Fine blanking machine upper die with adjusting device

A technology of adjusting device and fine blanking machine, which is applied in the direction of presses, metal processing equipment, forming tools, etc., can solve the problems of inability to achieve processing accuracy, low life, and inability to realize precise up and down movement adjustment of the upper mold, so as to achieve good practical use And promotion value, improving accuracy, simple and practical effect of structural improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

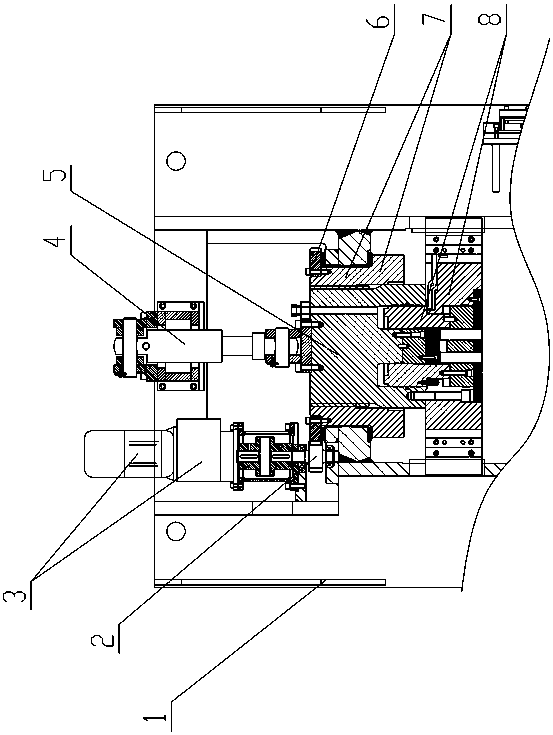

[0009] see figure 1 , the present invention is an upper die of a fine blanking machine with an adjustment device, which has an upper die body, the upper die body includes an upper die 5 and an upper die device 8, and an upper die adjustment device is connected with the upper die, and the upper die The adjustment device includes an upper mold lifting device and an upper mold balance locking device. The upper mold lifting device includes a nut sleeve 7 that is threadedly connected with the outer wall of the upper template, and a gear plate 6 is fixedly connected with the nut sleeve, and meshes with the gear plate A pinion 2 is connected, and the pinion is installed on the output end of the downwardly arranged lifting drive motor 3 connected to the top of the fine blanking machine body; the upper mold balance locking device includes a The balance locking oil cylinder 4 on the top of the fuselage is arranged downwards, and the piston rod of the balance locking oil cylinder is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com