Optical module and camera module

A technology of optical modules and optical parts, which is applied to cameras, focusing devices of cameras, optics, etc., can solve the problems of changing the shape of the lens driving device, no freedom of shape design, and no freedom of shape design of stepping motors, and achieves the suppression of Power loss, the effect of ensuring movement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

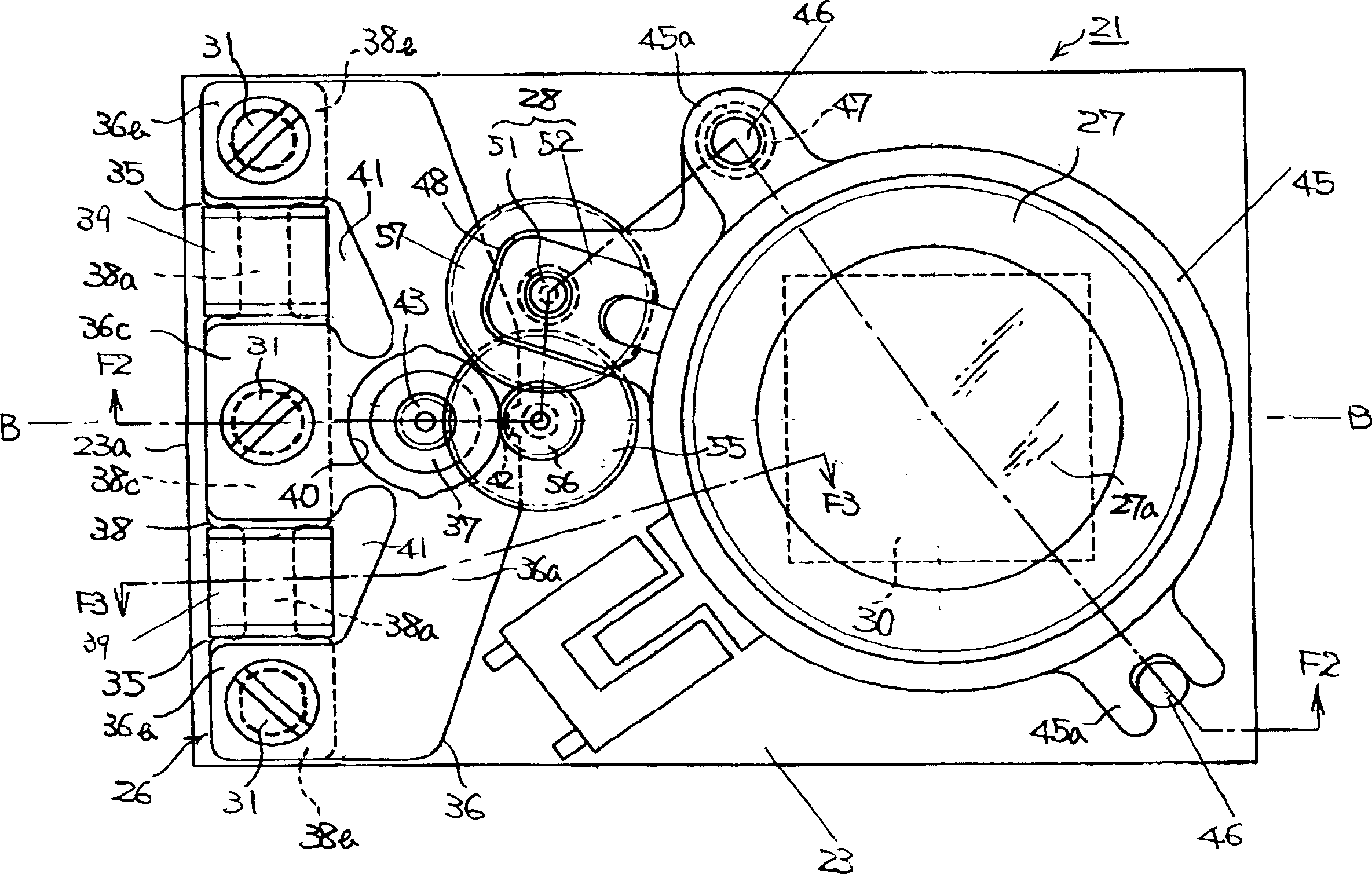

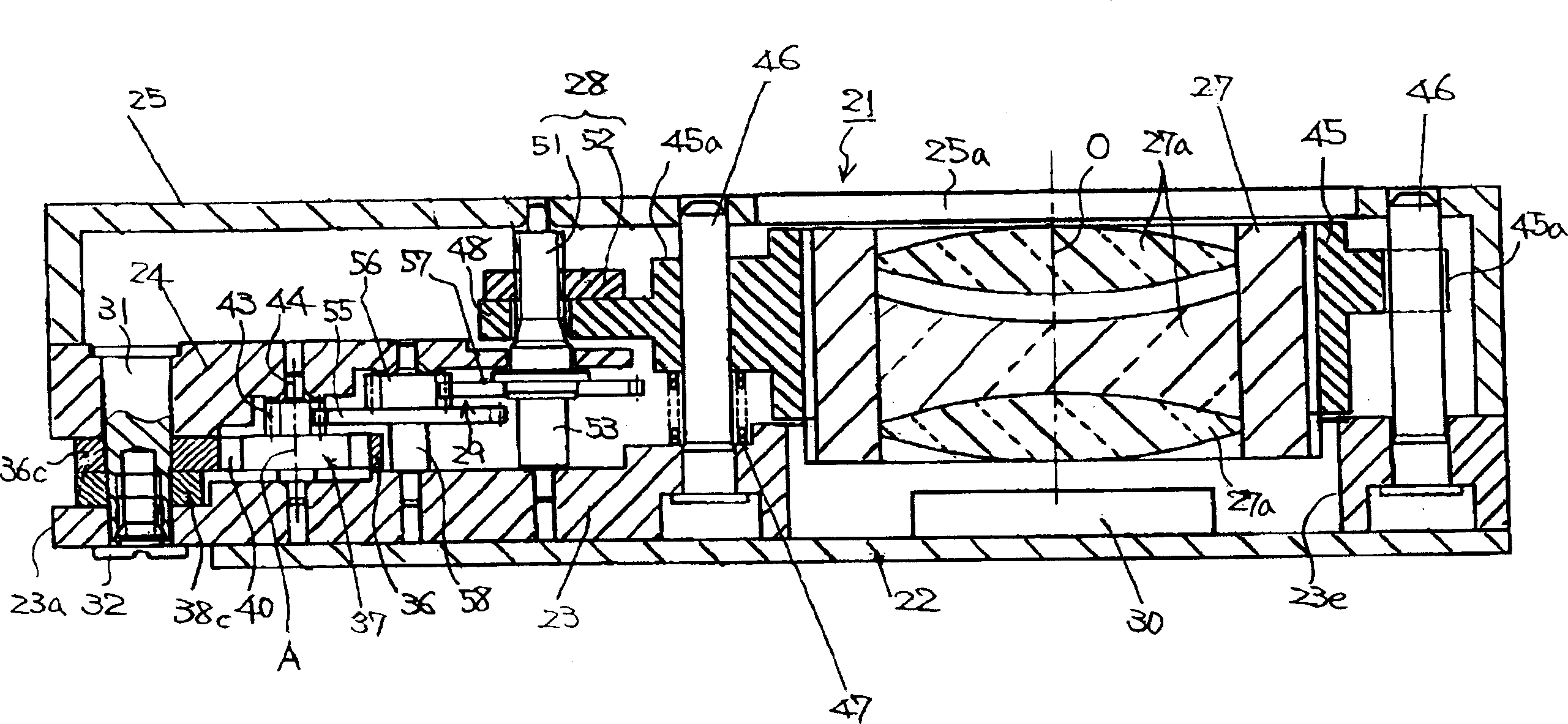

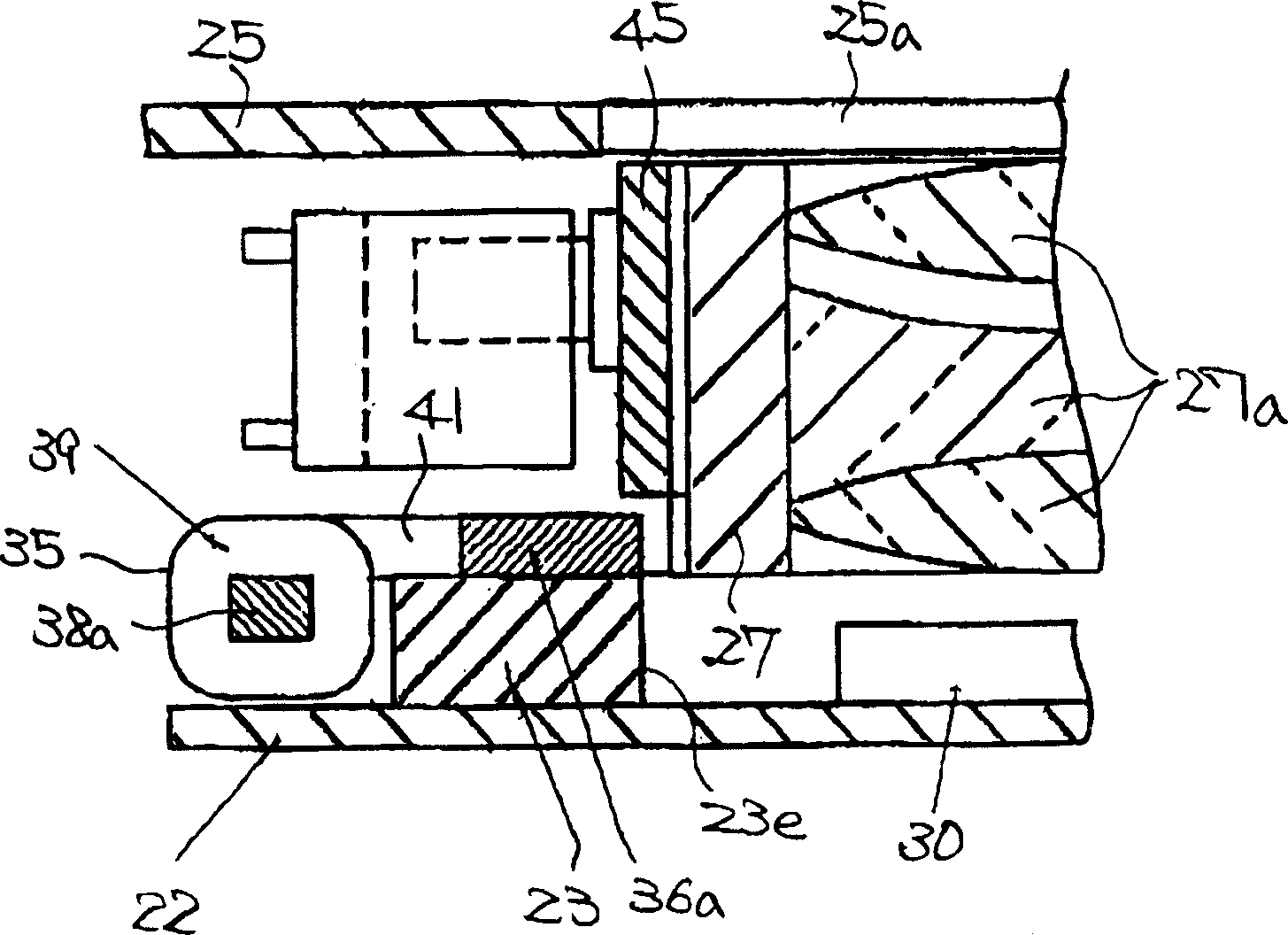

[0050] refer to Figure 1 to Figure 4 The first embodiment of the present invention will be described.

[0051] figure 1 and figure 2 An optical module denoted by reference numeral 21 , for example, a lens driving device, is mounted on a thin electronic device such as a card-type digital camera or a mobile phone with a camera function. This lens driving device 21 includes: a circuit board 22, a bottom plate 23, a gear holder 24, a cover 25, a stepping motor 26, optical components such as a lens barrel 27, a moving mechanism 28, and a reduction gear train 29 as a gear train.

[0052] The circuit board 22 is a hard plate, and an imaging element 30 such as a CCD or CMOS is mounted on one surface thereof. A bottom plate 23 is bonded to the above-mentioned one surface of the circuit board 22 . The bottom plate 23 has a rectangular shape, for example, and has a hole 23e at one end in the longitudinal direction for accommodating the imaging element 30 and allowing the lens barr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com