Liquid carbon dioxide dry-process sand fracturing system and technological process

A liquid carbon dioxide and sand fracturing technology, which is applied in the direction of sustainable manufacturing/processing, mining fluid, wellbore/well components, etc., can solve the problems of insufficient construction displacement, large waste of liquid carbon dioxide, and high noise, and achieve improvement Improve construction safety, achieve concentrated emission, and reduce construction noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

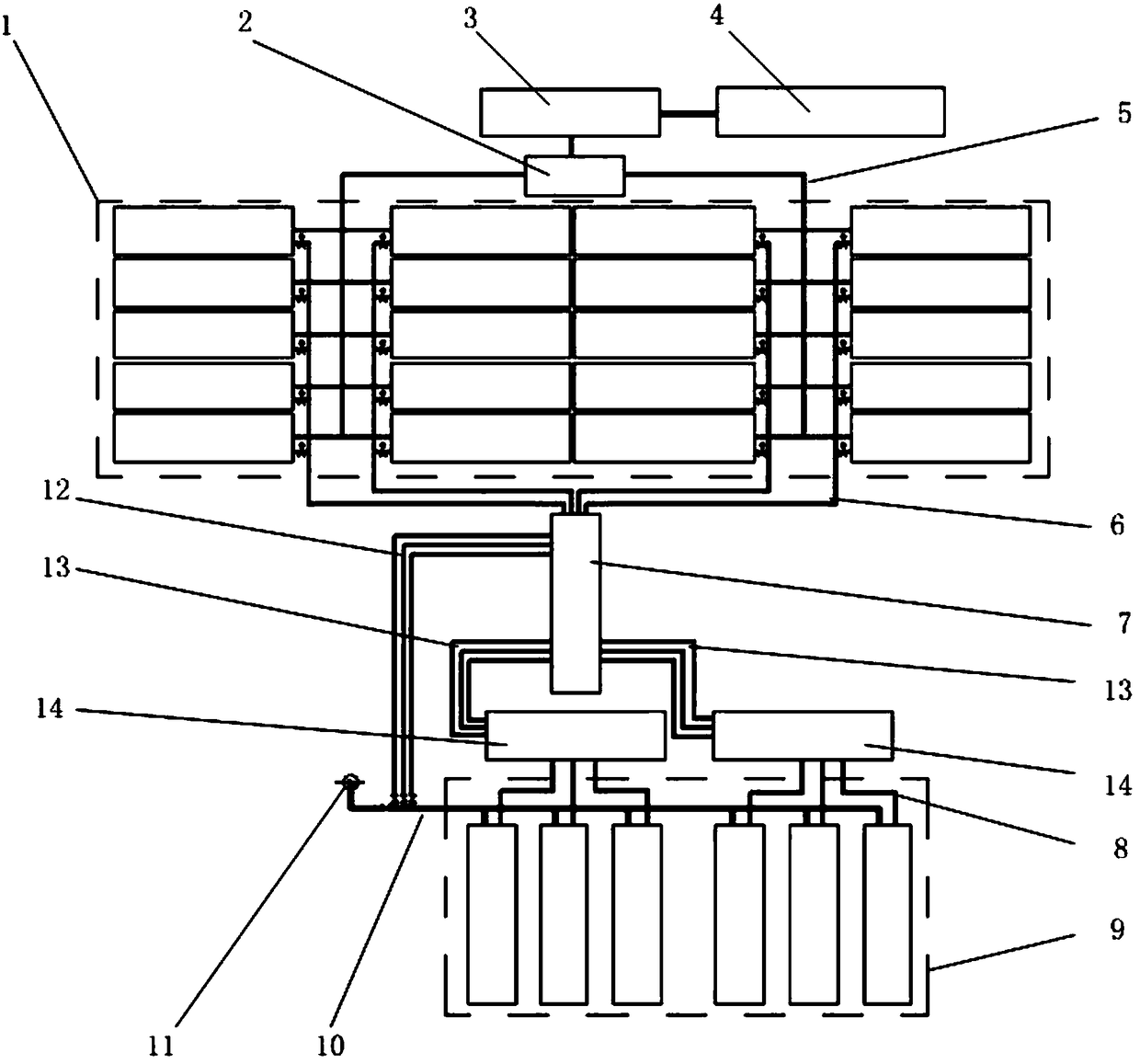

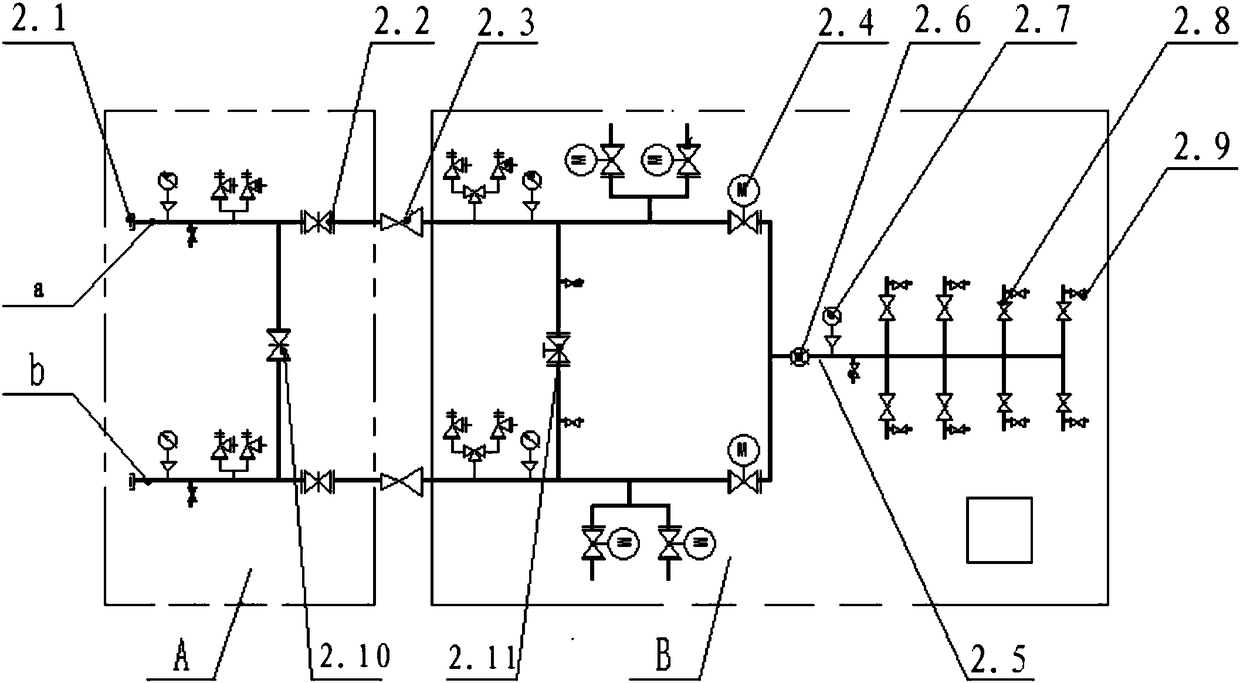

[0035] like figure 1 As shown, the liquid carbon dioxide dry sand fracturing system includes at least a liquid nitrogen tanker 4, a liquid nitrogen pump 3, a nitrogen booster 2, a carbon dioxide storage tank 1, a circulating cooling device 7, a closed sand mixing device 14 and a press The split car 9, the liquid nitrogen tank car 4, the liquid nitrogen pump car 3, and the nitrogen booster 2 are sequentially connected through pipelines, the nitrogen booster 2 is connected to the carbon dioxide storage tank 1 through the gas phase pipeline 5 of the carbon dioxide storage tank, and the carbon dioxide storage tank 1. The liquid phase pipeline 6 of the carbon dioxide storage tank is connected to the circulating cooling device 7. The circulating cooling device 7 is connected to the closed sand mixing device 14 through the liquid inlet pipeline 13 of the closed sand mixing device. The closed sand mixing device 14 is connected to the water supply pipeline 8 of the fracturing vehicle. ...

Embodiment 2

[0046] On the basis of Embodiment 1, the fracturing vehicle 9 is provided with a high-pressure pipeline 10, and the high-pressure pipeline 10 is connected to the circulating cooling device 7 through the circulating cooling device return line 12, so that the circulating cooling device 7, the closed sand mixing device 14 A circulation loop is formed with the fracturing vehicle 9 .

[0047] The nitrogen pressurization device 2, the carbon dioxide storage tank 1, the circulating cooling device 7 and the closed sand mixing device 14 are respectively connected to a remote control cabinet for remote data collection, centralized control and recording.

Embodiment 3

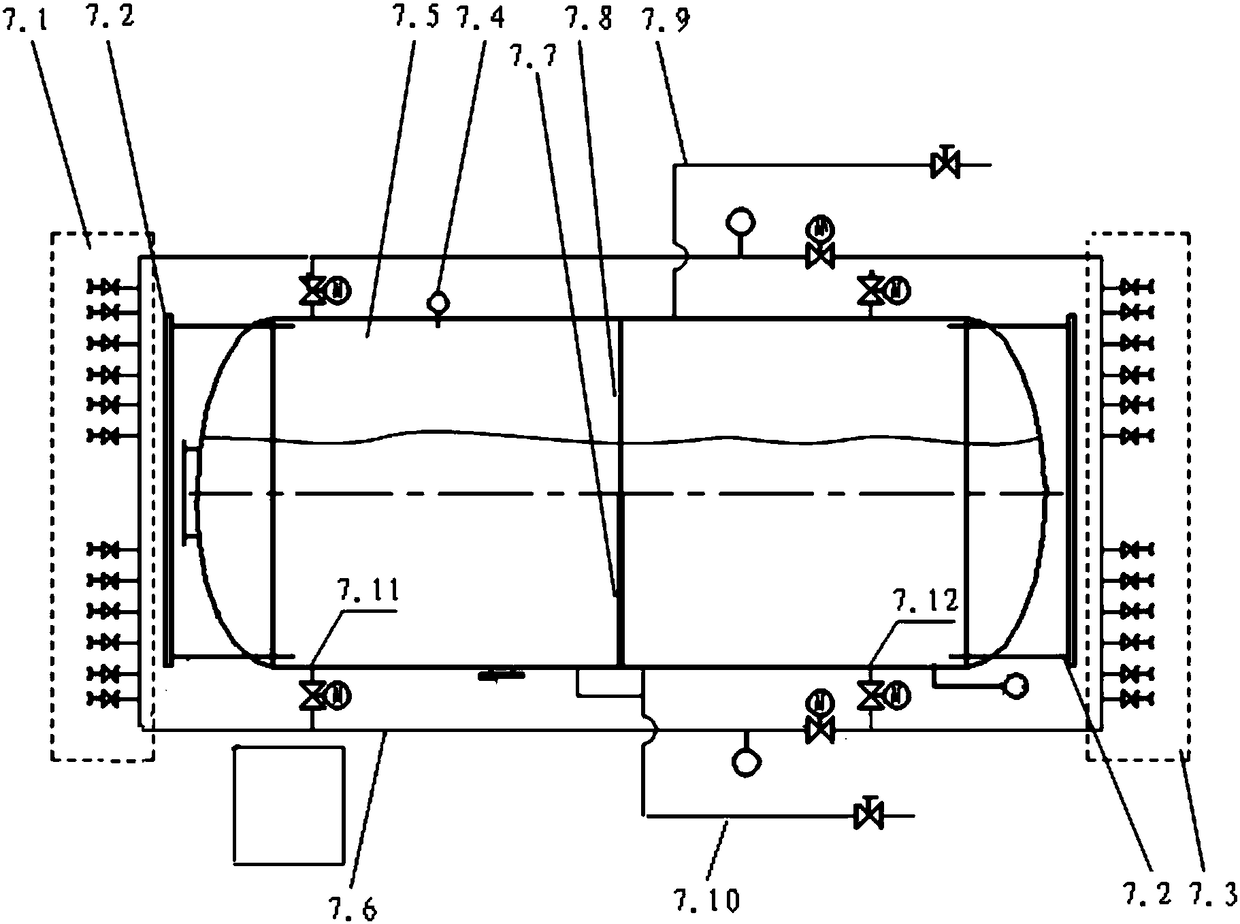

[0049] On the basis of the above examples, if image 3 As shown, the circulating cooling device 7 belongs to a horizontal layout, including a tank body 7.5, which is a professional liquid carbon dioxide storage tank, and the left and right ends of the tank body 7.5 are equipped with a liquid level gauge 7.2, and the left side of the tank body 7.5 is sealed. A manhole is provided, a pressure sensor 7.4, a safety valve, and a gas phase pipeline 7.9 are provided on the top of the tank body 7.5, a partition 7.7 is provided at the bottom of the tank body 7.5, and a walkway that can be opened and closed is provided on the partition 7.7. A filter screen 7.8; a temperature sensor is provided at the bottom of the tank body 7.5, and residual liquid discharge ports are provided on both sides of the bottom partition plate 7.7 of the tank body 7.5, and the two residual liquid discharge ports are combined into a residual liquid discharge pipeline 7.10;

[0050] A liquid inlet 7.11 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com