Portable cantilever-type numerical control cutter

A cantilever type, cutting machine technology, applied in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve the problems of unsatisfactory lateral movement accuracy and running balance, easy to wear gaps on contact surfaces, affecting longitudinal movement accuracy, etc. , to achieve the effect of high longitudinal movement accuracy, improved cutting accuracy, and improved lateral movement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

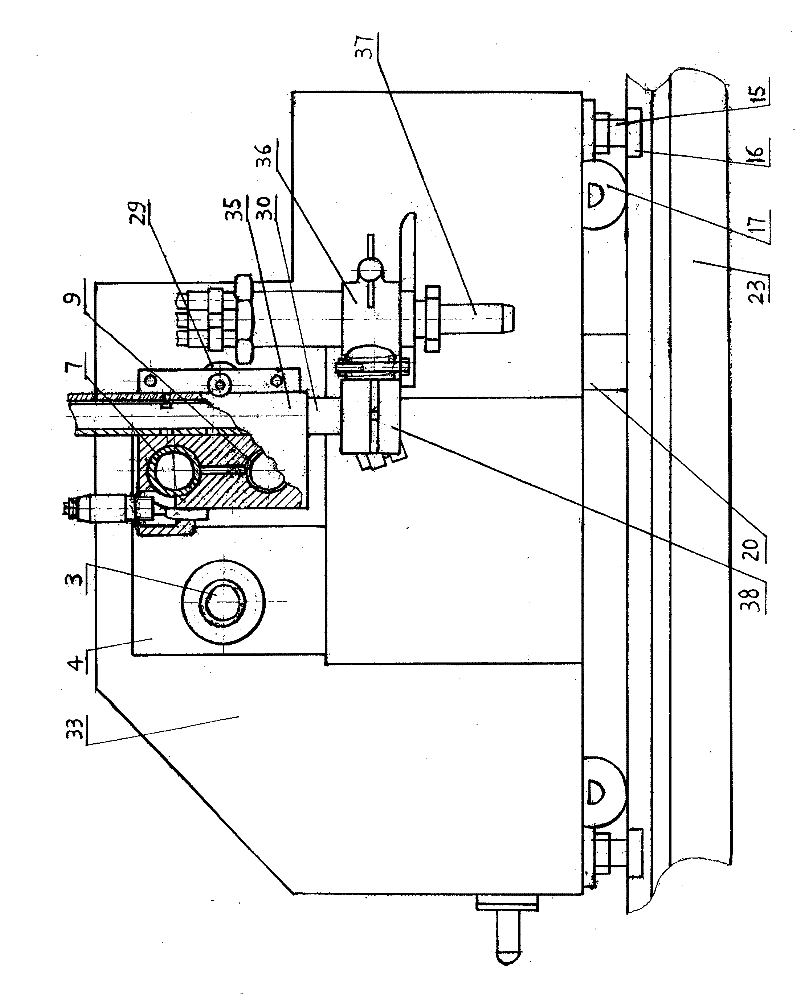

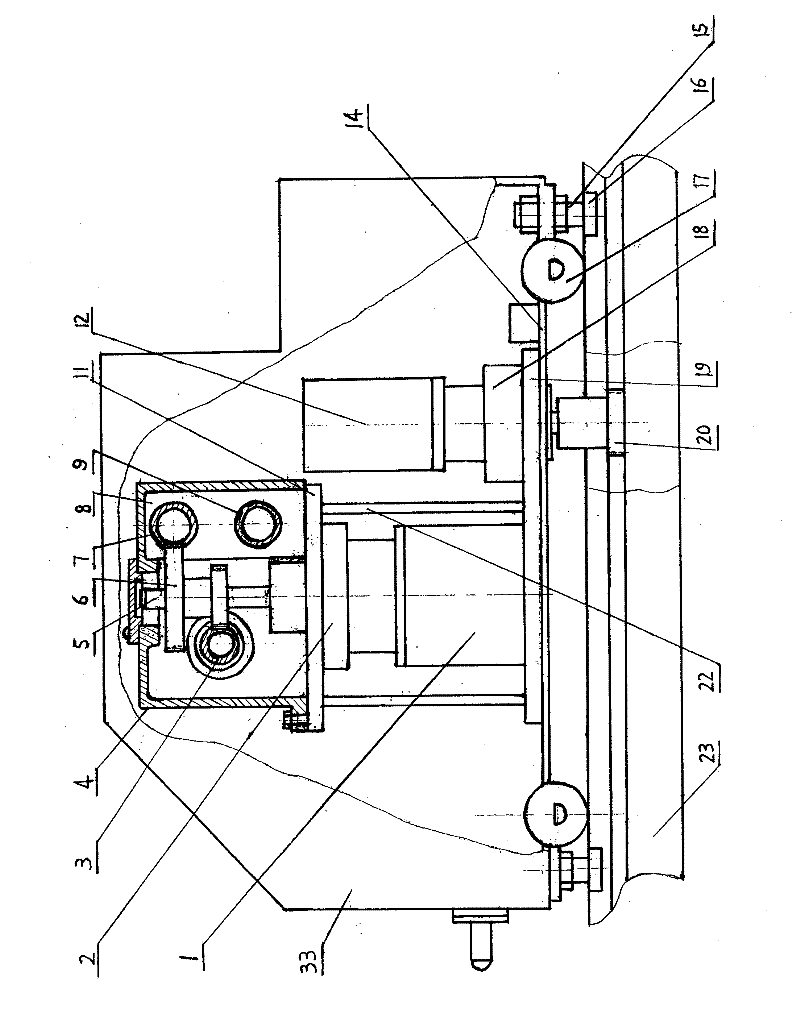

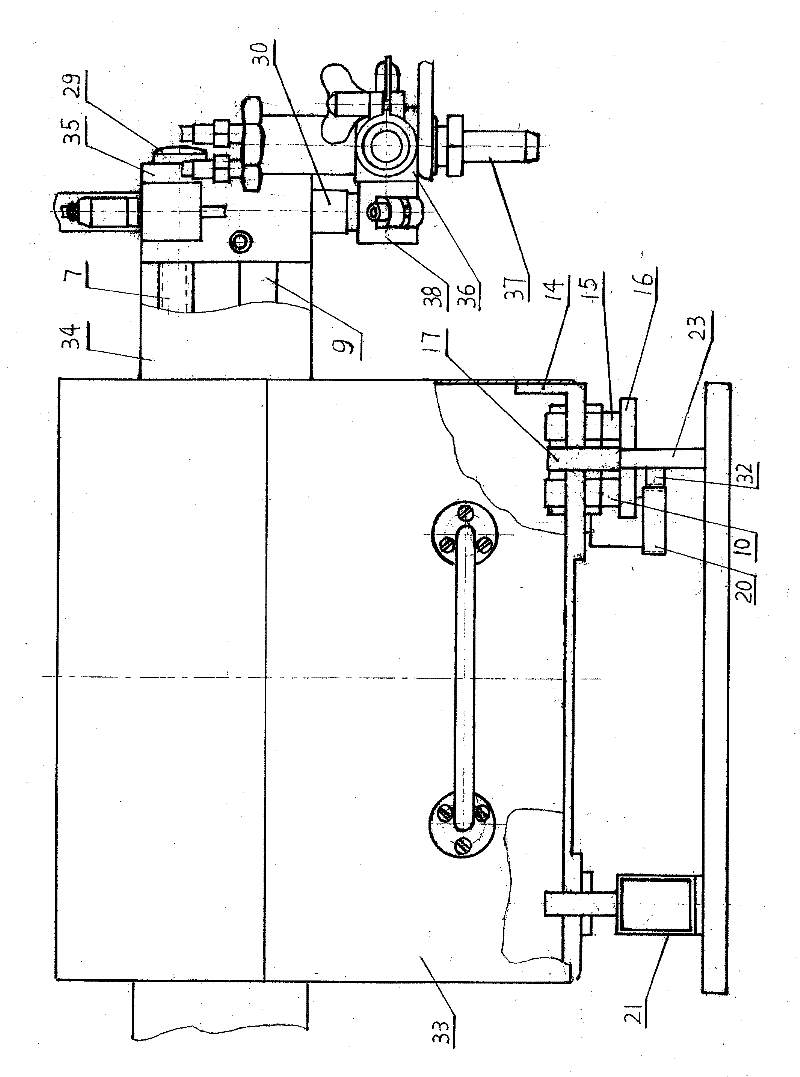

[0022] As shown in the figure, the present invention includes a mobile trolley 33 and a numerical control device. The mobile trolley 33 is seated on the mutually parallel guide rails 23 and support rails 21 through four rollers 17. The difference is that the horizontal stepping motor 1 is fixedly connected Transverse planetary gear reducer 2, the transverse planetary gear reducer 2 is installed in the slot hole of the frame plate 11 on the upper part of the frame 22, the frame 22 is fixed on the bottom plate 14 of the trolley, and the horizontal support 4 is fixedly connected above the frame plate 11, A balance rack bar 3 is sheathed in the guide hole in the front and rear wall middle of the left half of the transverse support 4, and a transverse seat block 8 is fixed on the right half of the transverse support 4 with screws, and the upper and lower guide holes of the transverse seat block 8 are respectively There are laterally moving rack bars 7 and lateral guide rods 9 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com