Hydraulic locking device of pressure machine

A locking device and press technology, applied in the field of press locking, can solve the problems of affecting precision, low precision of stamping workpiece quality, reducing screw 2' and press die service life, etc., to improve precision and eliminate thread clearance , The effect of high precision of screw movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

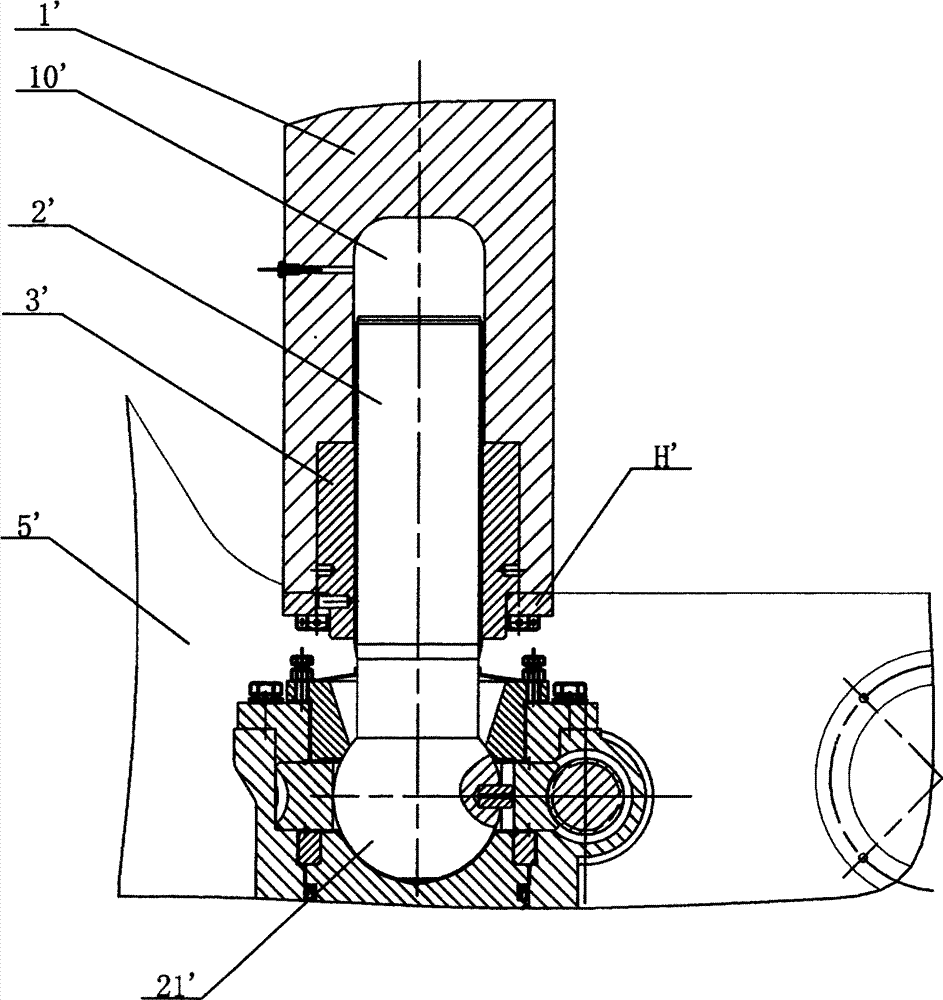

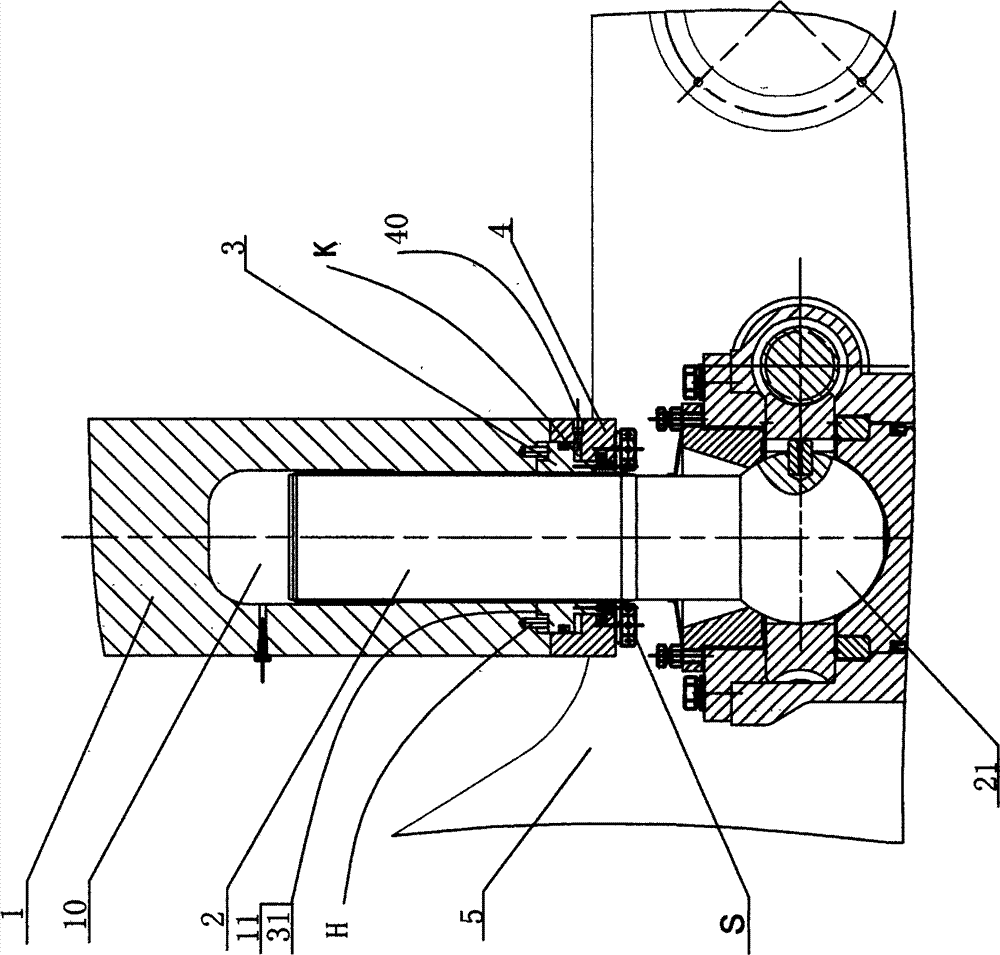

[0014] Please refer to figure 2 As shown, a hydraulic locking device for a press includes a connecting rod 1 with a stepped hole 10 and a screw 2 located in the stepped hole 10, the length of the screw 2 is such that it can extend outside the stepped hole 10, and the screw 2. The end protruding from the step hole 10 forms a screw ball head 21, which is connected to the slider 5. The improvement is that it also includes a lock nut 3 installed on the step hole 10. The lock nut 3 is installed so that Its top plane 31 has a certain axial clearance relative to the step 11. When the screw rod 2 and the lock nut 3 are screwed together, there is a certain thread clearance. The axial clearance is greater than this thread clearance. A sealing end cover 4 with a radial through hole 40 is fixedly installed on the bottom end surface, an axial separation cavity K is formed between the sealing end cover 4 and the lock nut 3, and the axial separation cavity K communicates with the radial thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com