A rotary screw sleeve for a fine-tuning boring unit

A technology for fine-tuning the boring tool and screw sleeve, applied in the direction of the boring head, etc., can solve the problems such as the inability to assemble the product, the loss of the transmission accuracy of the thread transmission, and the difficult deformation amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

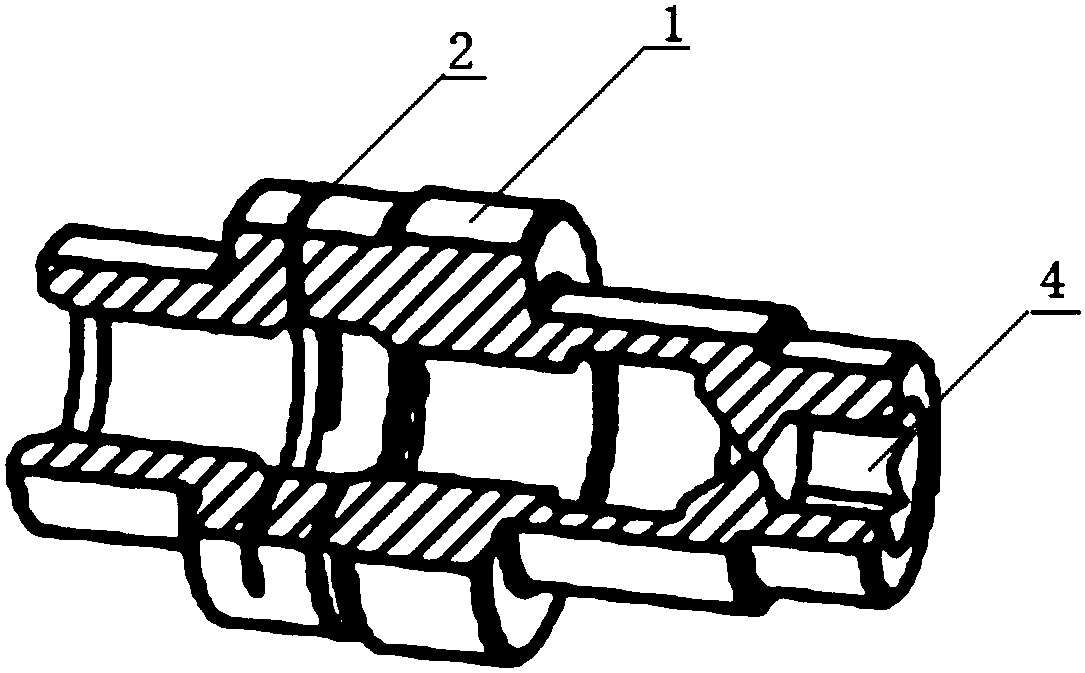

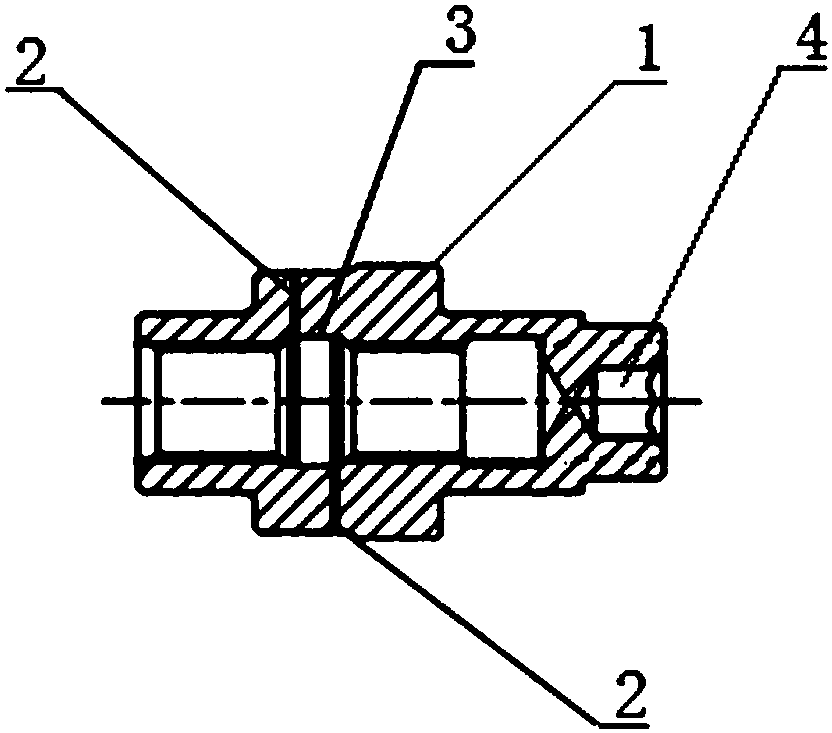

[0020] Such as figure 1 As shown, the rotary screw sleeve of the fine-tuning boring unit disclosed in this embodiment has an annular boss 1 on the outer peripheral surface of the rotary screw sleeve, and a narrow groove 2 is radially opened on the outer cylindrical surface of the annular boss 1, and the narrow groove 2 The depth is greater than the radius of the outer cylindrical surface; an empty knife groove 3 is set in the rotary screw sleeve to divide the internal thread hole of the rotary screw sleeve into two sections; the narrow groove 2 is located at the empty knife groove 3, and there are two narrow grooves 2 , the two narrow grooves 2 are axially staggered, and the opening directions of the two narrow grooves 2 differ by 180 degrees. The internally threaded hole of the rotary screw sleeve is a blind hole, and one end of the rotary screw sleeve is axially provided with a hexagonal wrench 4, and the outer circumferential surface at the 4 places of the rotary screw slee...

Embodiment 2

[0022] The difference between this embodiment and Embodiment 1 is that the depth of the narrow groove 2 is equal to the sum of the radius of the outer cylindrical surface and the radius of the empty sipe 3 .

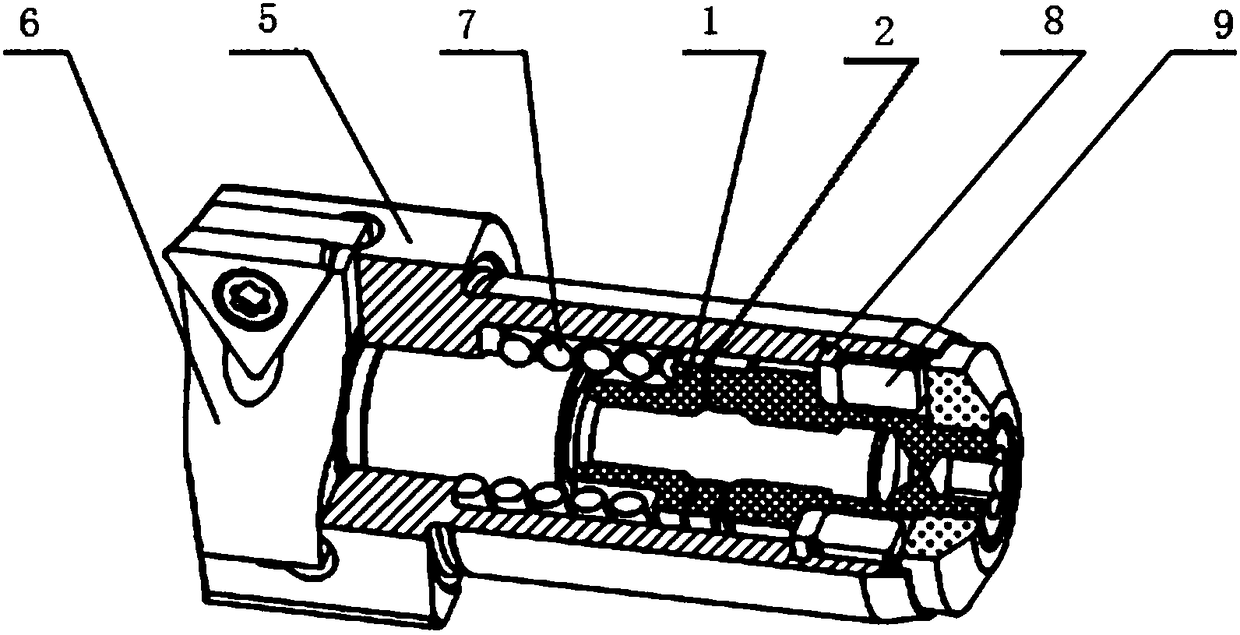

[0023] Such as image 3 As shown, the present invention is coaxially installed in the outer sleeve 5, and one end of the knife rod 6 is installed in the internal threaded hole of the present invention through threads, and the spring 7, the limit flat washer 8 and the lock nut 9 are all sleeved on the present invention. , the lock nut 9 is threadedly connected with the outer sleeve 5; one end surface of the annular boss 1 is pressed against the limit flat washer 8, and the other end surface of the annular boss 1 is pressed against the spring 7, and the limit flat washer 8 is under pressure In the locking nut 9, the spring 7 is pressed on the inner step surface of the outer sleeve 5, and the outer side of the locking nut 9 is provided with an end cover, which is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com