Full-automatic double-bag packaging ORABS system for sterile inner bags

A fully automatic, double-bag technology, applied in the directions of automatic packaging control, packaging, transportation packaging, etc., can solve the problems that the drug packaging process cannot be automated, does not conform to the long-term development of the enterprise, and is inconvenient to operate, so as to improve the handling efficiency and realize Effects of automation and life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings.

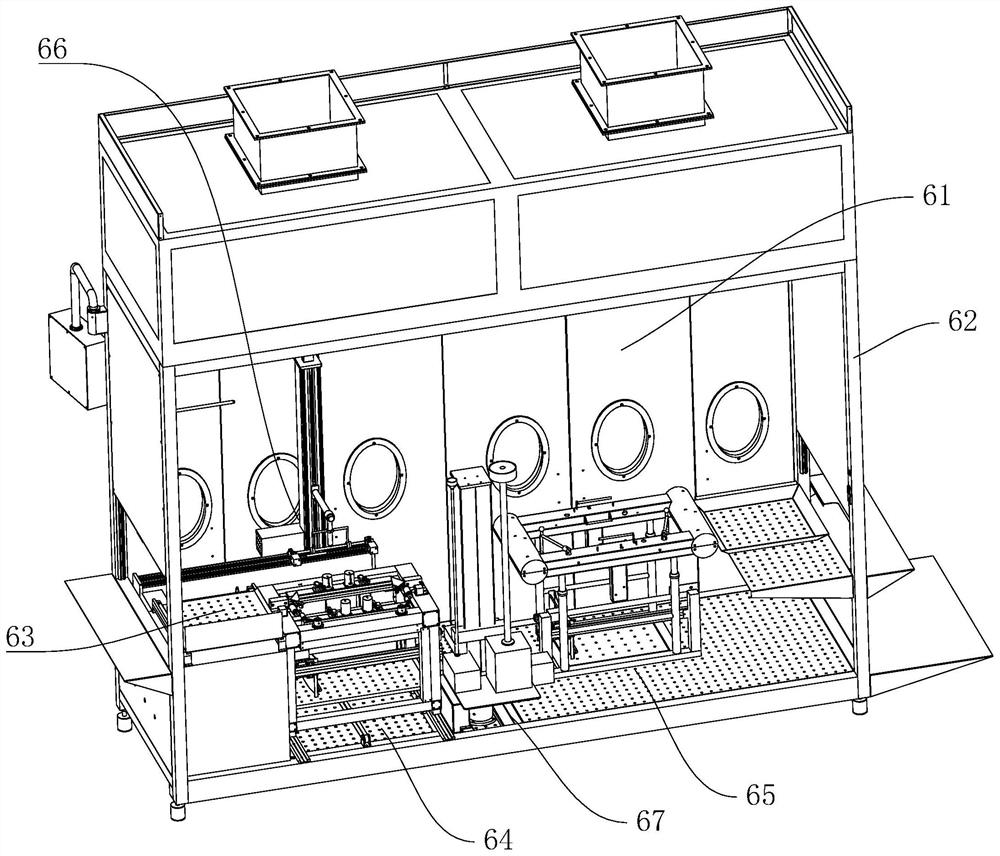

[0047] refer to Figure 1 to Figure 18 , a fully automatic double-bag packaging ORABS system with an aseptic inner bag, comprising a casing 62 with an aseptic packaging cavity 61, the aseptic packaging cavity 61 is provided with a bag placement area 63, an inner bag sealing machine 64 and an outer bag sealing machine 65, the aseptic packaging chamber 61 is provided with a grab bag transfer device 66 that transfers the bag on the bag-holding area 63 into the inner bag sealing machine 64, and the aseptic packaging chamber 61 is provided with a bag sealed by the inner bag sealing machine 64 Transported into the inner bag lifting transfer device 67 of the outer bag sealing machine 65.

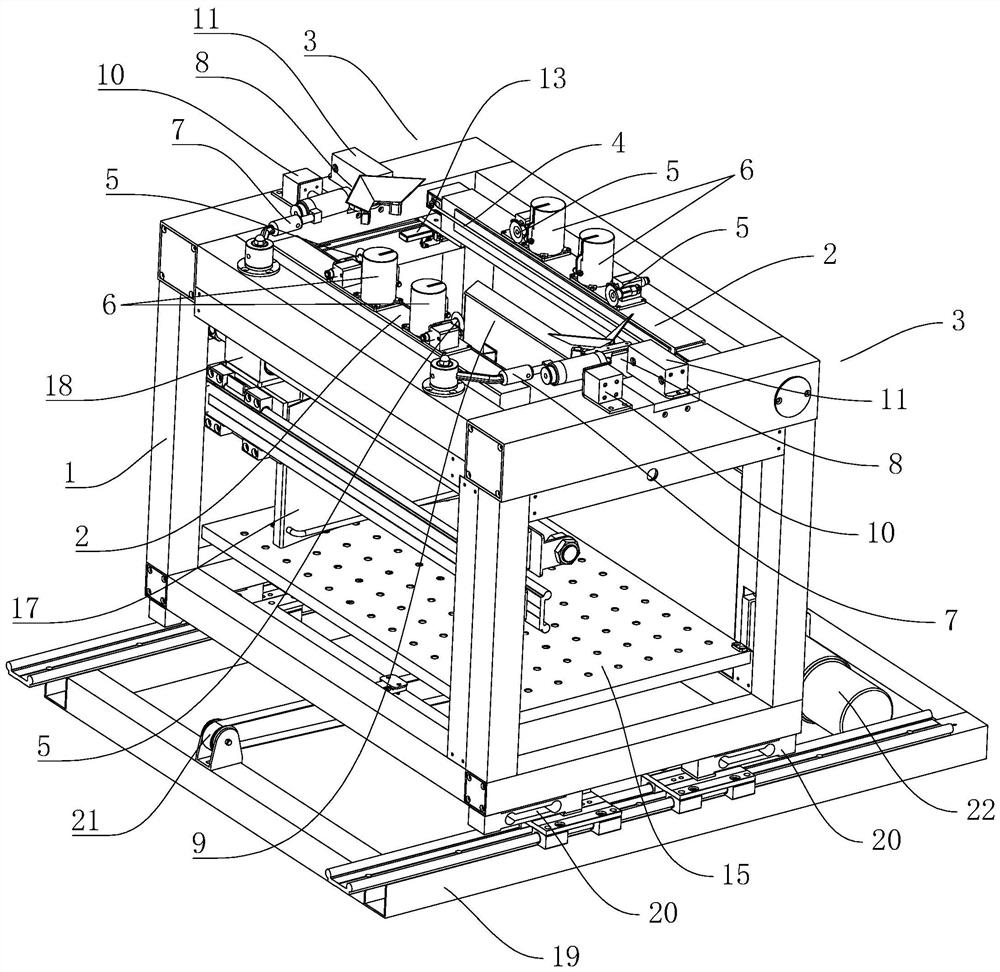

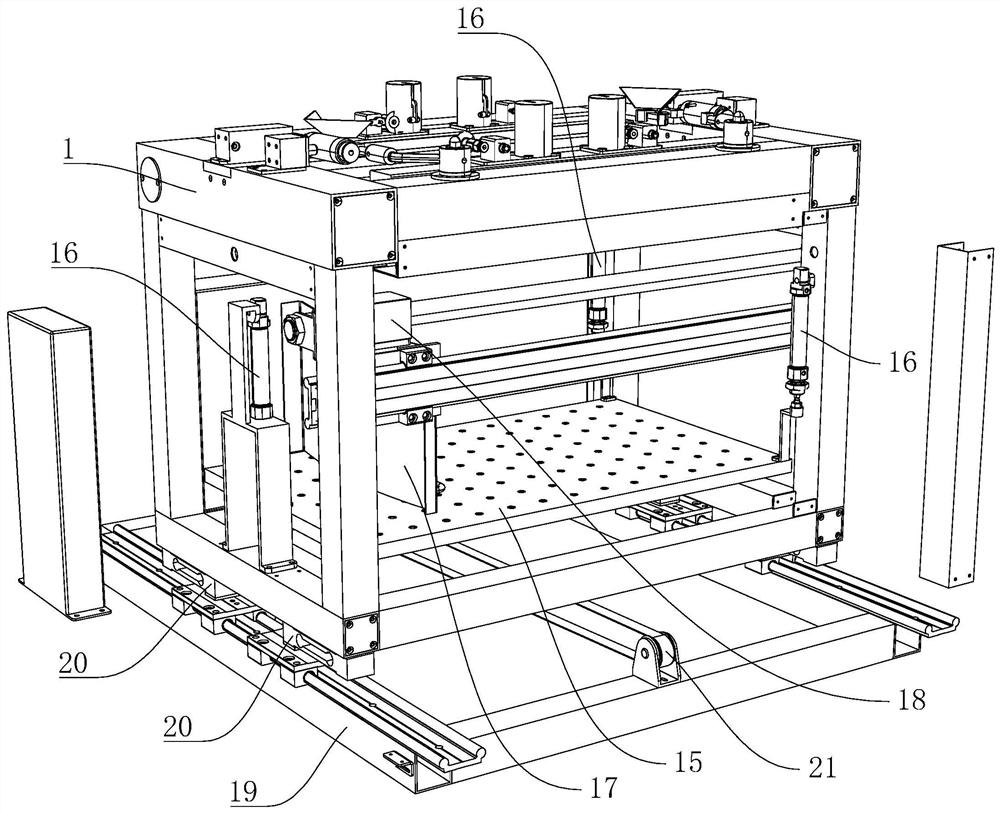

[0048] The inner bag sealing machine 64 includes a frame 1, two beams 2 slidably arranged on the second frame 1, and a transmission mechanism 3 that drives the two beams 2 to mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com