Depressing and balancing device for steel section straightener

A technology of a balancing device and a pressing device, which is applied in the field of metallurgical equipment, can solve the problems of large bouncing of steel straightening machines, poor straightening effect of profiles, and difficulty in automation, and achieves the effects of improving work efficiency, facilitating maintenance, and being easy to automate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

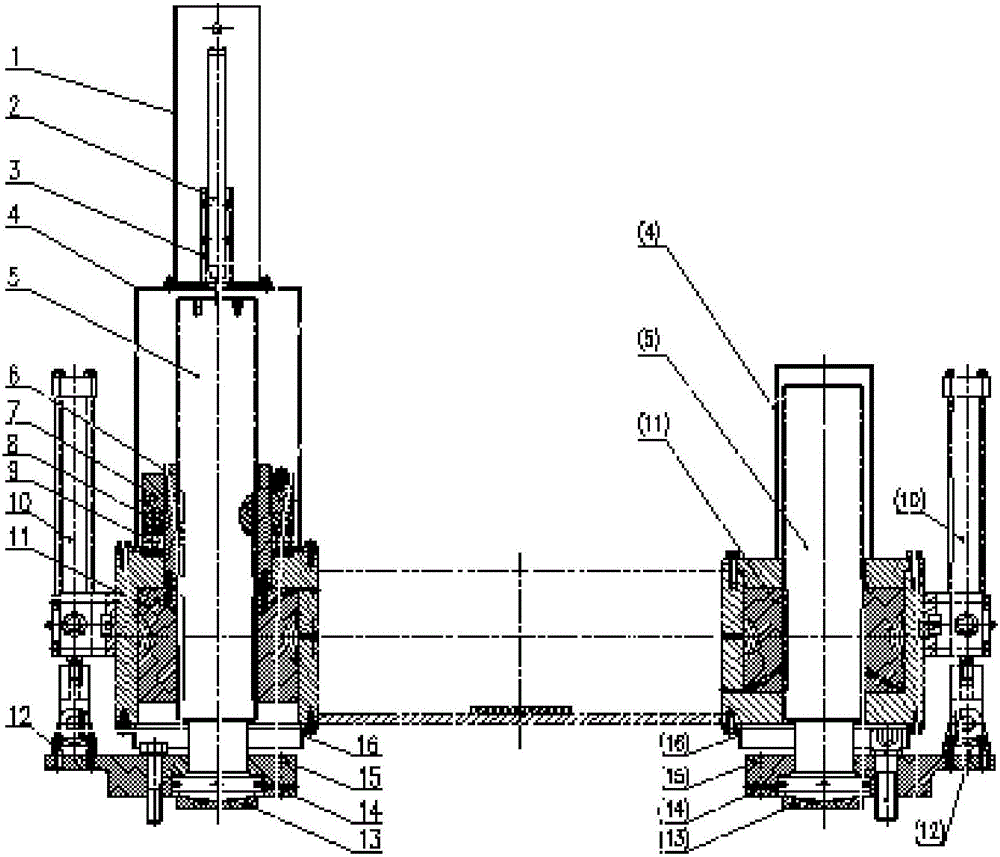

[0017] Such as figure 1 and figure 2 As shown, the profile steel straightening and pressing and balancing device of the present invention includes two sets of pressing devices with pressing screws 5, a driving device for driving the pressing screws 5 up and down, and a driving device for adjusting the pressing screws. the adjustment device;

[0018] Described depressing device comprises worm gear 11, and described worm gear 11 is vertically, rotatably arranged inside the frame box body, and the inner side of described worm gear 11 is threadedly connected with described depressing screw 5;

[0019] The driving device includes a geared motor 19, which is arranged in the middle of two groups of pressing devices; the geared motor is connected with the worm gear to drive the worm gear to rotate;

[0020] The adjusting device includes a hydraulic cylinder, the housing of which is fixed on the outside of the frame box, and the hydraulic cylinder is arranged vertically and parallel...

Embodiment 2

[0023] As a further improvement of the first embodiment, the device further includes a displacement sensor 2, which is arranged on the top of the pressing screw to detect the moving distance of the top of the pressing screw. Specifically, a protective cover 4 is provided on the pressing screw 5, a protective cover 1 is provided on the displacement sensor 2, and the sensor bracket 3 is connected with the protective cover and the protective cover of the left pressing device through bolts or the like. The protective cover is connected with the upper part of the rack box body through bolts.

Embodiment 3

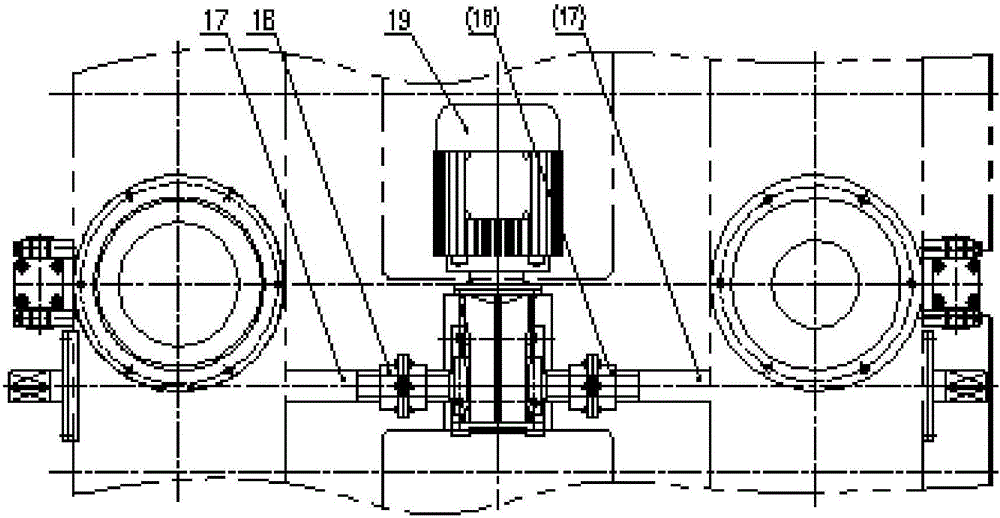

[0025] As a further solution of the above-mentioned embodiments, the geared motor 19 includes a reducer and a motor; the reducer includes an input shaft and two output shafts, the input shaft of the reducer is connected to the output shaft of the motor, and the The two output shafts of the speed reducer are respectively connected with the sleeves in the two sets of pressing devices, and drive the sleeves to rotate.

[0026] Working principle of the present invention is:

[0027] The left and right worm shafts 17 are fixedly installed on the upper part of the frame box, and are connected synchronously through the coupling 18 respectively. Driven by the geared motor, the left and right worm shafts 17 rotate synchronously, driving the left and right worm gear pairs to rotate synchronously, and the left and right worm gear pairs are internally threaded. Down, left and right press the screw to move up or down, and the lower part of the left and right press screw is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com