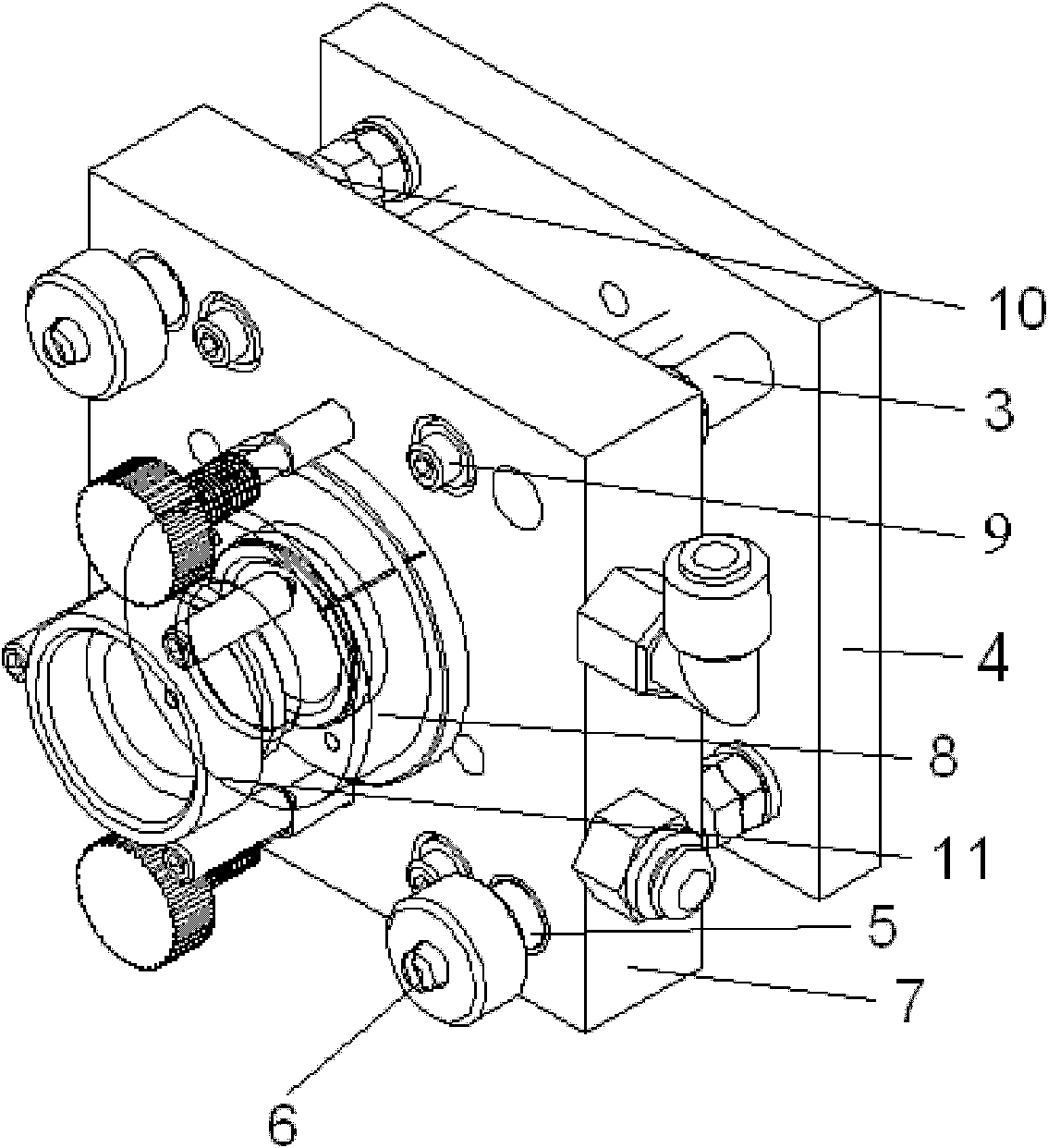

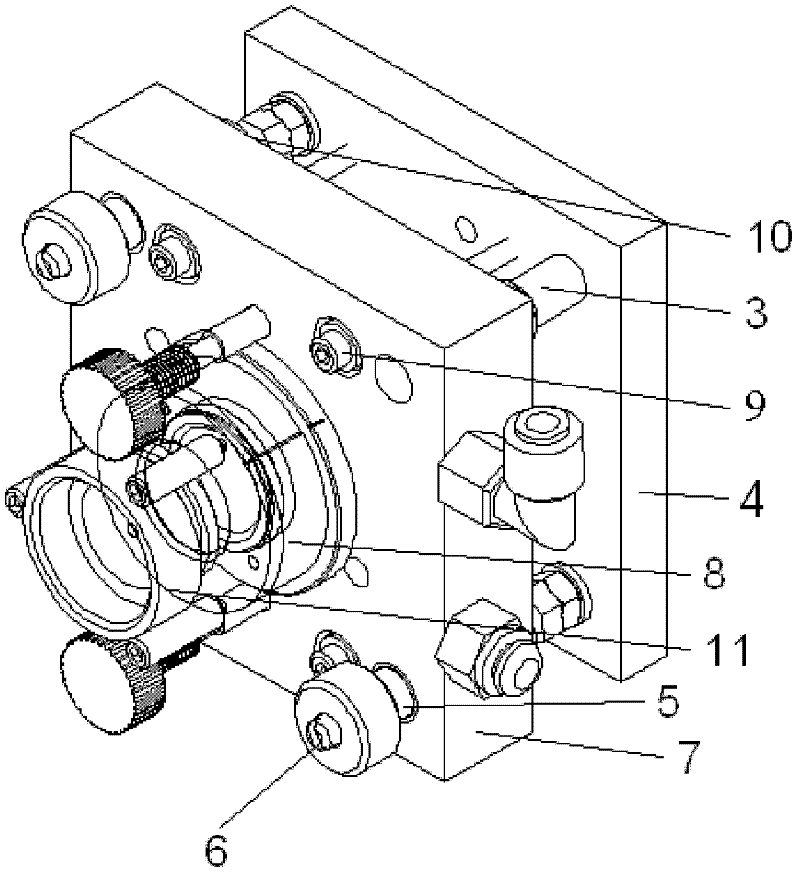

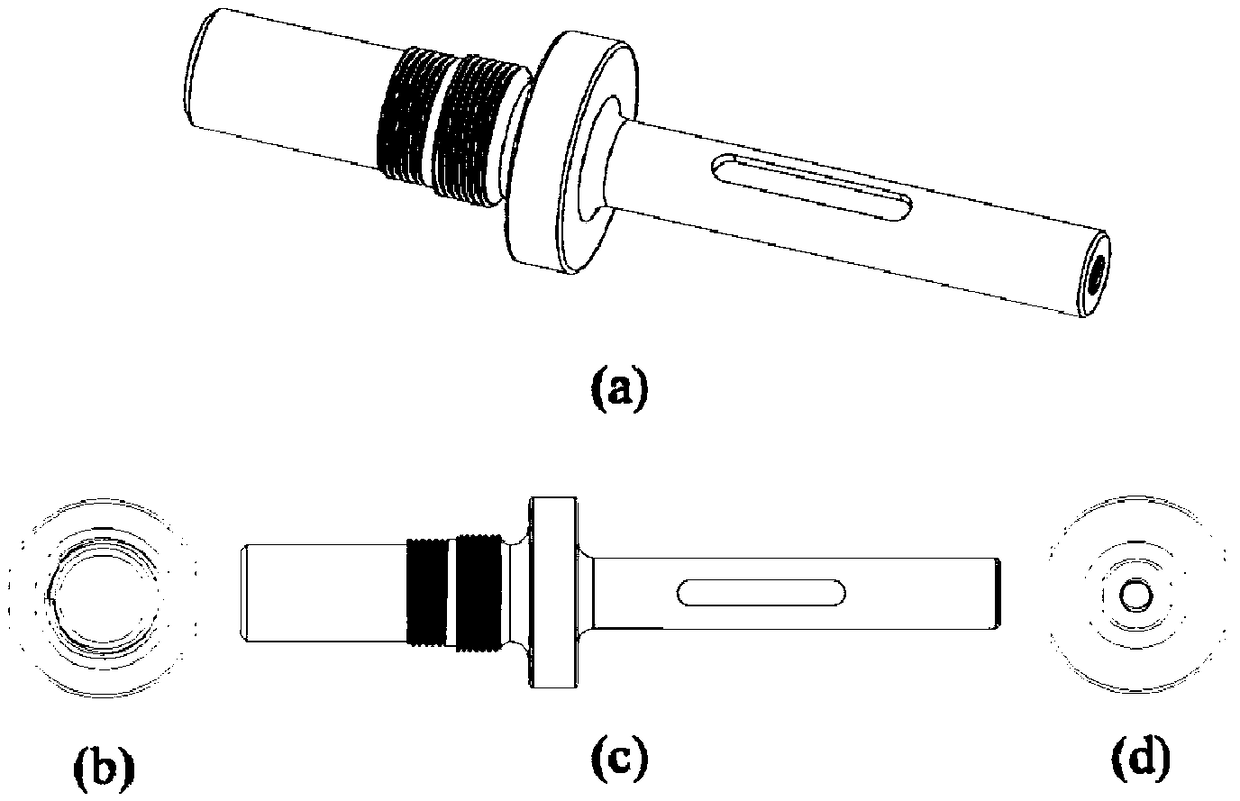

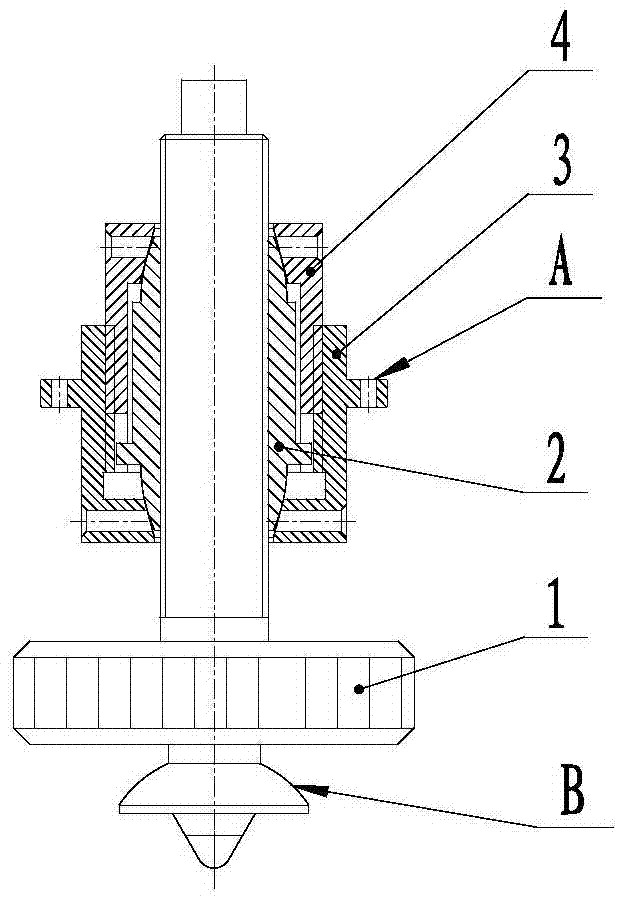

Adjustment device and method for measuring nanometer non-contact optical fiber sensor

ActiveCN107357317AAccurate displacementEliminate thread clearanceUsing optical meansControl using feedbackImage resolutionEngineering

The invention discloses an adjustment device and method for measuring a nanometer non-contact optical fiber sensor. The adjustment device comprises an adjustment nut. An optical fiber sensor is arranged in the lower part of the adjustment nut in a penetrating manner, and a fixing rod is arranged in the upper part in a penetrating manner. The optical fiber sensor is installed in the fixing rod through a hole below the fixing rod. The upper part of the fixing rod is sleeved with a fixing screw rod, and the outer side of the lower part of the fixing screw rod is in threaded connection with the inner side of the upper part of the adjustment nut. According to the invention, accurate adjustment during the pre-installation of the measuring range and in the experimental measurement can be ensured before the measurement of the nanometer optical fiber sensor in a small experimental space, so that the nanometer optical fiber displacement sensor can reach the measuring range of the optimum resolution.

Owner:SHAANXI UNIV OF SCI & TECH

Depressing and balancing device for steel section straightener

The invention discloses a depressing and balancing device for a steel section straightener, which is mainly designed to solve the problem of poor steel section straightening effect. The depressing and balancing device comprises two sets of depressing devices with depressing screws, and a driving device used for driving the depressing screws to ascend and descend, and further comprises adjustment devices used for adjusting the depressing screws, wherein each adjustment device comprises a lifting mechanism parallel to the corresponding depressing screw; and each lifting mechanism comprises a fixed part and a movable part moving along the fixed part, the fixed part of each lifting mechanism is fixed on a rack box body, and the movable part of each lifting mechanism is connected with the lower end of the corresponding depressing screw. The vertical position adjustment of an upper rolling system is realized through a gear motor, thread gaps between the depressing screws and nuts are eliminated through hydraulic cylinders, the maintenance is convenient, and the problems of big bounce and poor straightening effect of the steel section straightener during steel section straightening are solved.

Owner:HUATIAN ENG & TECH CORP MCC

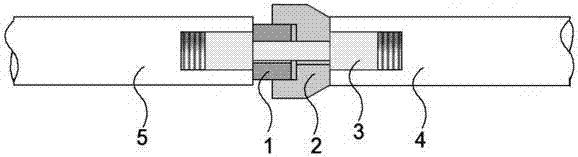

Protective device of reflection type Hopkinson pull rod test sample, and experimental method

ActiveCN107478501ASimple structureEliminate thread clearanceStrength propertiesGroove widthExperimental methods

The invention belongs to the field of material performance testing, and relates to a protective device of a reflection type Hopkinson pull rod test sample, and an experimental method. The protective device comprises an inner sleeve and an outer sleeve; a groove is formed in the single side of each of the inner sleeve and the outer sleeve; the cross section of the bottom of the groove is semi-circular, and the diameter and the groove width are equal; the external thread is formed on the outer surface of the inner sleeve and is connected with the internal thread at the position of a screw hole of the outer sleeve; and the diameter of the fitting end face of the outer sleeve and a working rod is equal to that of the working rod. According to the protective device of the reflection type Hopkinson pull rod test sample, and the experimental method, the experimental error generated by threaded gap in the stretching direction of the reflection type Hopkinson pull rod equipment is eliminated, the accuracy of the experimental result is improved, and operation is convenient and rapid.

Owner:GRIMAT ENG INST CO LTD

Screw element, screw connection and method for producing screw element

InactiveCN102356245AEliminate thread clearanceConstant braking torqueNutsBoltsBrake torqueEngineering

Owner:哈特马特.弗莱格

Mirror regulation device for fast axial flow gas laser

InactiveCN102157885AFit closelyAvoid the influence of relative positionLaser constructional detailsResonant cavityDifferential screw

The invention discloses a mirror regulation device for a fast axial flow gas laser, which comprises a fixed plate, a mirror regulation plate and a mirror room, wherein the fixed plate is fixed on an end plate of a resonant cavity of the laser; the mirror regulation plate is arranged on the fixed plate; the mirror room is arranged on the mirror regulation plate; a lens is arranged in the mirror room; a gas curtain pressure cover is arranged on the mirror room; the mirror regulation plate is connected with a screw hole of the fixed plate by long screws; differential screws and matched screw rods are arranged on the mirror regulation plate; the differential screw is in threaded connection with the mirror regulation plate; the front end of the matched screw rod is in threaded connection with the interior of the differential screw, and the tail end of the matched screw rod is pressed against a supporting pin fixed on the fixed plate; and the mirror regulation plate is pressed against one side, provided with the supporting pins, of the fixed plate. The mirror regulation device has the characteristics of stable performance, mounting simplicity and convenience of regulation, and ensures the stability of laser output.

Owner:HUAZHONG UNIV OF SCI & TECH

Sample fatigue tension and compression loading test device and installation method

PendingCN114323924AImprove connection stiffnessGuaranteed resonanceMaterial strength using repeated/pulsating forcesMetallic materialsEngineering

The invention relates to the technical field of metal material fatigue performance test device structures, in particular to a sample fatigue tension and compression loading test device and an installation method. Comprising a sample connecting flange table and an annular structure which sleeves the outer side of the circumference of a sample and is in external thread connection with the outer side of the circumference of the sample, one end of the testing machine connecting flange table is connected with the testing machine, and the other end abuts against the axial end of the sample and is used for transmitting load to the sample; the pressing structure is used for driving the sample connecting flange table to press towards one side of the testing machine connecting flange table, so that the axial end part of the sample is tightly propped against the testing machine connecting flange table, and a thread gap between the sample and the sample connecting flange table is eliminated. The test device is simple in structure and convenient to operate, can well eliminate thread gaps between the sample and all parts, increases the connection rigidity between the sample and all the parts, ensures the resonance of a resonance system of the fatigue testing machine, and has great popularization value.

Owner:DONGFENG MOTOR GRP

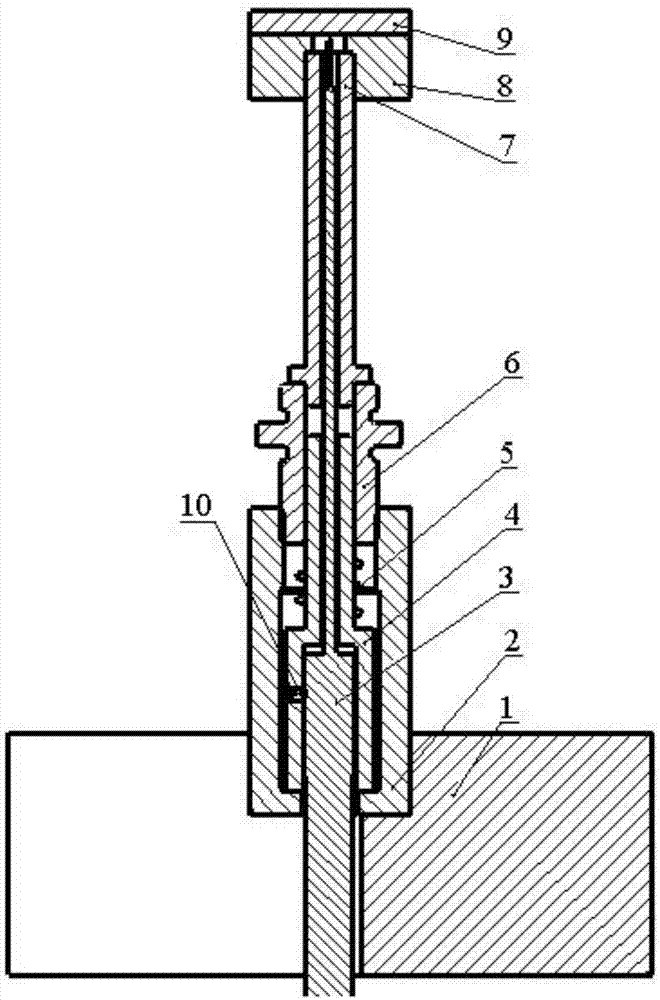

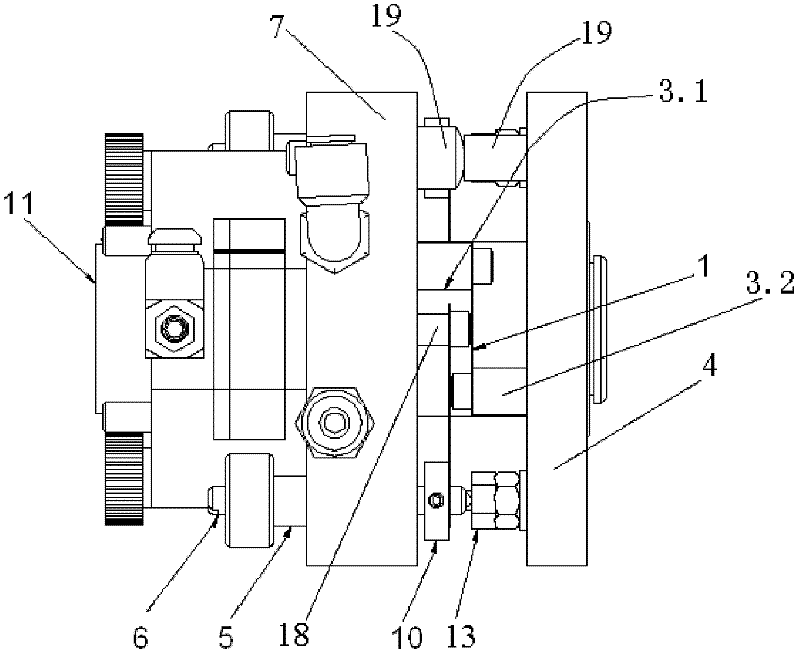

Fine blanking machine upper die with adjusting device

InactiveCN109013875AEffectively exclude thread gapsEliminate thread clearanceShaping toolsPressesEngineeringDrive motor

The invention relates to a fine blanking machine upper die with an adjusting device. The fine blanking machine upper die comprises an upper die body. The upper die body comprises an upper die plate and an upper die device. The upper die adjusting device is arranged in a manner of being connected with the upper die plate and comprises an upper die lifting device and an upper die balance locking device. The upper die lifting device comprises a nut sleeve in threaded connection with the outer wall of the upper die plate. A gear disc is fixedly connected with the nut sleeve. A small gear is in engaged connection with the gear disc. The small gear is mounted at the output end of a downwards-arranged lifting drive motor connected with the top of a fine blanking machine body. The upper die balance locking device comprises a balance locking oil cylinder mounted at the top of the fine blanking machine body, the balance locking oil cylinder is arranged downwards, and a piston rod of the balancelocking oil cylinder is fixedly connected with the center portion of the upper die plate. The fine blanking machine upper die is simple and practical in structure improvement, adjusting operation is convenient, the machining precision is guaranteed, and the good actual use and popularization value is achieved.

Owner:黄石华力锻压机床有限公司

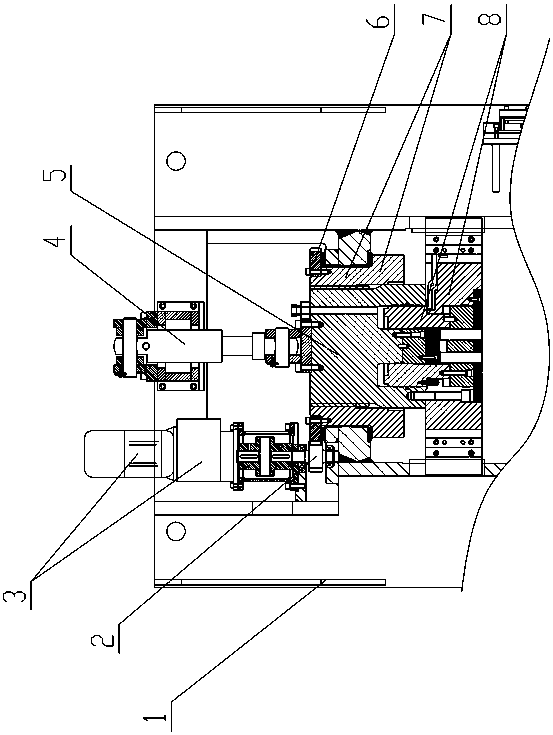

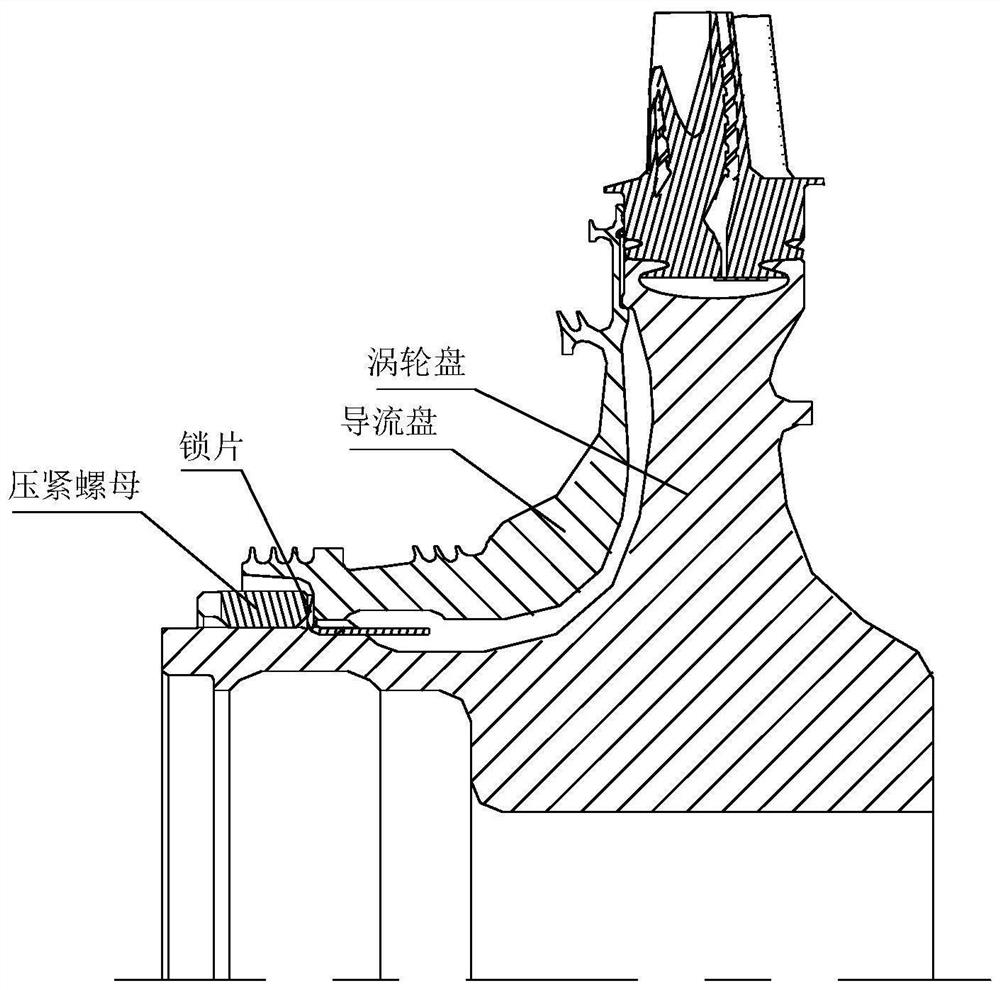

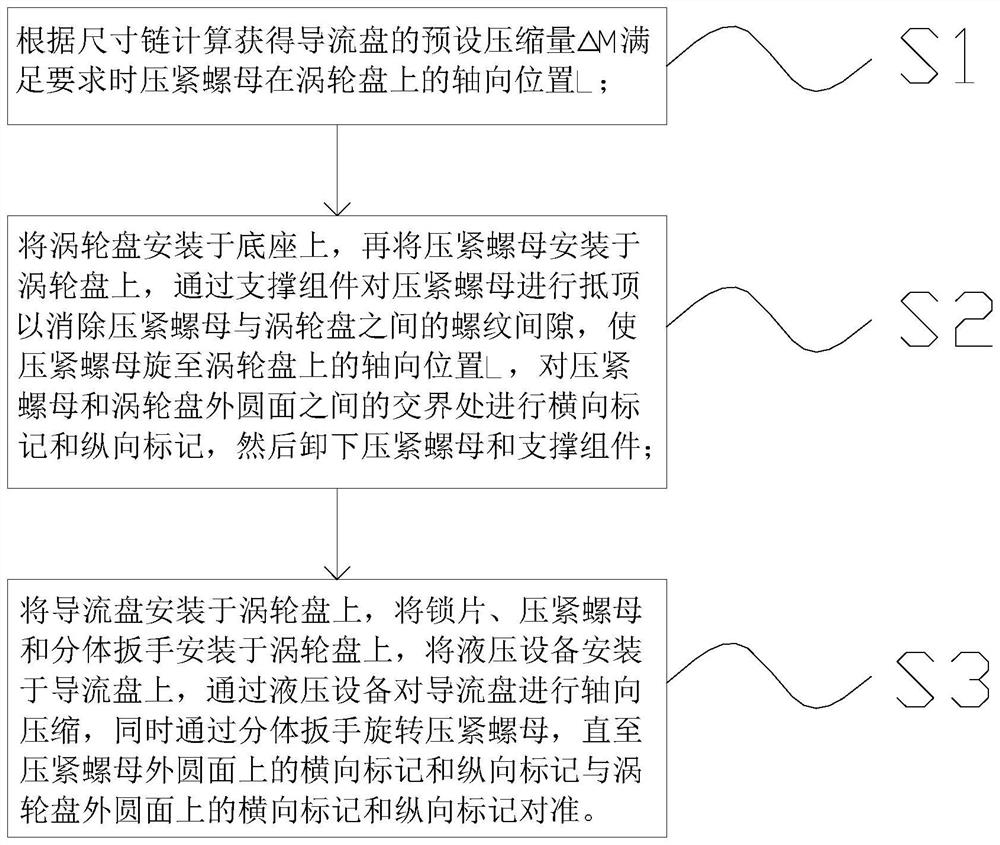

Flow guide disc installation method and installation device

PendingCN114837751AImprove installation qualityGuaranteed installation qualityBlade accessoriesHydro energy generationEngineeringHydraulic equipment

The invention discloses a flow guide disc installation method. The method comprises the steps that firstly, the axial distance L between the upper end face of a compression nut and the tooth top face of the upper end of a turbine disc is obtained through size chain calculation when the compression amount of a flow guide disc reaches the preset compression amount M; then, under the condition that the flow guide disc is not installed, the compression nut is made to move by the axial distance L relative to the turbine disc, and transverse marking and longitudinal marking are conducted on the junction between the compression nut and the outer circle face of the turbine disc; the supporting assembly abuts against the pressing nut so that a thread gap between the pressing nut and the turbine disc can be eliminated. Finally, the flow guide disc is axially compressed through hydraulic equipment, meanwhile, the compression nut is rotated through the split wrench, compared with the prior art, a high-torque wrench does not need to be used for screwing the compression nut, and damage to compression nut threads, turbine disc threads and turbine disc end teeth caused by thread friction force is avoided; and the compression amount can be adjusted without repeatedly disassembling and assembling the flow guide disc, so that the mounting quality and efficiency are obviously improved.

Owner:CHINA HANGFA SOUTH IND CO LTD

Dip angle regulating device

InactiveCN100507626CAchieve the purpose of the inventionIndependent adjustment of usage characteristicsSurveying instrumentsMountingsEngineeringMechanical engineering

Owner:ASIA OPTICAL CO INC

A kind of protective device and experimental method for reflective Hopkinson tie rod sample

ActiveCN107478501BSimple structureEliminate thread clearanceStrength propertiesTest sampleScrew thread

The invention belongs to the field of material performance testing, and relates to a protective device of a reflection type Hopkinson pull rod test sample, and an experimental method. The protective device comprises an inner sleeve and an outer sleeve; a groove is formed in the single side of each of the inner sleeve and the outer sleeve; the cross section of the bottom of the groove is semi-circular, and the diameter and the groove width are equal; the external thread is formed on the outer surface of the inner sleeve and is connected with the internal thread at the position of a screw hole of the outer sleeve; and the diameter of the fitting end face of the outer sleeve and a working rod is equal to that of the working rod. According to the protective device of the reflection type Hopkinson pull rod test sample, and the experimental method, the experimental error generated by threaded gap in the stretching direction of the reflection type Hopkinson pull rod equipment is eliminated, the accuracy of the experimental result is improved, and operation is convenient and rapid.

Owner:GRIMAT ENG INST CO LTD

Method and apparatus for cracking wall loose of conic cracker

InactiveCN1978062AEliminate thread clearanceGood anti-loose effectGrain treatmentsEngineeringCrusher

The present invention discloses a method for preventing crushing wall of cone crusher from loosening. It is characterized by that said method includes the following steps; screwing a holddown nut with small pitch and small diameter into said cone body interior, then screwing another holddown nut with large pitch and large diameter into said cone body interior; after the crushing wall is tightly pressed, using screw bolt to make the above-mentioned holddown nuts be connected together; then screwing puller bolt into the holddown nut with large pitch and large diameter until the holddown nut with small pitch and small diameter is tightly pressed.

Owner:SHANGHAI JIANSHE LUQIAO MASCH CO LTD

A splicing type ceramic insulator with reinforcing rib structure

The invention relates to the technical field of power transmission lines, in particular to a splicing type ceramic insulator with a reinforcing rib structure, comprising a base, a mounting foot is fixedly installed on the base, a screw rod is fixedly installed on the base, and a screw rod is threadedly connected to the base The connection unit is fixedly installed with a spring, the connection unit is hinged with a reinforcing rib, and the reinforcing rib is hinged on the slider, the slider is slidably connected in the chute, and the connection unit is connected The insulator monomer is fixedly connected, and the insulator monomer is provided with a mandrel; the insulator is mainly composed of insulator monomers spliced one by one, and its length can be controlled within any range, and the splicing is very convenient, using memory alloy material. The pressure rod is assembled at a high temperature, and can be firmly connected after returning to normal temperature. It is impossible to reach the deformation temperature of the memory pressure rod under the normal use state of the insulator, which ensures the safety of the insulator.

Owner:孙水平

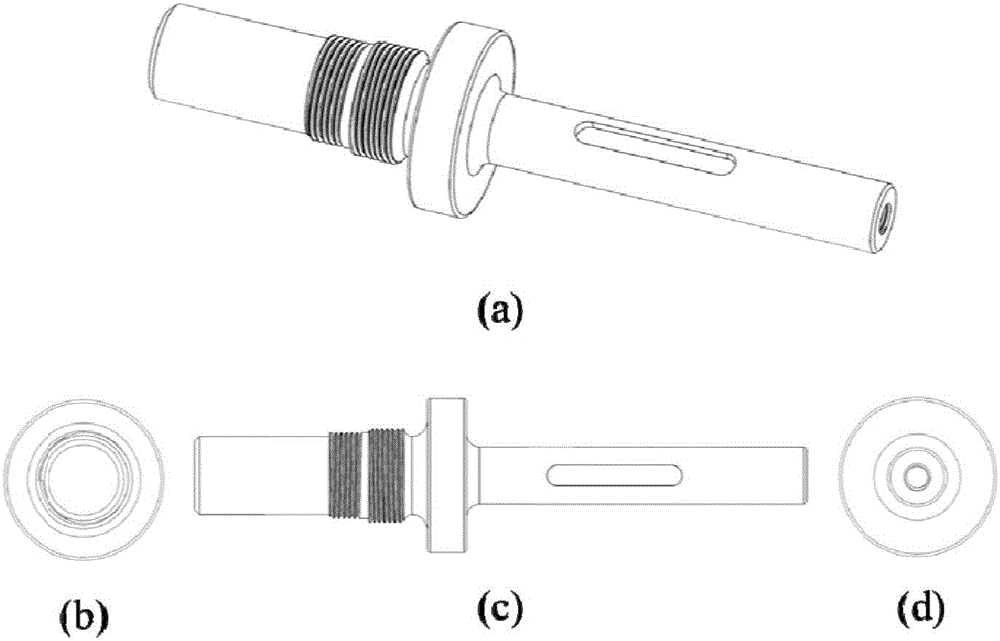

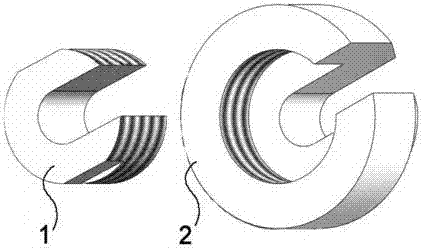

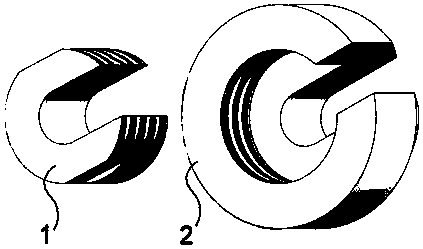

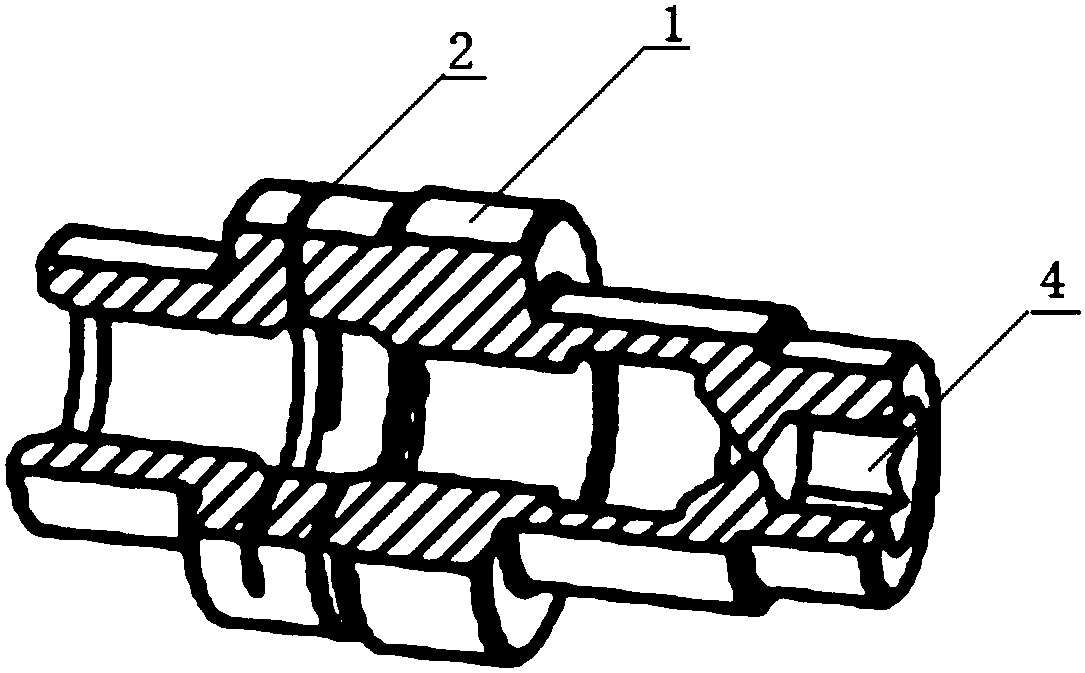

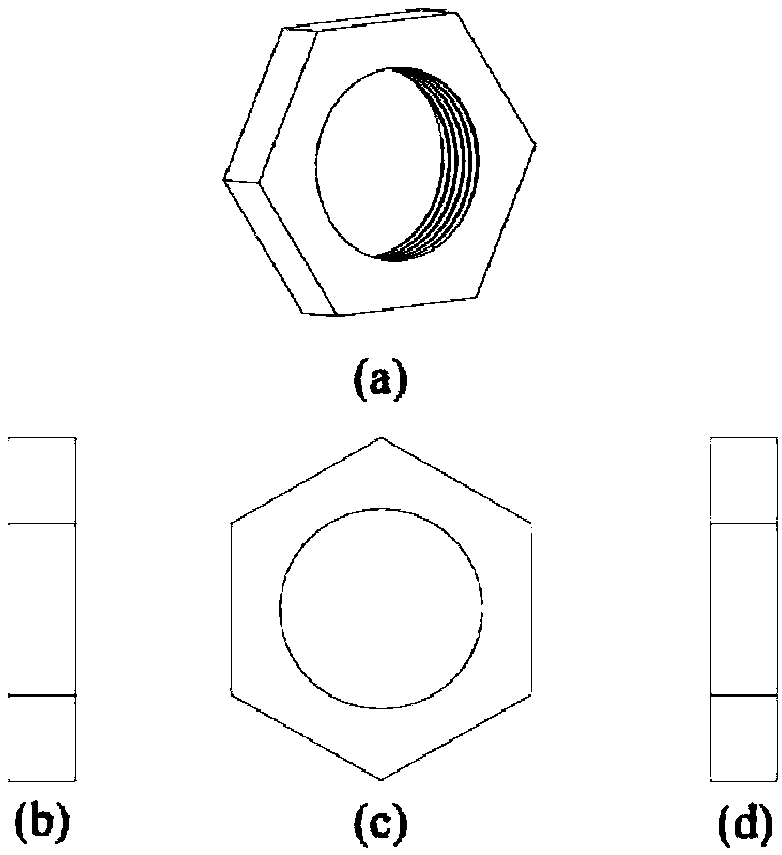

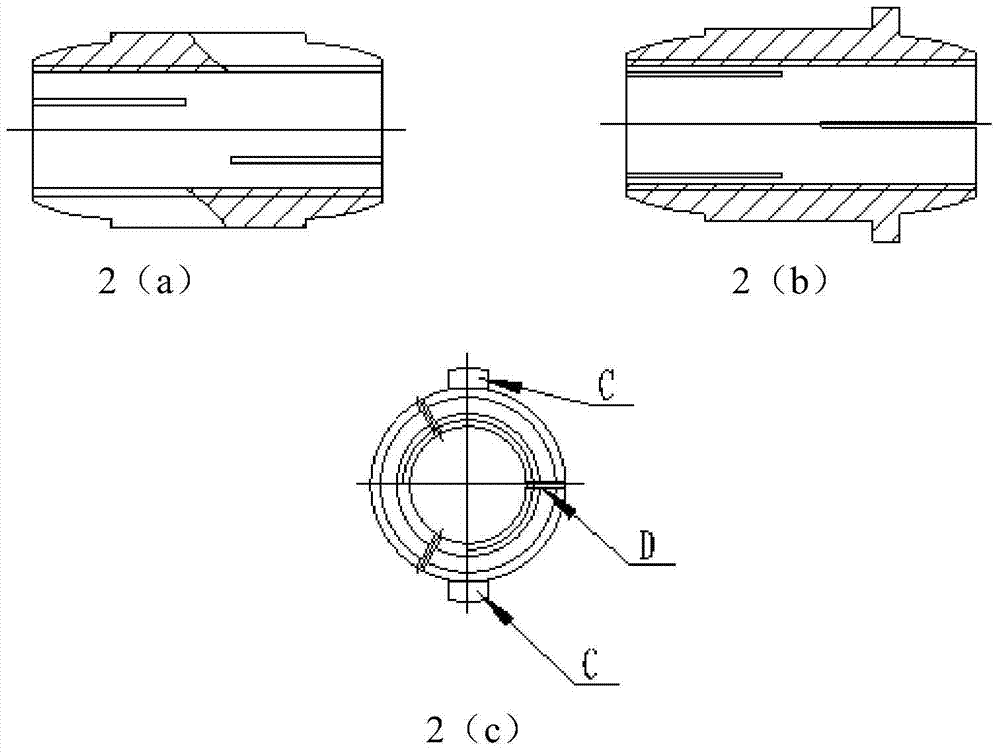

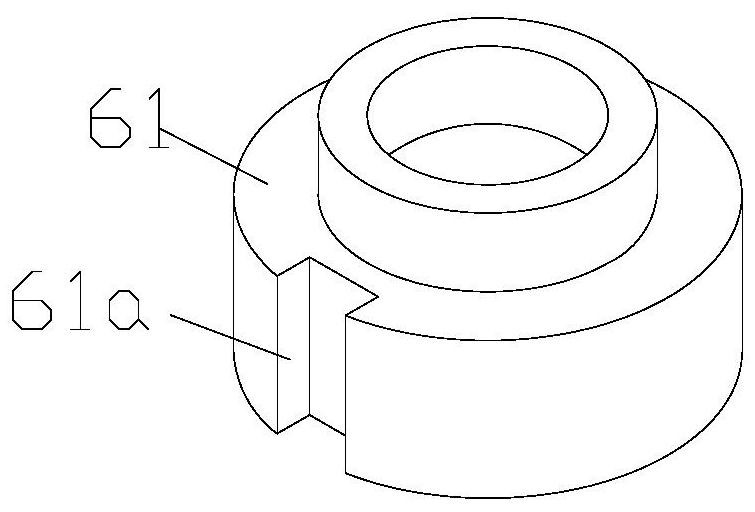

A rotary screw sleeve for a fine-tuning boring unit

ActiveCN105945314BEliminate thread clearanceAchieve backlash-free relative movementBoring headsEngineeringFine-tuning

The invention relates to a rotation threaded sleeve of a fine adjustment boring cutter unit. An annular boss is arranged on the outer circumferential face of the rotation threaded sleeve. Narrow grooves are formed in the outer cylindrical face of the annular boss in the radial direction, and the depth of the narrow grooves is larger than the radius of the part, at the position, of the outer cylindrical face. A clearance groove is formed in the rotation threaded sleeve and partitions an inner threaded hole in the rotation threaded sleeve into two sections. The narrow grooves are located in the clearance groove, the two narrow grooves are staggered in the axial direction, and the difference of the opening directions of the two narrow grooves is 180 degrees. The clearance groove is formed to divide the inner threaded hole in the rotation threaded sleeve into two sections, and meanwhile the two reverse narrow grooves staggered in the axial direction are cut out at the position of the clearance groove of the rotation threaded sleeve. By means of the fine adjustment boring cutter unit, under the action of a spring, fine deformation of the narrow grooves formed in the two positions happens so that two threaded sections originally continuous deform in the axial direction, a thread gap of a cutter rod thread and the rotation threaded sleeve is eliminated, and a cutter rod and the rotation threaded sleeve can relatively move without gaps.

Owner:成都新成量工具有限公司

Mirror regulation device for fast axial flow gas laser

InactiveCN102157885BFit closelyAvoid the influence of relative positionLaser constructional detailsResonant cavityDifferential screw

The invention discloses a mirror regulation device for a fast axial flow gas laser, which comprises a fixed plate, a mirror regulation plate and a mirror room, wherein the fixed plate is fixed on an end plate of a resonant cavity of the laser; the mirror regulation plate is arranged on the fixed plate; the mirror room is arranged on the mirror regulation plate; a lens is arranged in the mirror room; a gas curtain pressure cover is arranged on the mirror room; the mirror regulation plate is connected with a screw hole of the fixed plate by long screws; differential screws and matched screw rods are arranged on the mirror regulation plate; the differential screw is in threaded connection with the mirror regulation plate; the front end of the matched screw rod is in threaded connection with the interior of the differential screw, and the tail end of the matched screw rod is pressed against a supporting pin fixed on the fixed plate; and the mirror regulation plate is pressed against one side, provided with the supporting pins, of the fixed plate. The mirror regulation device has the characteristics of stable performance, mounting simplicity and convenience of regulation, and ensures the stability of laser output.

Owner:HUAZHONG UNIV OF SCI & TECH

A high-temperature tensile fatigue test fixture and method for flat specimens

ActiveCN106840867BStable clampingAchieving Stretch FatigueMaterial strength using tensile/compressive forcesTensile fatigueTest fixture

The invention discloses a high temperature tensile fatigue test fixture for a panel test piece and a method. The clamping for the panel test piece in a high temperature test is realized, so that the tensile fatigue test for the panel test piece can be performed under a high temperature condition. A hydraulic chuck of a fatigue machine is used for clamping an optical rod end of a central shaft and is connected with a connecting rod through a sleeve; a fixing nut is arranged on the central shaft; the fixing nut is used for limiting the downward movement of the sleeve; the connecting rod is fixed with the sleeve through a screw; the connecting rod is in threaded connection with a wedge-shaped chuck body; the central shaft passes through a through hole in the middle of the connecting rod; a shaft end is connected with a guiding platform; the guiding platform is located in a groove between two wedge-shaped clamp blocks and is used for guiding the wedge-shaped clamp blocks to move up and down; the test piece is clamped by the wedge-shaped clamp blocks in the wedge-shaped chuck body; the bottoms of the wedge-shaped clamp blocks are propped by the top end of the guiding platform; the two sides are in contact with the wedge-shaped plane in the wedge-shaped chuck body; the upwards movement of the wedge-shaped clamp blocks is limited. The high temperature tensile fatigue test fixture can meet the requirement for stably clamping the panel test pieces in various sizes and can realize the single-shaft tensile fatigue under the high temperature condition.

Owner:BEIHANG UNIV

Crus adjustment system for rehabilitation robot

ActiveCN103068447BHigh transmission precisionReduce mistakesGymnastic exercisingChiropractic devicesTorque sensorSacroiliac joint

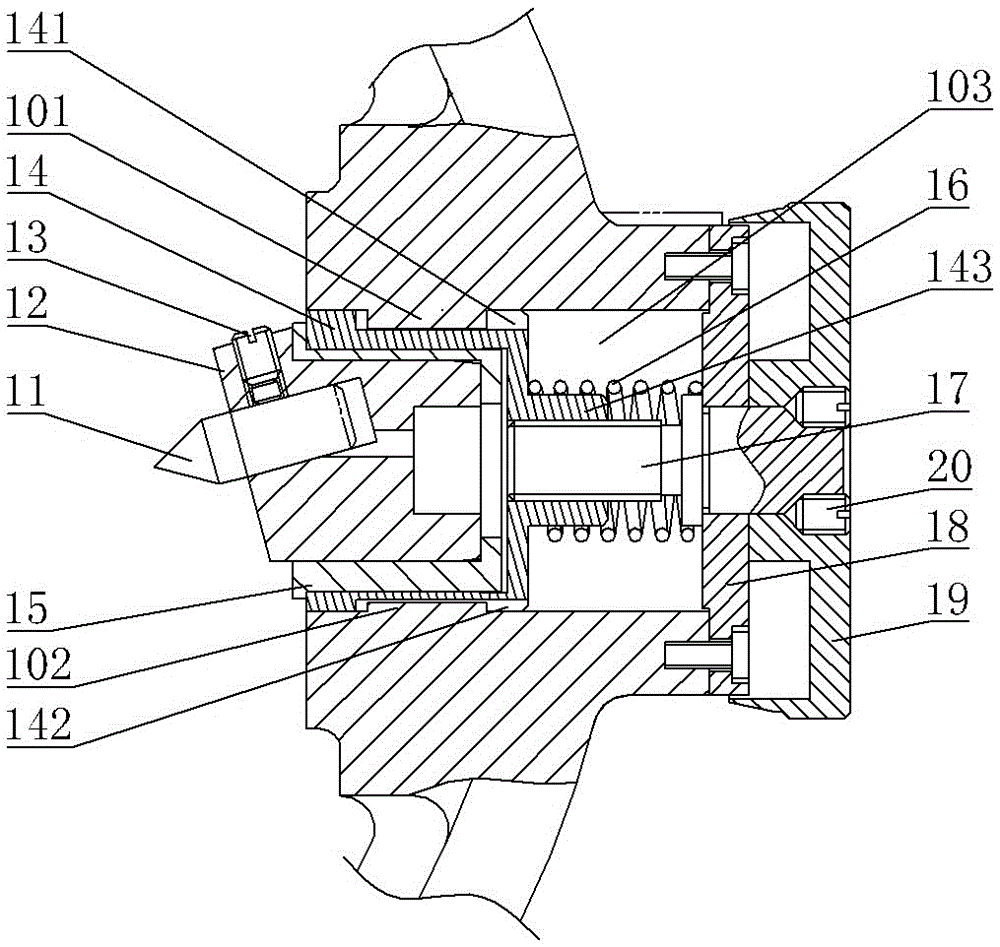

A crus adjustment system for a rehabilitation robot includes a crus extension / contraction unit and a knee joint rotation unit. A motor (15) drives a screw rod (2) to rotate, and accordingly drives a screw rod nut and a connecting frame (4) to cause a dovetail groove guide rail (1) fixed to the connecting frame (4) to move, thus enabling extension / contraction of the crus during rehabilitation training. A pulley (10) drives a torque sensor (25) fixed on a torque sensor seat (24), and accordingly drives the whole knee joint, thus enabling the knee joint to rotate. The system has two degrees of freedom, and has the advantages of high positional precision, good intuitive sense for movement, high overall rigidity, simple structure and easy manufacture.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

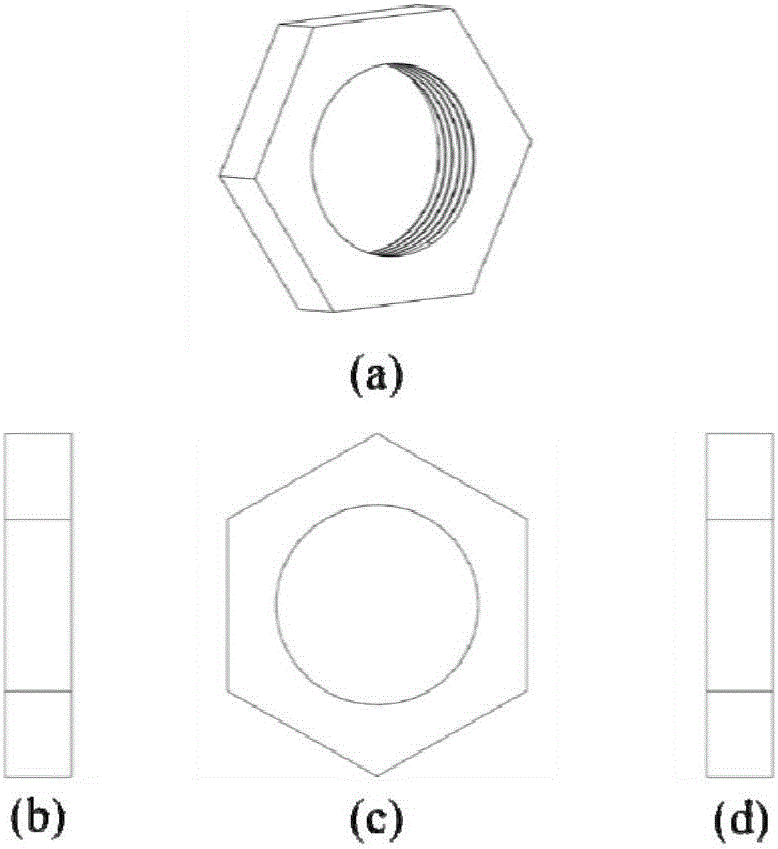

A kind of backlash-free screw adjusting mechanism

The invention discloses a gapless thread adjusting mechanism which comprises an adjusting screw, a guide nut, a pretightening nut and a pretightening screw cap. The adjusting screw is cylindrical, an external thread is processed on the outer surface of the adjusting screw, the guide nut is placed outside the adjusting screw in a sleeved manner, an internal thread matched with the external thread of the adjusting screw is processed on the inner surface of the guide nut, each of two ends of the guide nut is a conical face, a deformation groove is formed in each of two end faces of the guide nut, the pretightening nut is placed outside the guide nut in a sleeved manner, an internal thread is processed on the inner surface of one end of the pretightening nut, the other end of the pretightening nut is a conical face which is matched with one conical face of the guide nut, the pretightening screw cap is placed outside the guide nut in a sleeved manner, an internal thread is processed on the inner surface of one end of the pretightening screw cap, the other end of the pretightening screw cap is a conical face which is matched with the other conical face of the guide nut, and the internal thread of the pretightening nut and the external thread of the pretightening screw cap are in matched connection to enable the guide nut and the adjusting screw to be positioned in an inside cavity formed by the pretightening nut and the pretightening screw cap.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

Rotating hub type under-pressure balancing device of straightener

The invention discloses a rotating hub type under-pressure balancing device of a straightener and solves the problem about poor balancing reliability of existing mechanical balancing device of equipment. The rotating hub type under-pressure balancing device of the straightener is characterized in that a worm gear (10) arranged on a worm gear and worm speed reducer (14) is provided with a through hole (9) with a screw fastener, a hollow screw (8) is screwed in the through hole (9), a tubular hydraulic cylinder seat (15) and a hollow hydraulic cylinder (16) are fixedly arranged on the worm gear and worm speed reducer (14), a hemispherical groove (4) is reserved on the top surface of a rotating hub (2), a cavity boss (7) is arranged in an inner cavity of the rotating hub (2), a balance through hole (3) is reserved between the hemispherical groove (4) and the cavity boss (7), an inverted T-shaped balance shaft (5) sequentially penetrates through the balance through hole (3) and a central hole of the hollow screw (8) from bottom to top to be connected with an output shaft (17) of the hollow hydraulic cylinder (16), and the bottom end of the hollow screw (8) is abutted against the hemispherical groove (4). The rotating hub type under-pressure balancing device is adjustable in balance force and easy to mount and maintain.

Owner:太原通泽智能工程股份有限公司

Clamp for high-temperature low-cycle fatigue test

PendingCN114324032AImprove test accuracyImprove cooling effectMaterial strength using repeated/pulsating forcesMechanical engineeringPiston

The invention discloses a high-temperature low-cycle fatigue test fixture which comprises a chuck body, a piston capable of reciprocating in the chuck body, a connecting rod capable of extending into a high-temperature environment, an ejector rod slidably arranged in the connecting rod and a cooling device, the chuck body is in sealed communication with one end of the connecting rod, and the other end of the connecting rod is connected with a sample connecting piece; a sample piece can penetrate through the sample connecting piece to be in contact with the ejector rod, one end of the piston is communicated with an oil cavity of the chuck body, the other end of the piston is connected with the ejector rod, the periphery of the piston is in sealed connection with an inner cavity of the chuck body, the chuck body is provided with a channel used for supplying hydraulic oil into the oil cavity, and the cooling device can be arranged in the circumferential direction of the chuck body. By using the clamp for the high-temperature low-cycle fatigue test, provided by the invention, a thread gap between the clamp and a material piece can be effectively eliminated in a high-temperature environment and in a mounting process.

Owner:中机试验装备股份有限公司

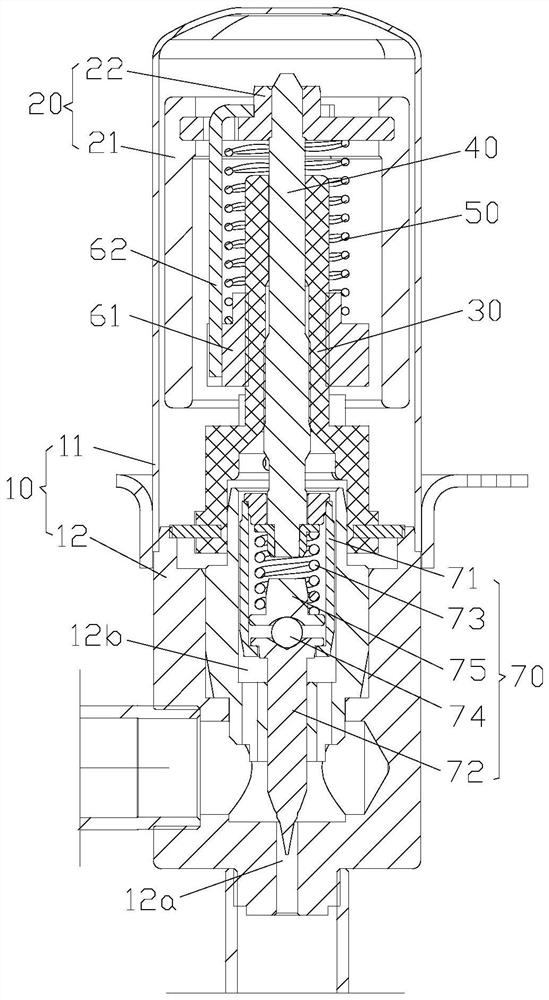

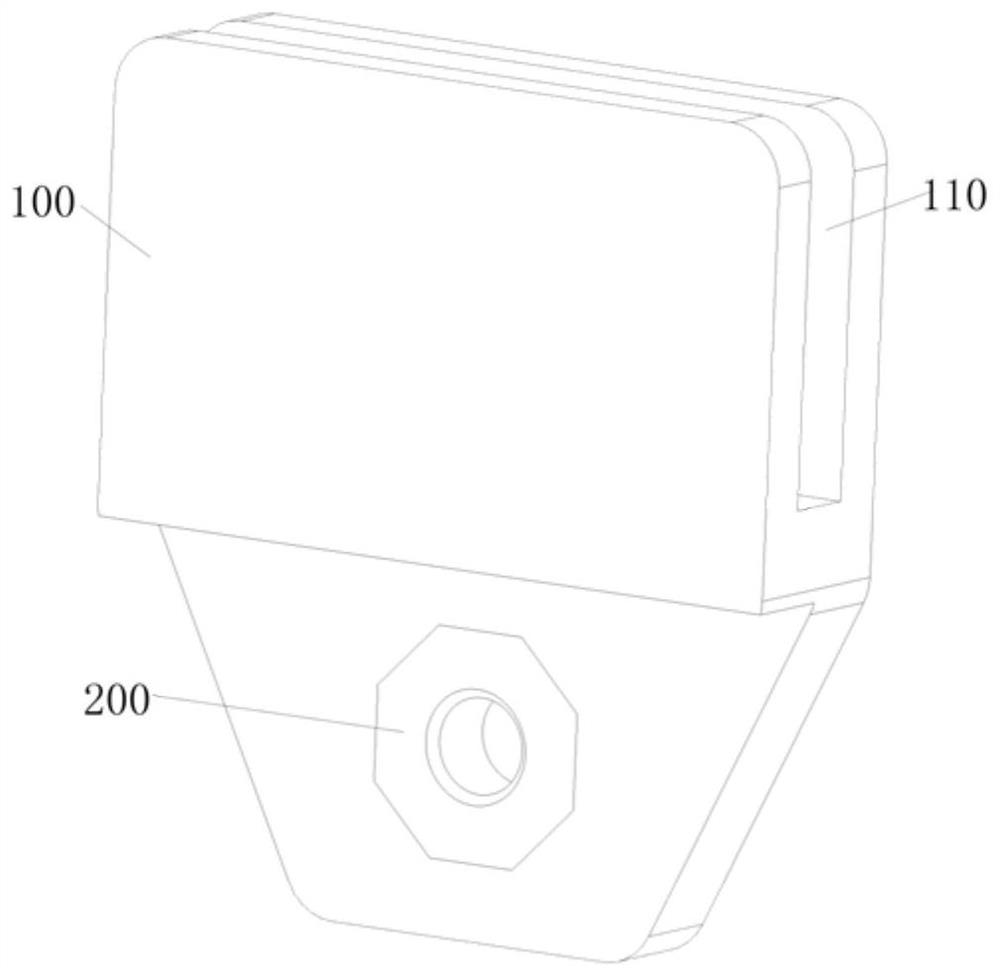

Electronic expansion valve

ActiveCN111059295BAvoid shakingEliminate thread clearanceEfficient regulation technologiesFluid circulation arrangementEngineeringMechanical engineering

Owner:SUZHOU HUAYUE METAL

Combined embedded nut for automobile door glass bracket

The invention discloses a combined embedded nut for an automobile door glass bracket. The combined embedded nut is characterized in that one end part of a first nut main body of a first nut extends outwards in the radial direction to form a first nut rim, a first connecting through hole is coaxially formed in the first nut main body, a plurality of preset torque pressure points are uniformly distributed on the first nut, the first nut rim is arranged to be of a non-cylindrical structure, one end part of a second nut main body of a second nut extends outwards in the radial direction to form a second nut rim, a second nut internal threaded hole is coaxially formed in the second nut main body, the automobile door glass bracket and automobile glass are locked on a glass lifter assembly throughthe two nut threaded through holes, the outer cylindrical surface of the second nut main body is a non-smooth surface column, the second nut rim is arranged to be of a non-cylindrical structure, andthe first nut and the second nut are integrated with the automobile door glass bracket through injection molding and are in close fit with each other. The nut is simple in forming structure, reliablein performance and low in cost, can be formed at a time, improves the material utilization rate, meets the light weight requirement and has the anti-loosening performance.

Owner:厦门同恒金属有限公司

Polishing head leveling device and method

The invention discloses a levelling device and a levelling method for a polishing head. The levelling device comprises a spline shaft, a spline hub, a bearing sleeve, a bearing end cap, a bearing pre-tightening ring, a bearing, an adjusting panel, a base plate and at least three levelling screw sets; the adjusting panel is arranged on the upper surface of the base plate; the bearing end cap is matched with the bearing pre-tightening ring for pre-tightening the outer ring of the bearing; the bearing is arranged between the spline hub and the bearing sleeve; the spline shaft is accommodated in the spline hub; and each levelling screw set is connected onto the adjusting panel. According to the levelling device, levelling operation is transferred to the polishing head through the spline shaft, and the area of the polishing head is large, so that the polishing head is applicable to polishing of wafers with large sizes. Loosening-proof flanges are used for eliminating threaded clearances between levelling nuts and the adjusting panel; the levelling precision is improved; and the phenomenon that a pre-levelled position is changed by friction force during a process of rotating fastening bolts is prevented.

Owner:BEIJING SEMICORE PRECISION MICROELECTRONICS EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com