Levelling device and levelling method for polishing head

A leveling device and polishing head technology, which is applied in the direction of grinding devices, grinding machine tools, metal processing equipment, etc., can solve the problems of small wafer size, high cost, and large volume of leveling devices, so as to eliminate thread gaps and improve vertical degree, improve the effect of leveling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

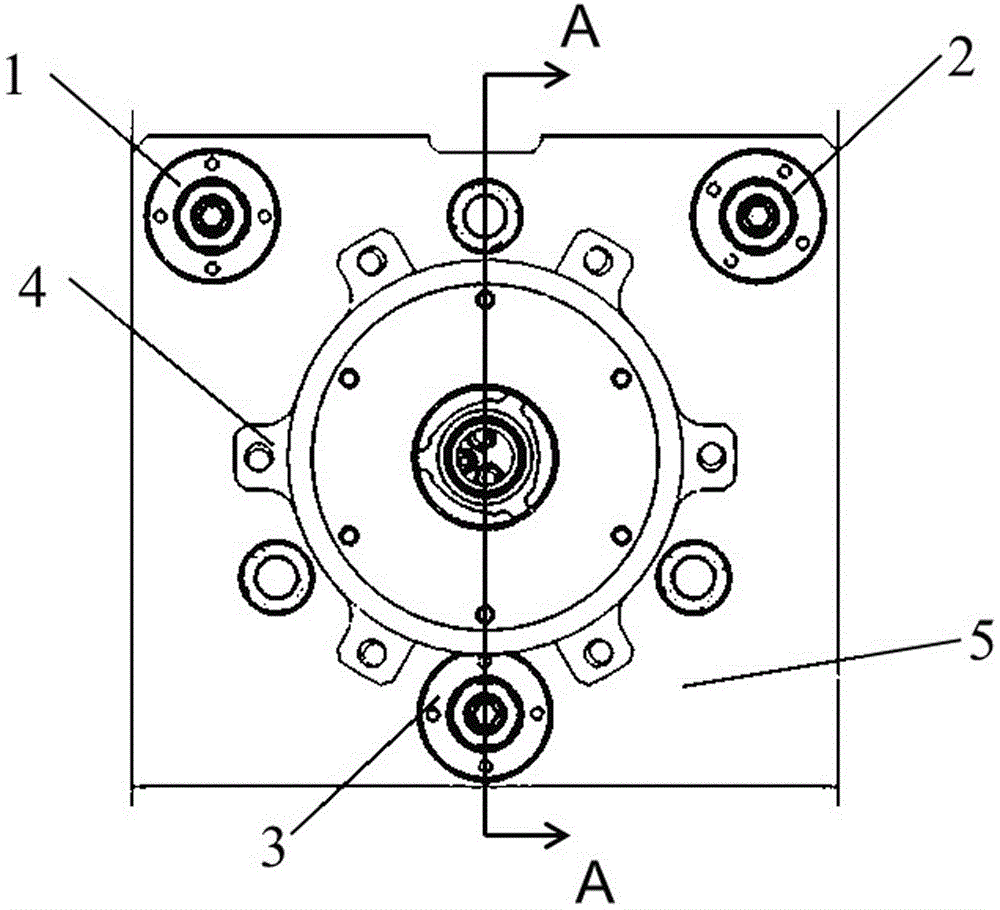

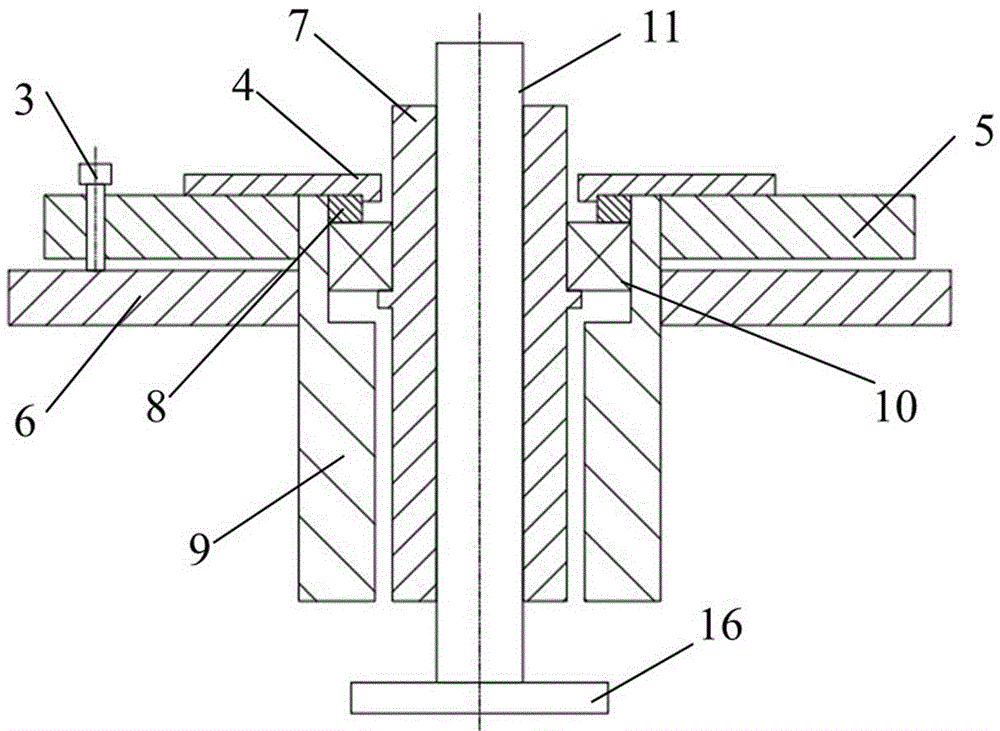

[0027] like Figure 1-3 As shown, the adjustment plate 5 is adjusted by the adjustment screw group 1, the adjustment screw group 2 and the adjustment screw group 3, according to the principle of determining a plane at three points, such as fixing the position of the adjustment screw group 1, adjusting the adjustment screw group 2 adjust the height of adjusting screw group 1 and adjusting screw group 2 in a horizontal state; adjust the height of adjusting screw group 3 so that adjusting screw group 1 and adjusting screw group 3 are in a horizontal state; when adjusting screw group 1, adjusting screw group 2 and the adjusting screw group 3 are rigidly connected to each other, then the adjusting plate 5 is in a horizontal state at this moment.

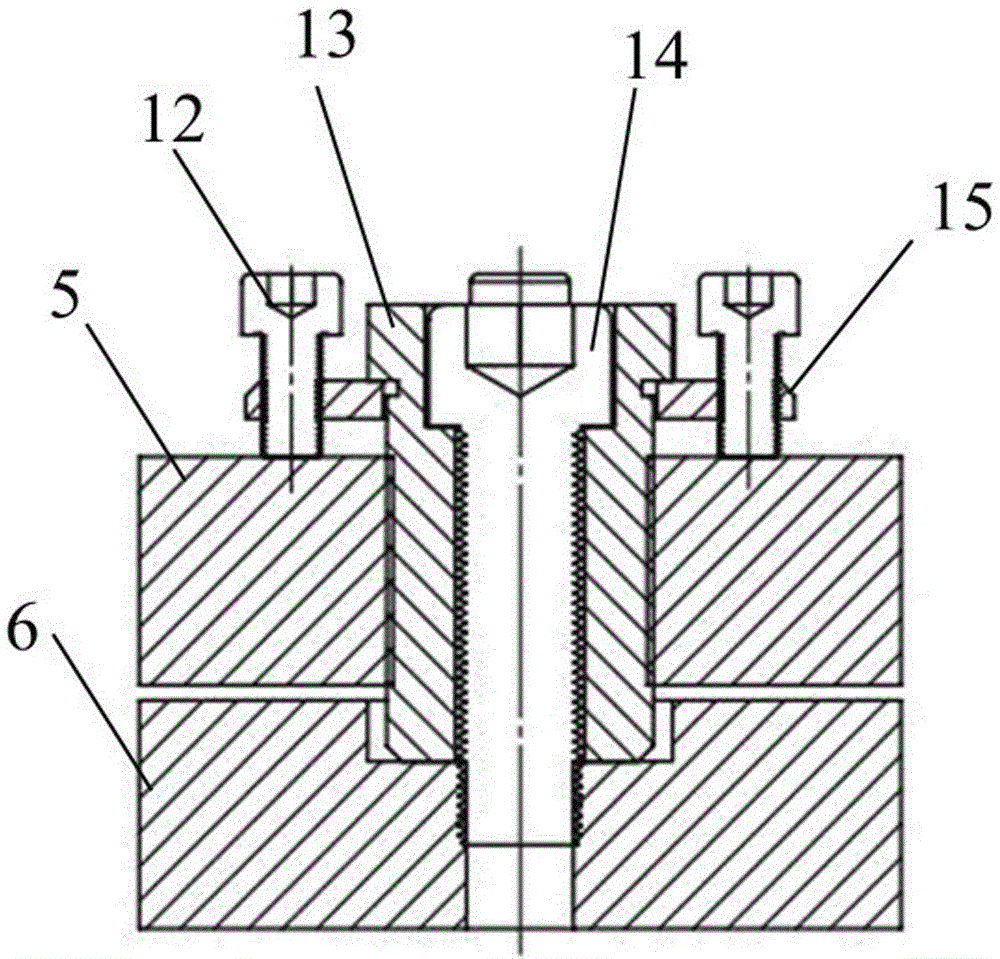

[0028] The adjusting plate 5 is placed on the horizontal base plate 6, the bearing 10 is placed betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com