Construction method of reinforced concrete jacked pipe underground T-shaped butt joint

A reinforced concrete pipe, reinforced concrete technology, applied in the direction of pipes/pipe joints/pipe fittings, pipe laying and maintenance, machinery and equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further illustrated below by specific examples.

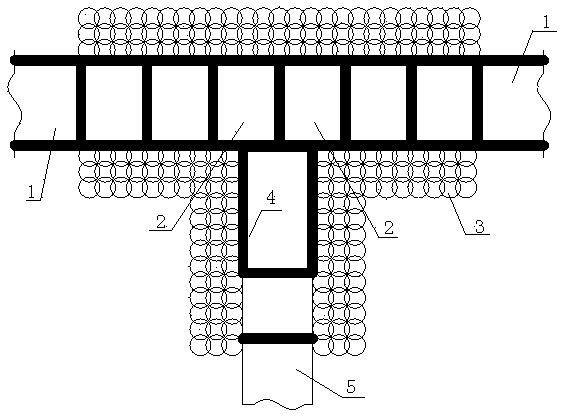

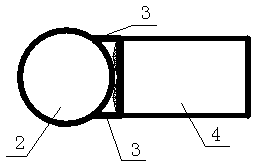

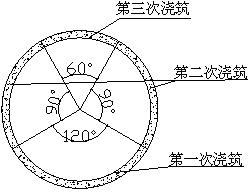

[0022] Such as figure 1 , figure 2 and image 3 As shown, two sections of reinforced concrete jacking pipes 1 and 5 (with diameters of 2.7m and 2.2m respectively) are jacked from different directions. The reinforced concrete pipe jacking 1 with a diameter of 2.7m is vertically connected, and the reinforced concrete pipe jacking 2 with a diameter of 2.2m is connected with the pipe jacking 1 with a diameter of 2.7m in an underground T-shape. The specific steps are as follows:

[0023] Step 1. First carry out the construction of the pipe jacking well involved in the underground docking, and then number the sections of the longitudinally penetrating reinforced concrete pipe jacking 1 (2.7m in diameter) on the drawing. The section that is jacked first is the first section, in order Arrange, find out the numbers of the 2 sections of reinforced concrete pipe 1 at the T-shaped docking position, and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com