Screw element, screw connection and method for producing screw element

A technology of threaded parts and screws, which is applied in the direction of connecting components, threaded fasteners, screws, etc., can solve the problems of uncompensated errors, damaged helix, and loose screws, etc., and achieve the effect of simplifying manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

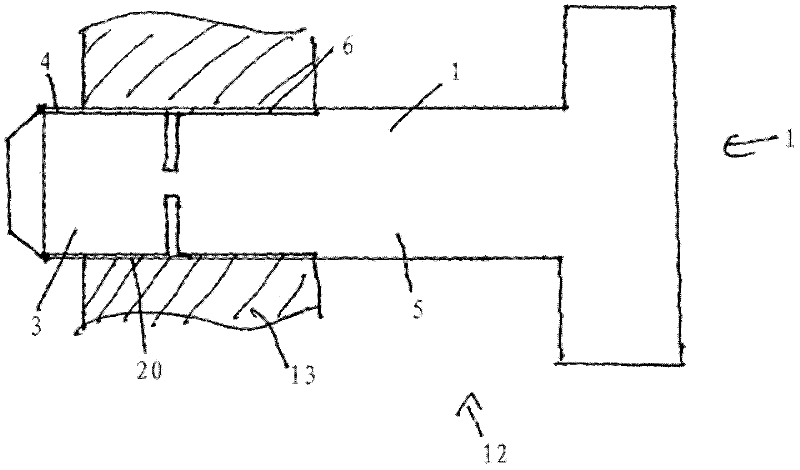

[0044] In the drawings, the same parts and parts with the same function are denoted by the same symbols.

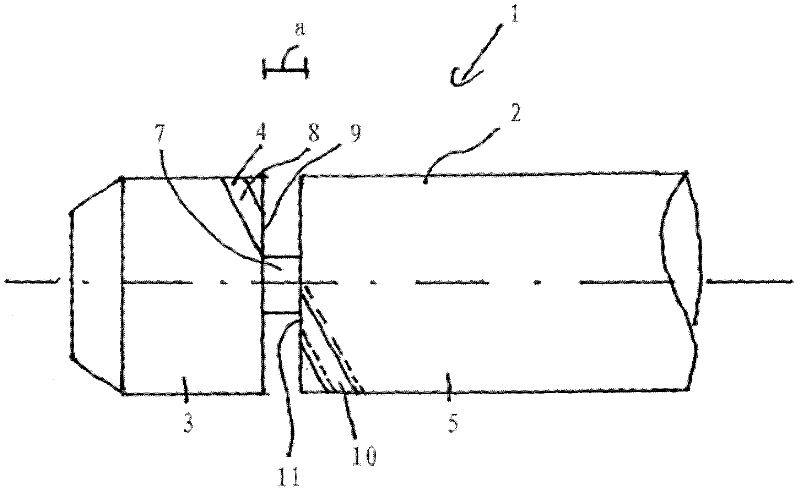

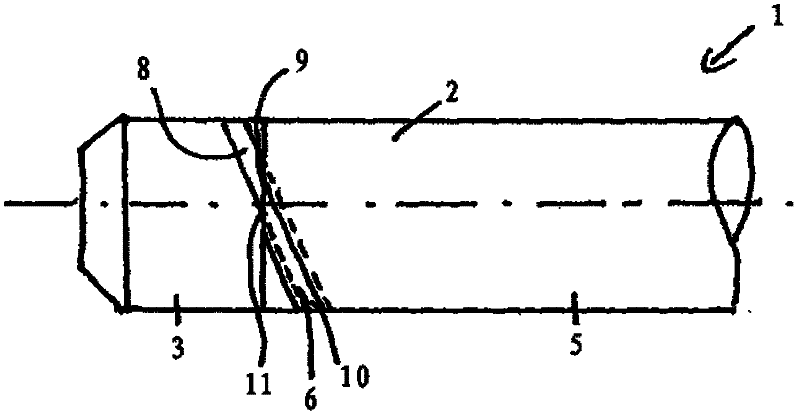

[0045] figure 1 Indicates part of the screw part 1. The screw part 1 comprises a shaft 2 which has a first external thread section 3 with a first external thread 4 on the end side. The second external thread section 5 is axially adjacent to the first external thread section 3 and is provided with a second external thread 6 . The two external threads 4, 6 are identical, ie they have the same course of the helix, the same pitch and the same thread size.

[0046] Depend on figure 1 It can be seen that the diameters (thread inner diameter and thread outer diameter) of the two external thread segments 3, 5 are consistent. Both externally threaded sections 3 , 5 are made on the integral rod 2 and are connected to each other (in one piece) by a cylindrical connecting section 7 . The connecting section 7 has a smaller diameter than the externally threaded sections 3, 5, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com