Method and apparatus for cracking wall loose of conic cracker

A technology of cone crusher and crushing wall, which is applied in the direction of grain processing, etc., can solve the problems of crusher failure, compression nut loosening, etc., and achieve the effect of good anti-loosening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

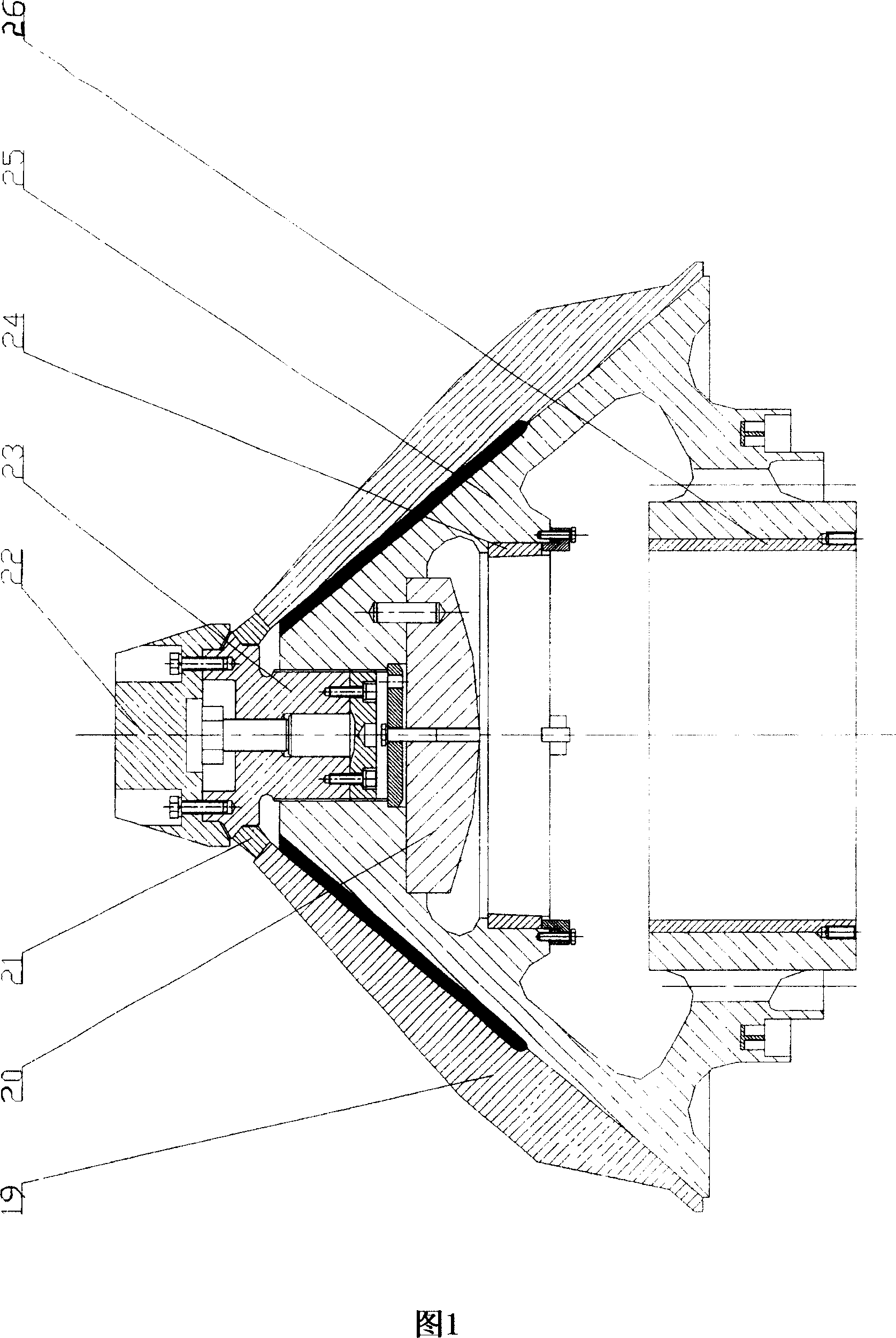

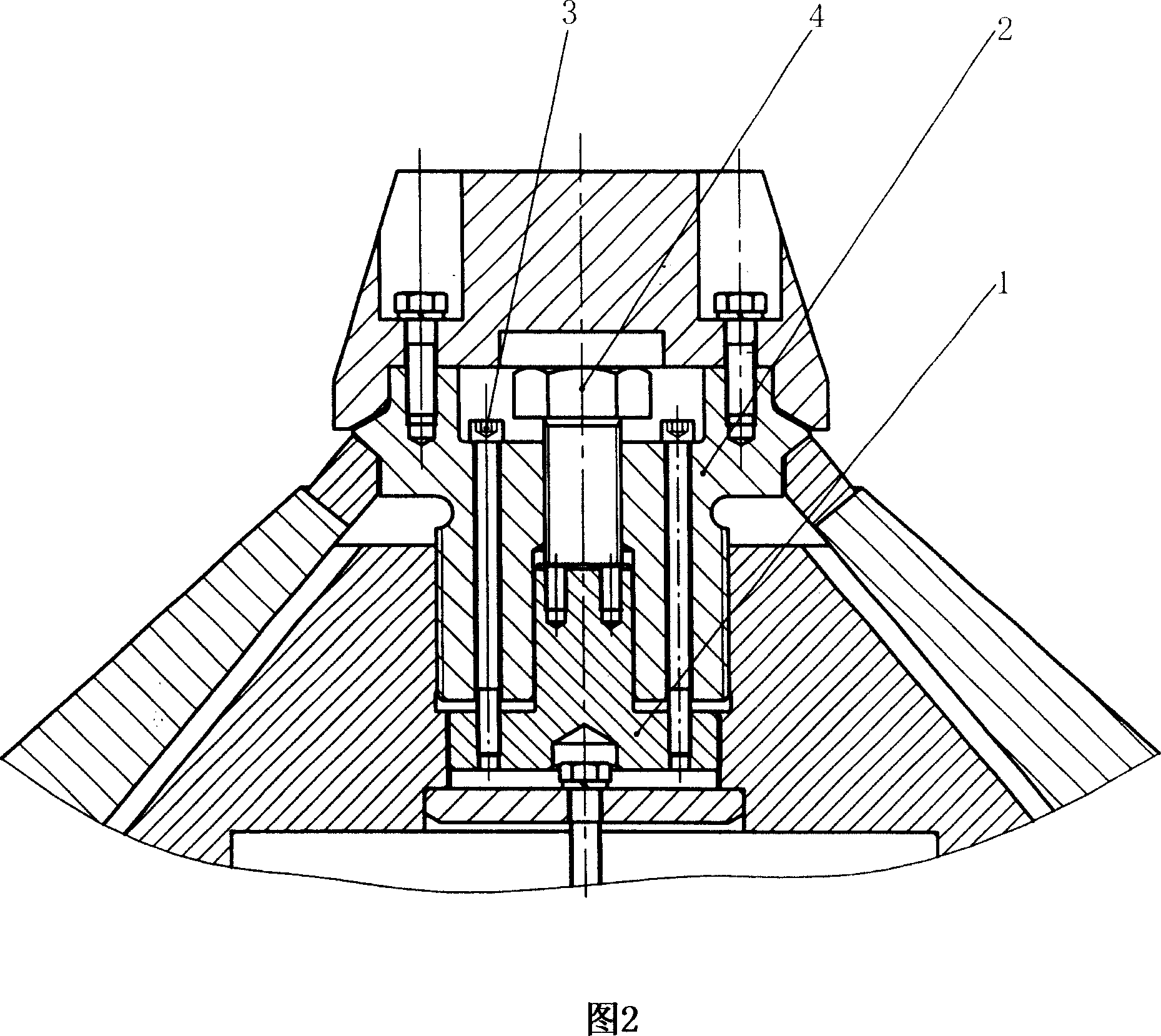

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and implementation.

[0013] As shown in Figure 2, the device for preventing the loosening of the broken wall of the cone crusher proposed by a preferred embodiment of the present invention includes a compression nut II2 with a large pitch and a large diameter, a compression nut I1 with a small pitch and a small diameter, and a compression nut II2 It is integrated with the compression nut I1 with a bolt 3; a jacking bolt 4 is arranged in the compression nut II2 for tightening the compression nut I1. The selection principle of the thread pitch in this embodiment is to use a thread with a smaller pitch as much as possible on the premise of meeting the thread strength requirements.

[0014] The method for preventing the broken wall of the cone crusher from loosening according to the present invention will be described below in conjunction with the accompanying draw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com