Wire driven parallel unmanned agricultural robot and control method thereof

A robot and cable technology, which is applied in the control field of unmanned agricultural robots, can solve the problems of low degree of automation of ground operations and low accuracy of aerial operations, so as to ensure the stability and accuracy of movement, improve stability, and reduce inclination. Effects of Torsion Error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

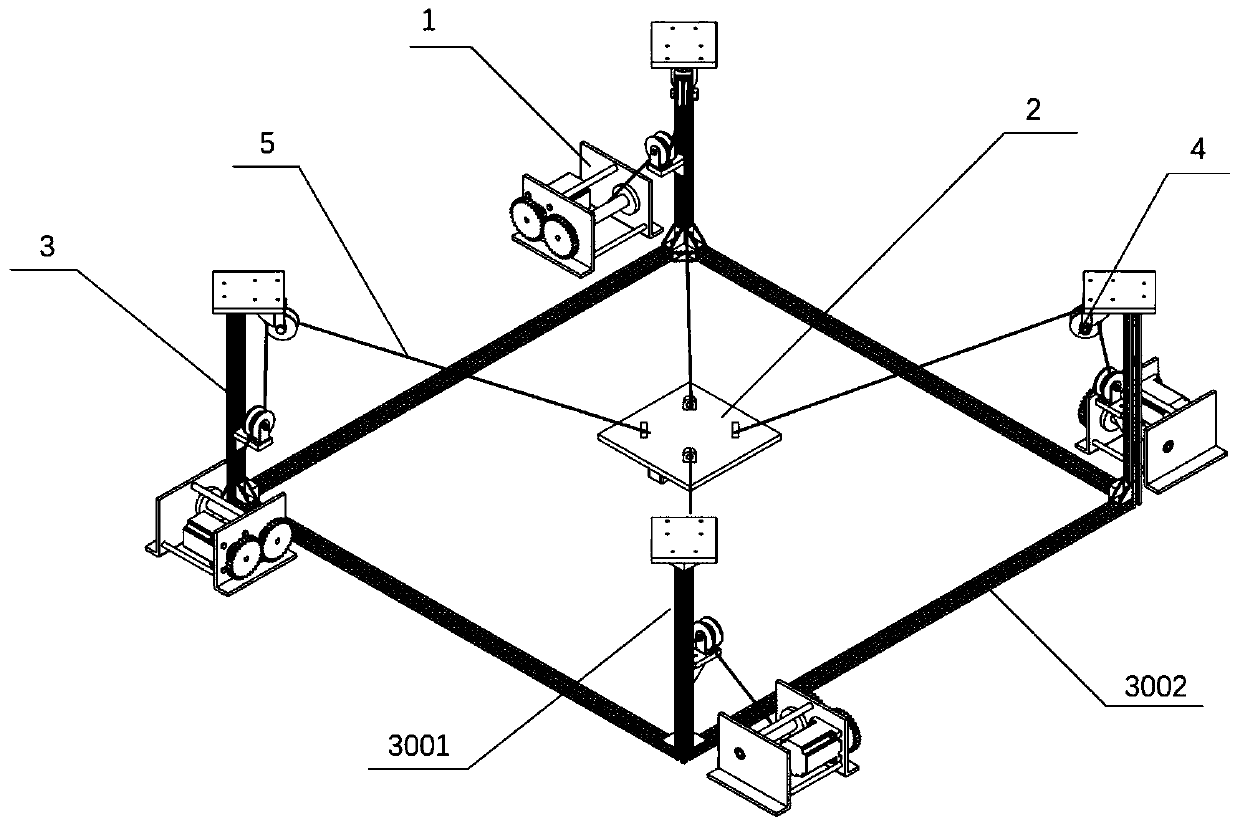

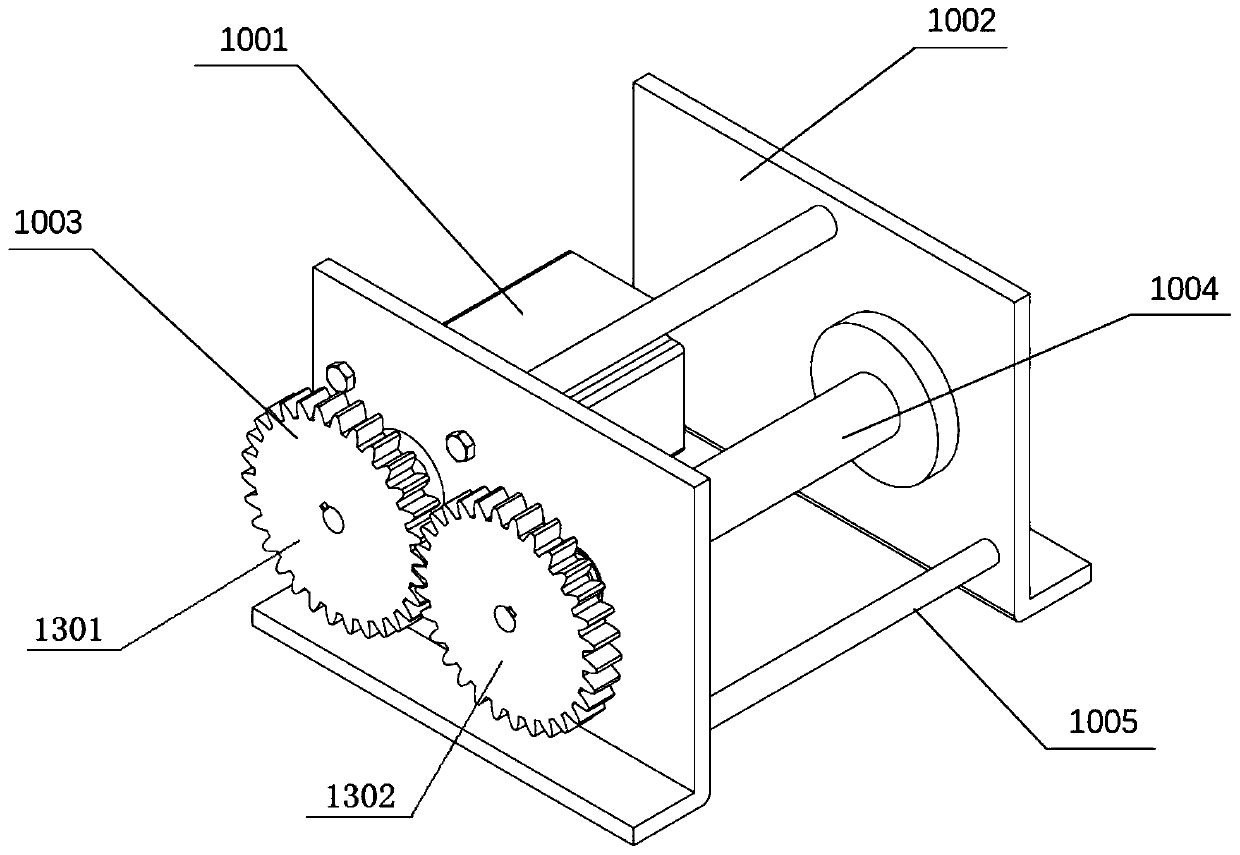

[0045] see Figure 1-7 , the present embodiment provides an unmanned agricultural robot driven in parallel by cables, and the robot is used for hoisting at least one agricultural equipment. The unmanned agricultural robot provided in this embodiment takes the four-cable parallel structure as the basic structure, and realizes the platform movement by controlling the expansion and contraction of the flexible cables for operation. In this embodiment, the unmanned agricultural robot includes a mobile platform 2, a tower system, a winch system 1, a cable 5, an ultrasonic module and a control system. Among them, the number of flexible cables 5 is at least four, and the mobile platform 2 is driven in parallel.

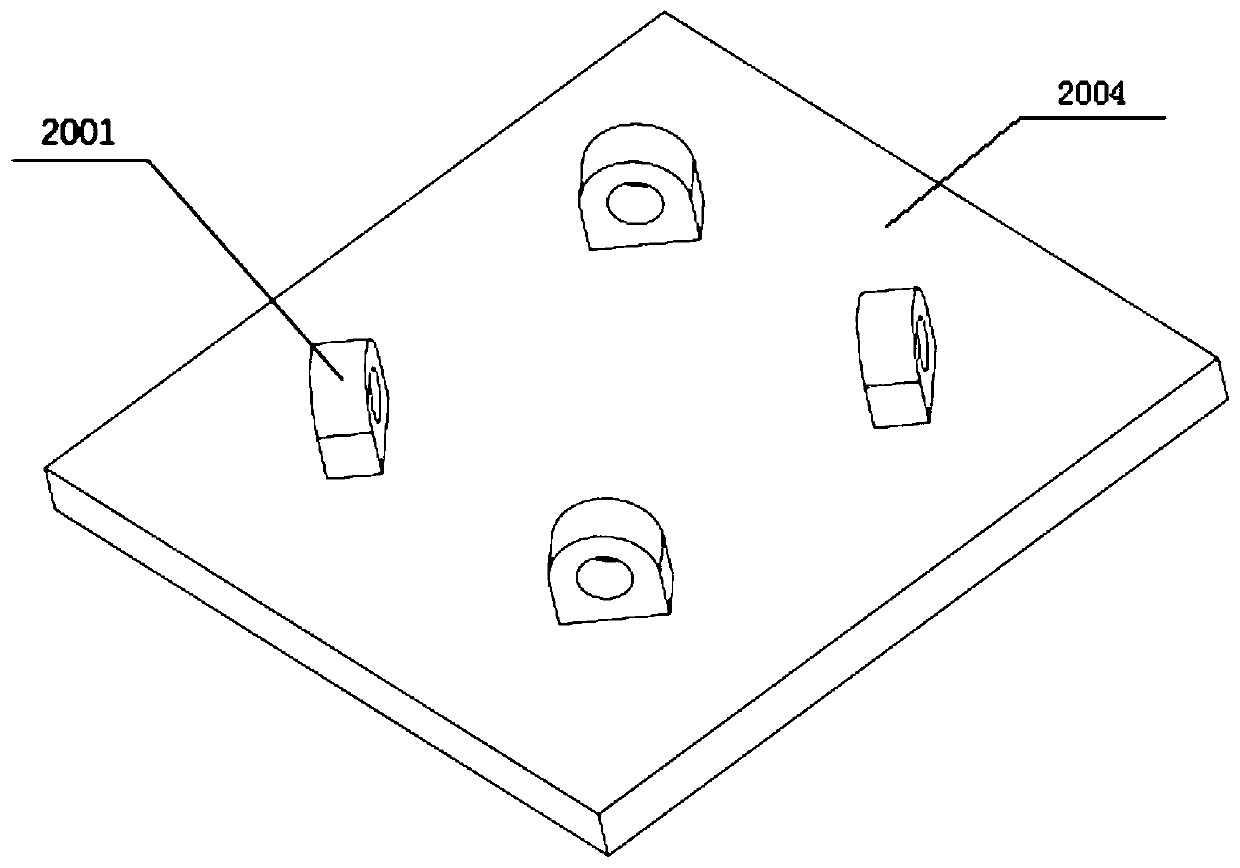

[0046] read on image 3 and Figure 4 , the mobile platform 2 includes a workbench 2004 and an automatic hook and lock device 2003 , and in this embodiment, the mobile platform 2 may further include a rope fixing part 2001 and a camera device 2002 . In this embodiment, th...

Embodiment 2

[0062] This embodiment provides an unmanned agricultural robot driven in parallel by cables, which adds some control functions of the control system on the basis of Embodiment 1. Among them, the control system is used to start the camera device 2002 to collect the image information of the agricultural equipment when the workbench 2004 is located above the agricultural equipment; Search and extract preset equipment features whose feature similarity reaches a preset ratio, then obtain the equipment information of agricultural equipment according to the preset equipment features, and finally drive the winch system 1 to adjust the position of the workbench 2004 according to the equipment information, so that The automatic hook lock device 2003 can be aligned with the hook lock parts of the agricultural equipment.

[0063] In this embodiment, the control system can extract the features of the image according to the collected image information, and then compare the extracted feature...

Embodiment 3

[0065] This embodiment provides an unmanned agricultural robot driven in parallel by flexible cables, which adds an alarm system and a detection system on the basis of Embodiment 1. Wherein, the detection system includes a ranging sensor. The ranging sensor is installed on the workbench 2004 and is used to detect the real-time distance between the agricultural equipment and the workbench 2004 when the workbench 2004 is located above the agricultural equipment. The control system is also used to judge whether the real-time distance is less than a preset distance. When the real-time distance is less than the preset distance, the control system drives the alarm system to send out an alarm message. In this way, when the distance between the workbench and the agricultural equipment is too small, the alarm system will send out an alarm message, so that the hoisting process can be stopped in time, preventing the mobile platform from smashing the agricultural equipment or the agricul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com