Automatic screw-driving machine with double electric screwdrivers and multiple feeders

An automatic locking screw machine and feeder technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low practicability and inconvenient use, so as to improve work efficiency, reduce production costs, and improve The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

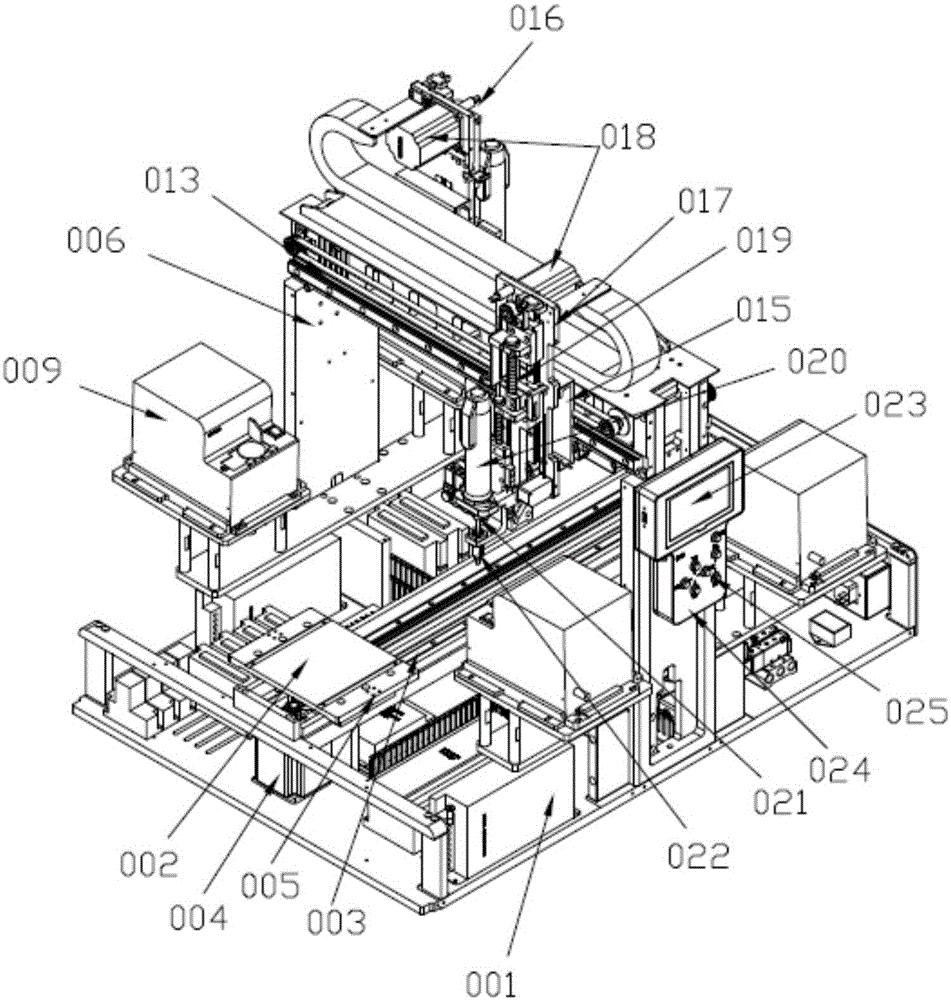

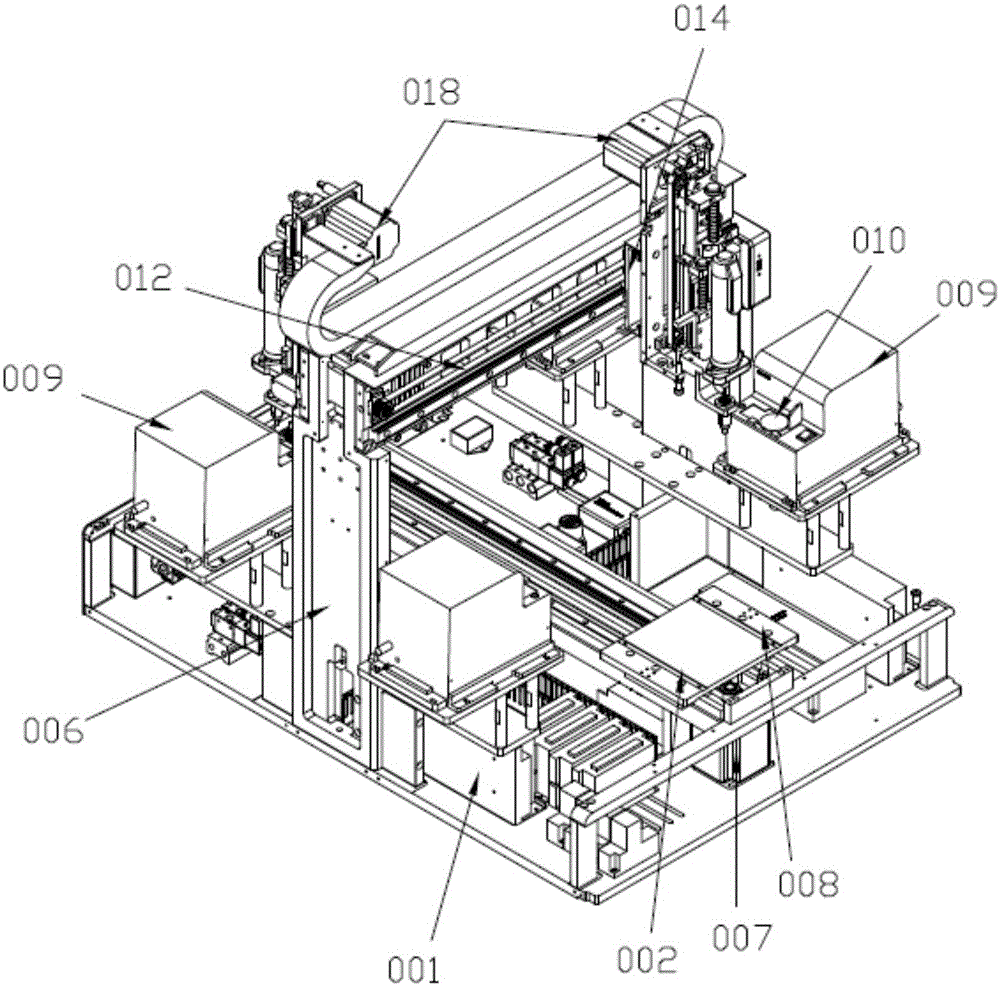

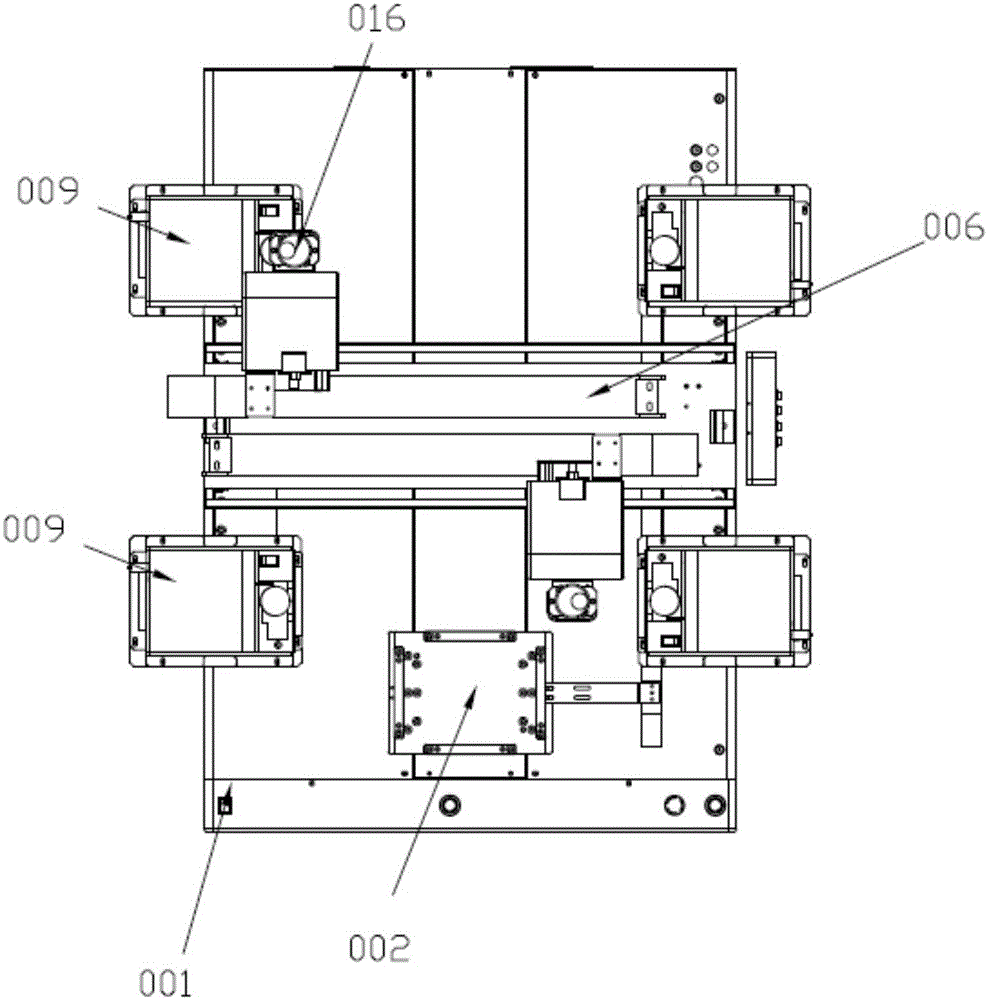

[0019] Figure 1 to Figure 4 It schematically shows a double electric batch multi-feeder automatic screw locking machine according to the present invention.

[0020] This embodiment provides a double electric batch multi-feeder automatic locking screw machine, please refer to Figure 1 to Figure 3 , including a machine base 001, a Y-axis moving mechanism is provided in the middle of the machine base 001, and two sets of clamps 002 are arranged on the Y-axis moving mechanism, specifically, the Y-axis moving mechanism includes The third linear slide rail 003 on 001, the first Y-axis stepping motor 004 and the second Y-axis stepping motor 007 with large torque, and the third linear slide rail 003 is provided with the Y-axis stepping motor 004. The third slider 005 and the fourth slider 008 connected with the Y-axis stepping motor 007, the two sets of clamps 00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com