Flow guide disc installation method and installation device

An installation method and a technology for installation devices, which are applied in the direction of machines/engines, manufacturing tools, blade support elements, etc., can solve the problems of low installation quality and installation efficiency of the deflector plate, and the inability to achieve precise control of the installation size, etc., to ensure Accuracy, guaranteed installation quality, and improved installation quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered below.

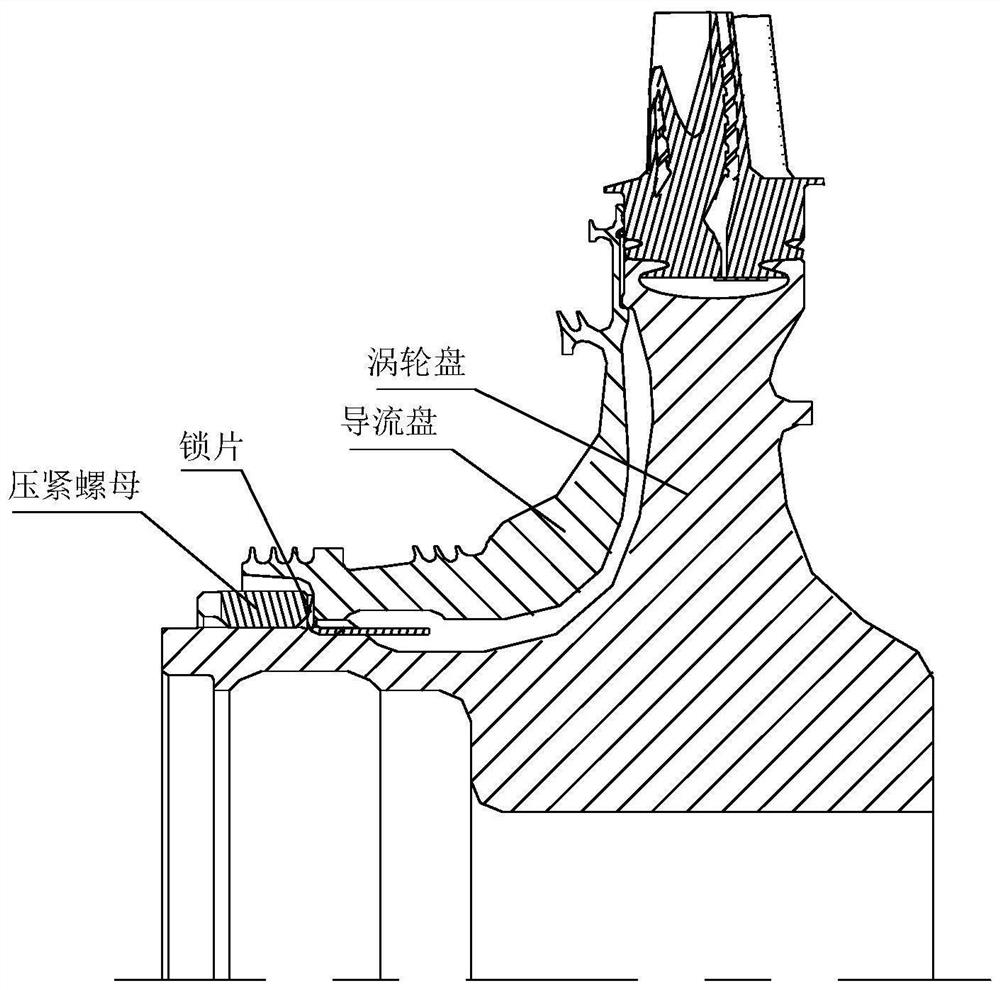

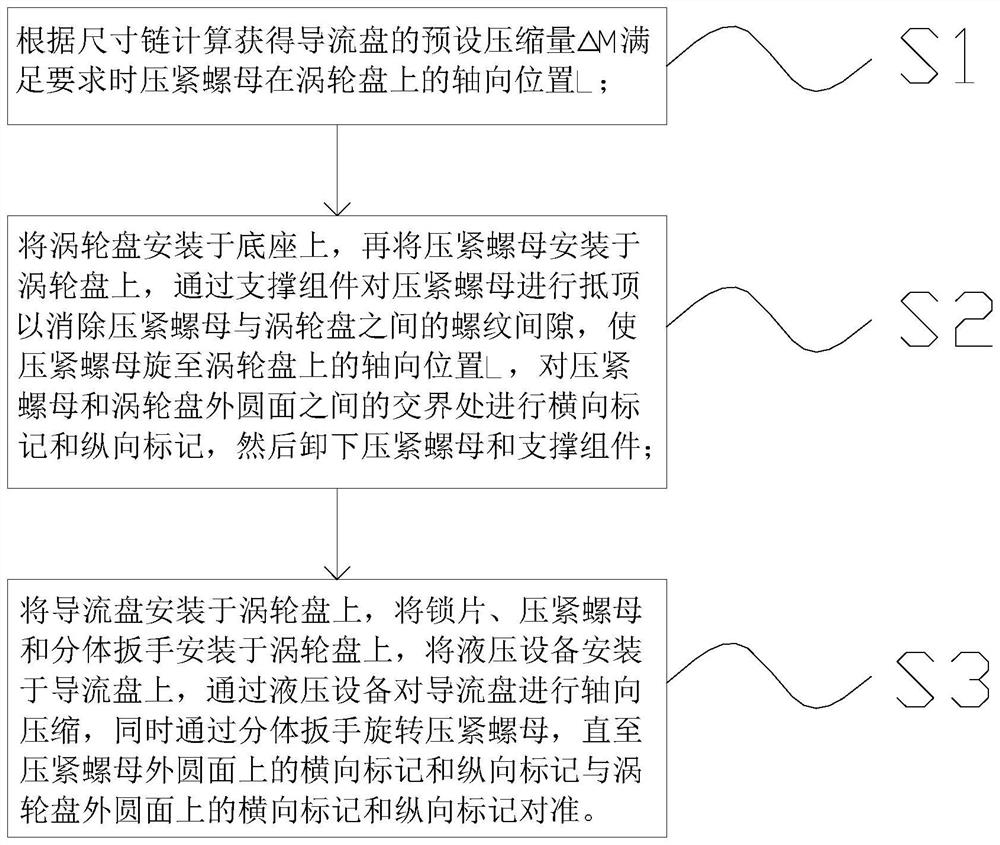

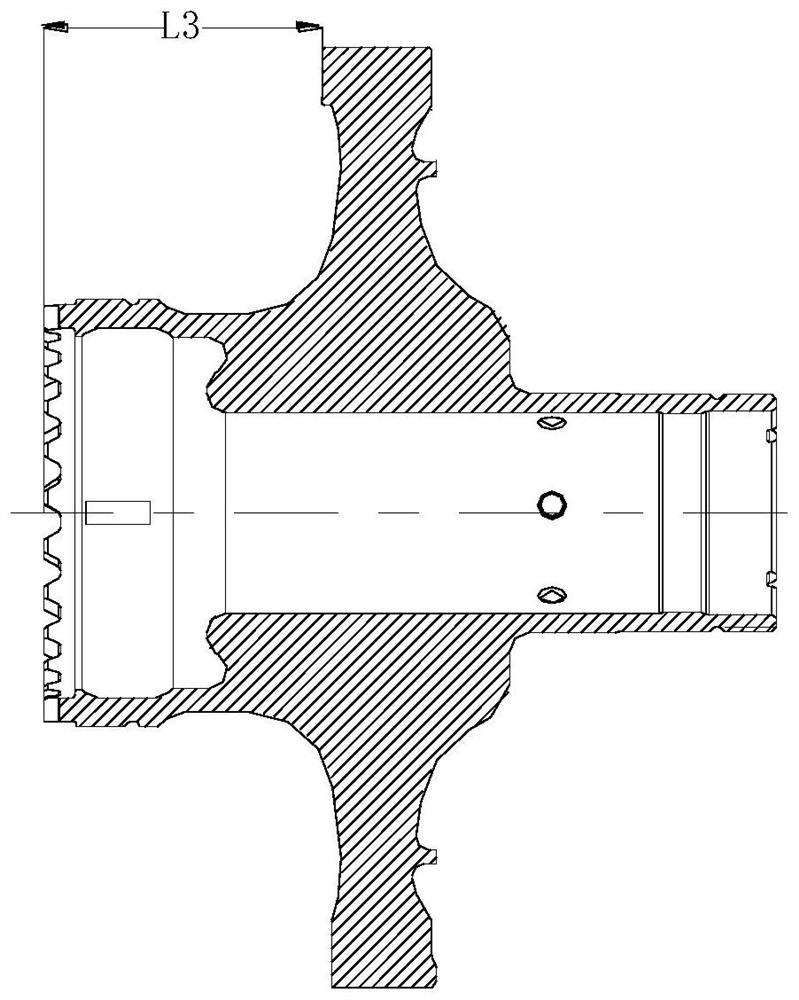

[0031] figure 1 It is a schematic diagram of the structure of the aero-engine gas turbine rotor; figure 2 It is a block diagram of the steps of the installation method of the guide plate according to the preferred embodiment of the present invention; image 3 It is a schematic diagram of the structure of the turbine disk in the rotor of the aero-engine gas turbine; Figure 4 It is a schematic diagram of the structure of the guide plate in the rotor of the aero-engine gas turbine; Figure 5 It is a schematic diagram of the structure of the connection between the guide plate and the turbine disk in the rotor of the aero-engine gas turbine; Image 6 It is a schematic structural diagram of the guide plate device according to the preferred embodiment of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com