Integrated testing stand for linear motors

The technology of a comprehensive test bench and a linear motor, which is applied in the field of a linear motor comprehensive test bench, can solve the problems that the present invention is not the closest to the prior art, and achieve the effects of real-time monitoring of efficiency, synchronous adjustment, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

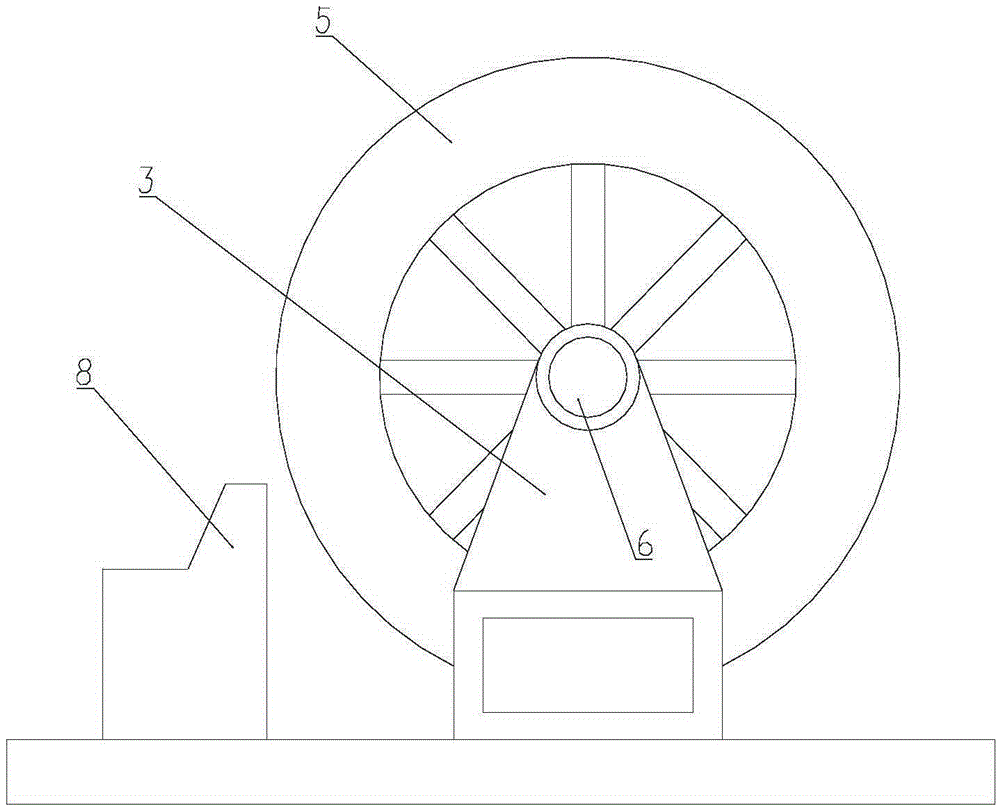

[0018] The linear motor comprehensive test bench of the present invention adopts the principle and method of a common asynchronous linear motor test with a short stator and a long rotor. The short stator with windings is fixed on the follower mechanism 7, and the long rotor adopts a steel and aluminum composite magnetic isolation structure. Inside the rotor is an induction plate, the diameter of the composite rotor is about 8 meters, and the test bench is large in size.

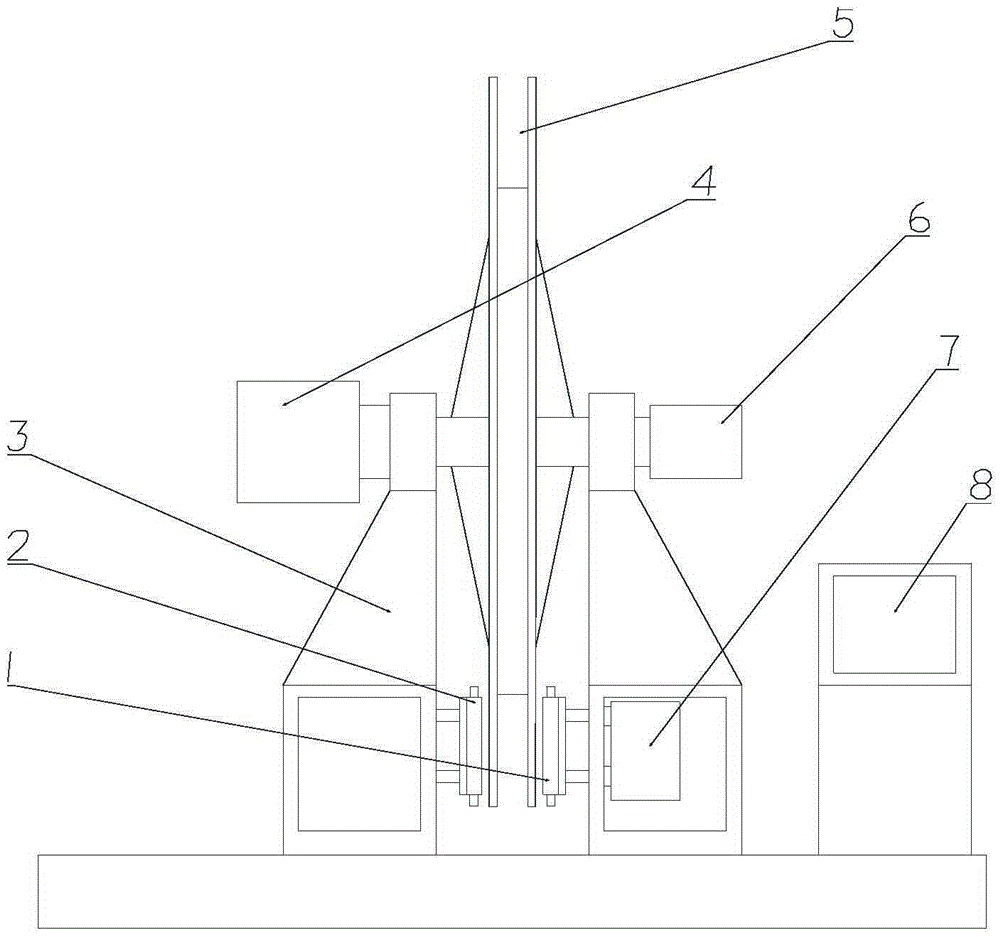

[0019] Such as figure 1 , figure 2 Shown:

[0020] Fix the linear motor, various sensors, and the rotor induction board through the mounting bracket. The air gap between the rotor induction plate and the stator is adjustable in the range of 6-15mm.

[0021] The follow-up mechanism 7 is installed on the lower part of the support base 3, and is a set of lateral sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com